A

D

2

INSTALLATION –

TOOLS NEEDED:

One (1) tube cutter, one (1) pencil, one (1) flathead

screwdriver, one (1) adjustable wrench and two (2)

pipe wrenches.

The Series 67 and Series 767 low water cut-offs are

float-type boiler controls designed to interrupt current

to the burner whenever the water drops to the cut-off

level.

The Series 767 is identical to Series 67 in all

respects except one. The Series 767 is equipped with

a 2-1/2" (63.5mm) pipe tap opening in the body, and

does not require the quick hook-up fittings supplied

with the Series 67. The pipe tapping allows for a

direct connection to the side of the boiler.

Electrical Ratings

Pump Circuit Rating (Amperes)

Voltage

Full Load

Locked Rotor

Pilot Duty

125 VA at

120 or 240 VAC

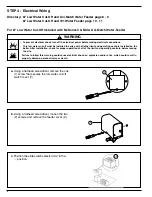

For Series 67 -

The elevation of the control (A)

is already determined by the location of the

gauge glass tappings (B,C) on the boiler. The

horizontal cast line (D) should be located at or

above the boiler manufacturer's minimum safe

water level (E).

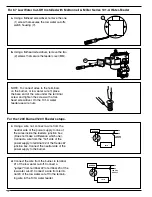

For Series 767 -

The elevation of the control (A)

is already determined by the location of the 2-

1/2 (63.5mm) pipe tapping on the boiler. The

horizontal cast line (D) of the body (A) should

be located at or above the boiler manufacturer's

minimum safe water level.

STEP 1 - Determine the Elevation at Which the

Low Water Cut-Off Controller Must be Installed

C

A

E

B

D

IMPORTANT:

Follow the boiler manufacturer's

instructions along with all applicable codes and

ordinances for piping, blow down valve and water

gauge glass installation.

OPERATION

Maximum Steam Pressure:

20 psi (1.4 kg/cm

2

)

Series 67

Series 767

Note: 11 MV is rated at 24 VA @ 24 VAC to 120 VAC

120 VAC

7.4

44.4

240 VAC

3.7

22.2