14

TECHNICAL APPENDIX

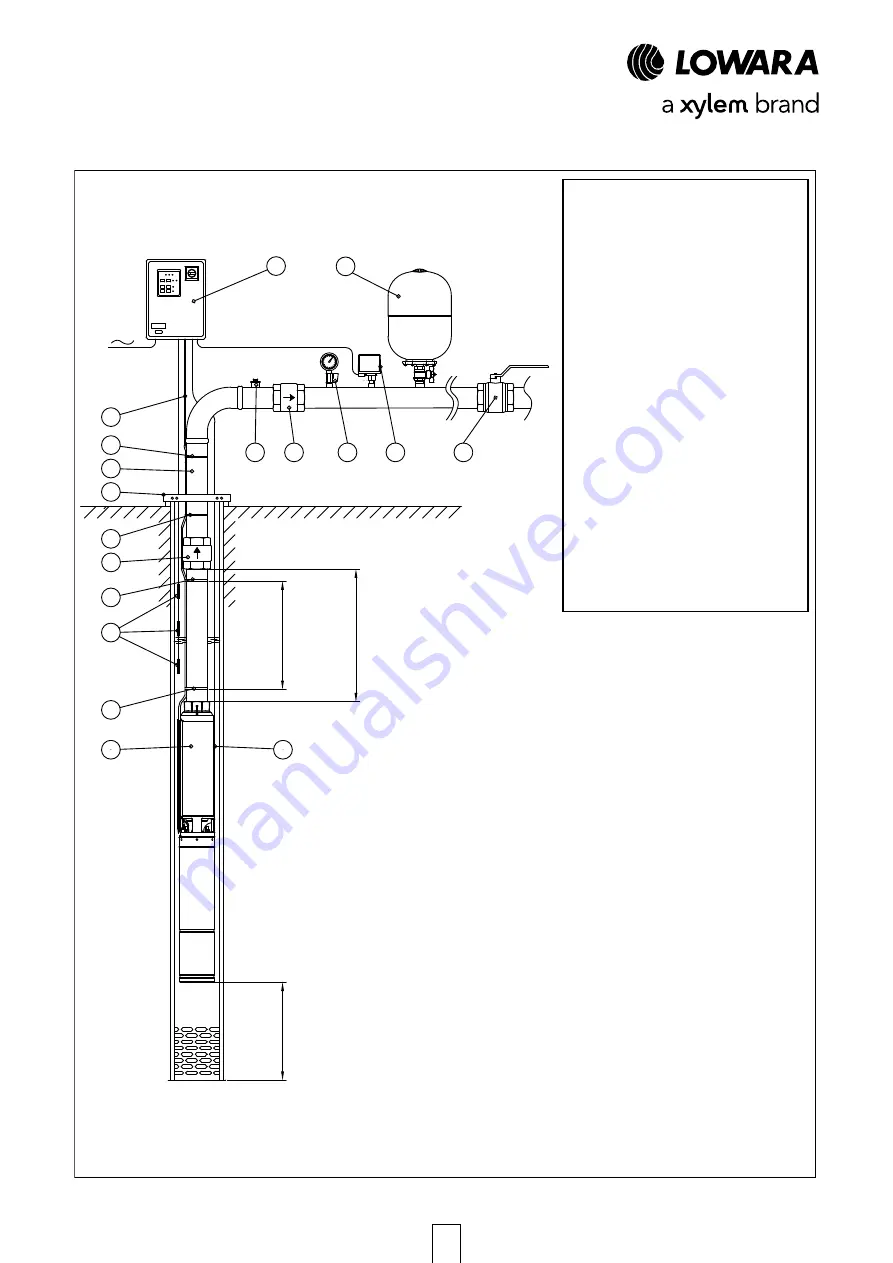

SUBMERSIBLE ELECTRIC PUMP INSTALLATION

DIAGRAM

1 - Submersible electric pump.

2 - Cable clamp.

3 - Level sensors for protection

against dry running.

4 - Non-return valve.

5 - Support bracket.

6 - Delivery pipe.

7 - Electrical cable for

motor power.

8 - Electric pump bleed/

priming cap.

9 - Pressure gauge.

10 - Diaphragm tank.

11 - Gate valve.

12 - Control panel.

13 - PTC/PT100 cable.

14 - Pressure transducer.

A - Distance between the clamps

that secure the drop cable

to the delivery pipe.

B - Distance from the bottom of

the well to the electric pump.

COMPONENTS REQUIRED FOR

CORRECT INSTALLATION

•

Control panel equipped with a main switch and thermal

relay for overload protection.

•

Non-return valve at 10 meters’ distance from the delivery

ports, plus an additional non-return valve every 30÷50

meters of piping.

•

Gauge and gate valve at well mouth.

•

Electronic probes or floats for protection against dry

running.

•

Secure the drop cable to the pipe every 2÷3 meters of

piping.

•

Make sure the electric pump is installed at a safe

distance from the bottom of the well.

•

Make sure there is a minimum distance of 3 mm

between the diameter of the pump and the internal

diameter of the well.

•

During operation, make sure that the water circulation

speed around the motor is at least 8 cm/sec.

•

Make sure that the minimum dynamic level of the water

in the well is at least 1 m above the pump’s delivery port.

A0033_B_SC

7

4

6

3

2

2

2

10 m

3 m (A)

1 m (B)

2

1

13

10

5

12

9

4

8

11

14

Summary of Contents for Lowara Scuba SC205C

Page 1: ...Cod 191005661 Rev A Ed 06 2017 50 Hz SCUBA Series CLOSE COUPLED SUBMERSIBLE ELECTRIC PUMPS ...

Page 2: ......

Page 13: ...13 TECHNICAL APPENDIX ...

Page 29: ...29 ...

Page 30: ...30 ...

Page 31: ......