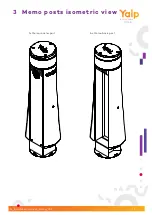

EN_Installation manual_Memo_v2.9

- 6 -

4 Foundation

Yalp suggests four standard mounting options. Choose the appropriate foundation method for your

situation. For surfaces other than concrete, such as tiles, please contact our foundation installation team

for specific support. Please request your specific installation drawing at Yalp. This information will come

to you in a separate document.

Product nr.

When used?

Description

YA3930D

Used outdoor. The anchors are deposited

together with the concrete into the

ground. Please note; it is important to

pour the concrete one week before the

Memo is mounted.

-Deep mount-

7x deep mounting ground

anchors.

Included: PVC tubes to conduct

the cables.

YA3930S1

Cables are milled in the floor.

Option for indoor use only,

used in

combination with wet pour.

-Surface mount milling-

7x installation plate and anchors

Included: protective tubes to

conduct wires. Ø40mm with

cord. [1.6”]

YA3930S2

Suitable for indoor use only on

combination with wet poor. Option

for places in with milling in the floor is

impossible.

-Surface mount without milling-

7x installation plates and

anchors.

Included: protective tubes to

conduct wires. Ø40mm with

cord. [1.6”] The cables will be in

a dome on the floor. (Plates are

higher leveled than YA3930S1.)

YA3930S3

For definitive outdoor placing (tiles on

top) or for exhibitions, when there can

not be milled any deeper than 150mm

(1.6yards) into the ground. To be placed

in sand or on flat concrete.

-Spider mount-

7x installation plates and steel

tube mounted together as one

solid construction. The spider

frame is positioned 100-150 mm

underground. [3.9-5.9”]Tiles can

be placed over the construction.

YA3930E

Temporary fixation. No milling or

attachment to floor

-Exhibition-

Ask Yalp for possibilities, several

options available