4

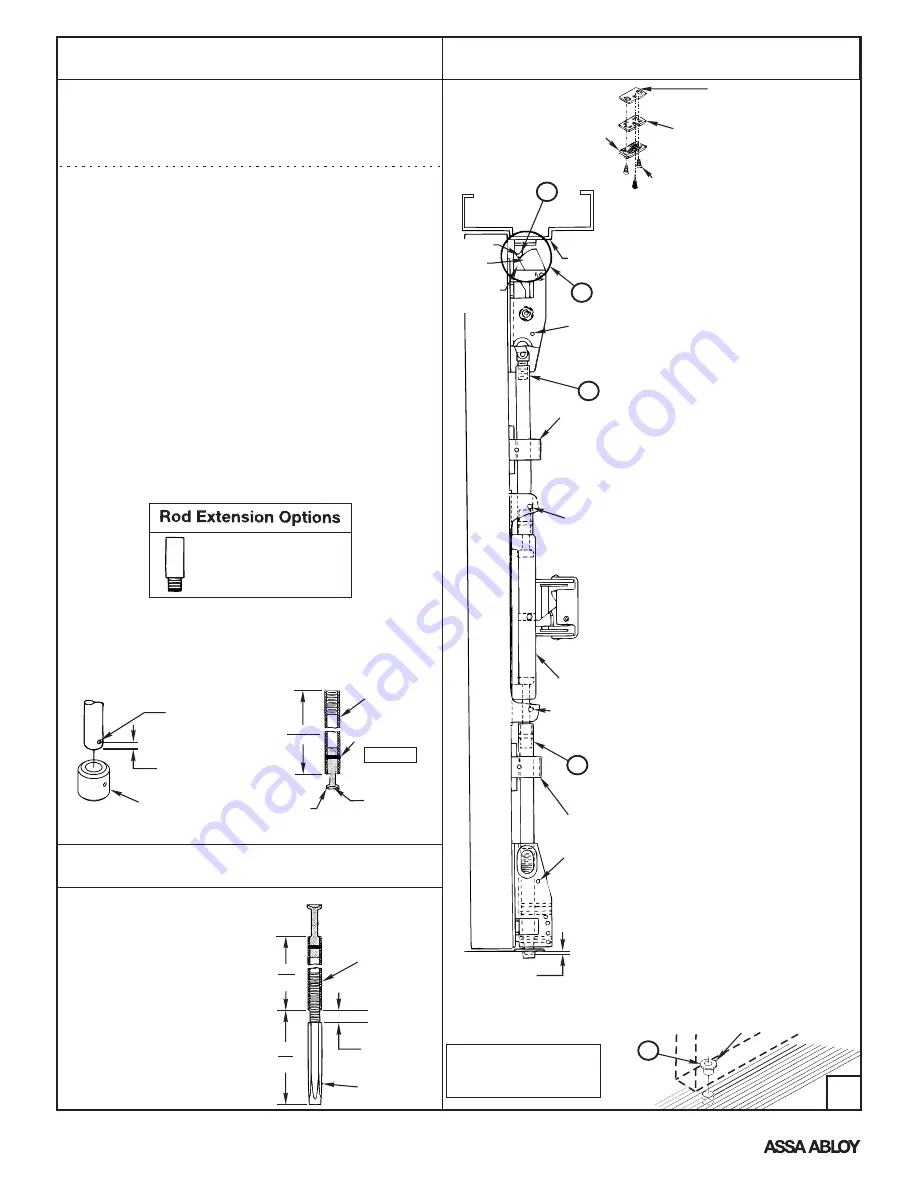

7. Complete Installation

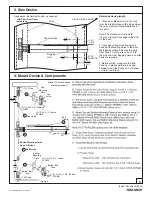

5. Rod Preparation & Assembly

A. Top Rod Sizing

1. For openings under 7' (2134mm), subtract the actual

opening height from 7' (2134mm).

Example: 6'8" (2032mm) opening

7'0" (2134mm) - 6'8" (2032mm)

= 4" (102mm)

Top Rod must have 4" (102mm) cut from end with

1/8” (3mm) thru hole. Use attached drill fixture to

locate and re-drill 1/8" (3mm) dia. hole thru the

top rod. Make sure rod bottoms out inside drill fixture

prior to drilling. (See Figure 5A).

2. For opening over 7' (2134mm), subtract 7' (2134mm)

from the actual opening height.

Example: 7'6" (2286mm) - 7'0" (2134mm)

= 6" (152mm).

Top Rod must have a 6" (152mm) extension added

to length (See below for available rod lengths).

B. Assemble Top Rod

Insert Top Rod Connector into sized Top Rod and Install

1/8" (3mm) x 1/2" (13mm) Roll Pin thru both pieces until

flush on both sides. (See Figure 5B).

Top Rod

Flat Face

(2 Sides)

Top Rod

Connector

Flush

1/8" (3mm)

x 1/2" (13mm)

36-1/8

(918)

1/8

(3)

Drill Fixture

3/8

(10)

Figure 5B: Top Rod Assembly

Figure 5A: Drill Pin Hole

Note:

Below listed instructions are based on a device

mounted 39-15/16" (1014mm) from finished floor

or threshold. Any deviation on device mounting

height must be accommodated to insure proper

device function.

6. Bottom Bolt Assembly

A.

Thread Bottom Bolt into Bottom

Rod Assembly.

B.

Leave 1/2" (13mm)

for adjustment.

Bottom Rod

Assembly

Bolt

1/2

(13)

3-7/8

(98)

32-1/4

(812)

Adjustable

(Ref.)

Bolt

Engagement

Frame

Stop

Rod Guide

A2

A

3/8"

(10)

Cover

Screw

Hole

Cover

Screw

Hole

Cover

Screw

Hole

Cover

Screw

Hole

Note:

Bottom Bolt will retract to

1/8" (3mm) above Floor Strike.

Floor covering in the door path

must be laid out accordingly.

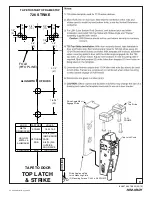

Top Strike Detail

Shim

(2) Supplied (Start With One)

Strike Plate

(Ridges Face Down)

791 Strike

(3) 10-24 x 3/4" (19mm) PFHMS

B2

790 STRIKE

(Press in place)

A. Install Top Rod and 791 Strike

1.

Thread Top Rod Assembly onto Top Latch.

Lift rod to fully retract Top Latchbolt.

Depress Pushpad and hold depressed.

Adjust top rod length until Rod Connector

seats into the Slide Assembly in latch case.

Note:

For 7170 devices, skip section (2a)

and 2(b). See the installation instructions

for the 726 strike on page 9.

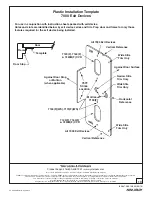

2a. Position the Top Strike Roller between

the Tripping Lever and the Bolt on the

Top Latch. Verify hole positions and

prepare holes per Installation Instruction

Template.

b. Install Top Strike and Strike Plate using

(2) #10-24 x 3/4" (19mm) PFHMS thru

outer slots. Adjust and shim strike as

needed for zero door rattle. Add third

screw (#10-24 x 3/4" (19mm) PFHMS)

after final adjustments.

3. If Top Bolt does not remain retracted when

door is opened, Top Rod is too short. Pull

rod out of the guide and the slide then

rotate rod to increase length. Upper Bolt

should retract flat.

4. If upper latch will not deadlock, Top rod

is too long. Pull rod out of the guide and

the slide and rotate to decrease length.

* If 7170 LBR, skip section B.

B. Install Lower Rod and 790 Strike

1. With door open, actuate Pushpad to

retract upper latch. Hang Lower rod

from bottom of Slide and adjust bolt so

that it clears the finished floor by 1/4".

2. Verify location of pipe strike template.

Prepare the strike hole and install the

pipe strike. Set in place with appropriate

bonding material.

3. With the door open, actuate pushpad

to retract upper latch. Adjust bolt

height by pulling the rod out of the

guide and slide and rotating until the

bolt clears the pipe strike by 1/8".

C. Test device action by Touchbar,

by Trim, by Dogging

D. Install covers

A1

B

Rod Guide

Slide

Roller

Bolt

Tripping

Lever

60-1510-0280: 2" (51mm)

60-1510-0277: 6" (152mm)

60-1510-0278: 12" (305mm)

(Specify Device Finish)

An ASSA ABLOY Group brand

80-9470-0010-000 (03-13)