6

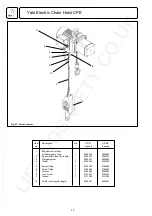

1.) Unscrew the locking nuts (item 9) and hex. nuts (item 2)

from the crossbars (item 1) and remove both side plates

2.) Measure the flange width of the beam (see Fig. 1 1 -

3.) Adjust measurement "B" between the shoulders of the

round nuts (item 5) on the threaded crossbars (item 1).

Ensure that the 4 bores in the round nuts face towards the

outside. Adjust the measurement "B" to equal measure-

ment "b" plus 4 mm. Measurement "A" must be 2 mm on

either side and the suspension traverse (item 4) must be

centred between the round nuts.

4.) Replace one side plate (item 6):

Replace one side plate ensuring that the roll pins (item 8)

engage into one of the bores in the round nuts. To achieve

this it may be necessary to rotate the round nuts slightly .

5.) Replace the washers (item 3) and tighten the hex. nuts

(item 2). Screw on the locknuts (item 9) fingertight and

tighten a further 1/4 to 1/2 turn.

The locknuts must always be fitted.

6.) Loosely replace the second side plate (item 6) on the

crossbars (item 1). The washers (item 3), hex. nuts (item2)

and locknuts (item 9) can be fitted loosely .

7.) Raise the complete pre-assembled trolley to the carrying

8.) Engage the second side plate (item 6) ensuring that the

roll pins (item 8) engage into one of the bores in the round

nuts (item 5). To achieve this it may be necessary to rotate

9.) Tighten the hex. nuts (item 2) on the second side plate.

Tighten the locknuts (item 9) fingertight and then a further

The locknuts must always be fitted.

To fit the hand chain position the slot on the outer edge of

the hand chain wheel below the chain guide. Place any

one link of the endless hand chain vertically into the slot

and turn the hand chain wheel until the link has passed

the chain guides on both sides.

Do not twist the hand chain when fitting.

Geared trolleys are moved by pulling the hand chain.

Work at electrical installations may be carried out by

electrical experts only. The local regulations have to be

strictly observed, in Germany DIN 7100 / VDE 0100 and

• Before beginning work on electrical components the

mains current switch must be switched OFF and secured

against unintentionally being switched back on.

• Before connecting the chain hoist ensure that the

electrical data on the nameplate match the local supply

• The mains supply cable must be an insulated cable with

4 flexible leads. The ground (earth) lead must be longer

than the live leads. For wire cross-section and fusing see

• The length of the pendant control cable is determined by

working conditions. Attach the tension relief wire in a manner

that the pendant control cable hangs load-free.

• Wiring and terminal connecting diagrams are included

1.) The mains supply cable must be connected to the

electric chain hoist before it is connected to the mains

2.) On chain hoists with an electric trolley (CPE-VTE) the

three phases of the mains supply are to be connected to

the terminal strip within the terminal box on the trolley. The

ground/earth wire is to be connected to the special ground/

earth connection within the terminal box of the chain hoist.

3.) On chain hoists without electric trolley the mains supply

and the ground/earth wire are to be connected to the

terminal strip within the terminal box of the chain hoist.

4.) After removing the terminal box cover, connect the wiring

as shown on the wiring diagram label inside the terminal

On hoists with direct control the ground/earth

wire should always be connected according to the wiring

diagram. Should the mains supply source not provide a

ground (earth) connection please consult the manufacturer.

5.) After replacing the terminal box cover, connect the other

end of the supply cable to the mains supply .

6.) Check the motor's direction of rotation.

The wiring diagram included has been drawn for a normal,

clockwise rotating installation.Should the user's mains

supply not fulfil these requirements, e.g. the hoist lowers

when lift is selected (or vice versa) switch the unit OFF

immediately and exchange two of the three phase

connections in the mains connection.