en - Translation of the original instructions

• Liquids not compatible with the pump construction materials

• Hazardous liquids (such as toxic, explosive, flammable, or corro-

sive liquids)

Standard/

Optional

Material

code

Material

casing/

impeller

EN733

range

Extension

range

32

–125 to

150-400

200

–250,

200

–315,

250

–315

• Potable liquids other than water (for example, wine or milk)

Examples of improper installation:

• Hazardous locations (such as explosive, or corrosive atmos-

pheres).

• Location where the air temperature is very high or there is poor

ventilation.

• Outdoor installations where there is no protection against rain or

freezing temperatures.

Standard

Standard

Standard

CC

CB

CN

Cast iron /

Cast Iron

X

X

X

Cast Iron /

Bronze

Cast Iron /

Stainless

Steel

DANGER:

Do not use this pump to handle flammable and/or explosive

liquids.

Standard

Standard

Standard

DC

DB

DN

Ductil Iron /

Cast Iron

X

X

X

NOTICE:

Ductil Iron /

Bronze

• Do not use this pump to handle liquids containing abrasive, solid,

or fibrous substances.

• Do not use the pump for flow rates beyond the specified flow

rates on the data plate.

Ductil Iron /

Stainless

Steel

Special applications

Standard

Optional

NN

RR

Stainless

Steel / Stain-

less Steel

X

X

Contact the local sales and service representative in the following cas-

es:

• If the density and/or viscosity value of the pumped liquid exceeds

the value of water, such as water with glycol; as it may require a

more powerful motor.

Duplex / Du-

plex

X

• If the pumped liquid is chemically treated (for example softened,

deionized, demineralized etc.).

3.6 Mechanical seal

• Any situation that is different from the ones that is described and

relate to the nature of the liquid.

Unbalanced single mechanical seal acc. EN 12756, version K Dimen-

sions. See

Table 10

.

3.2 Pump description

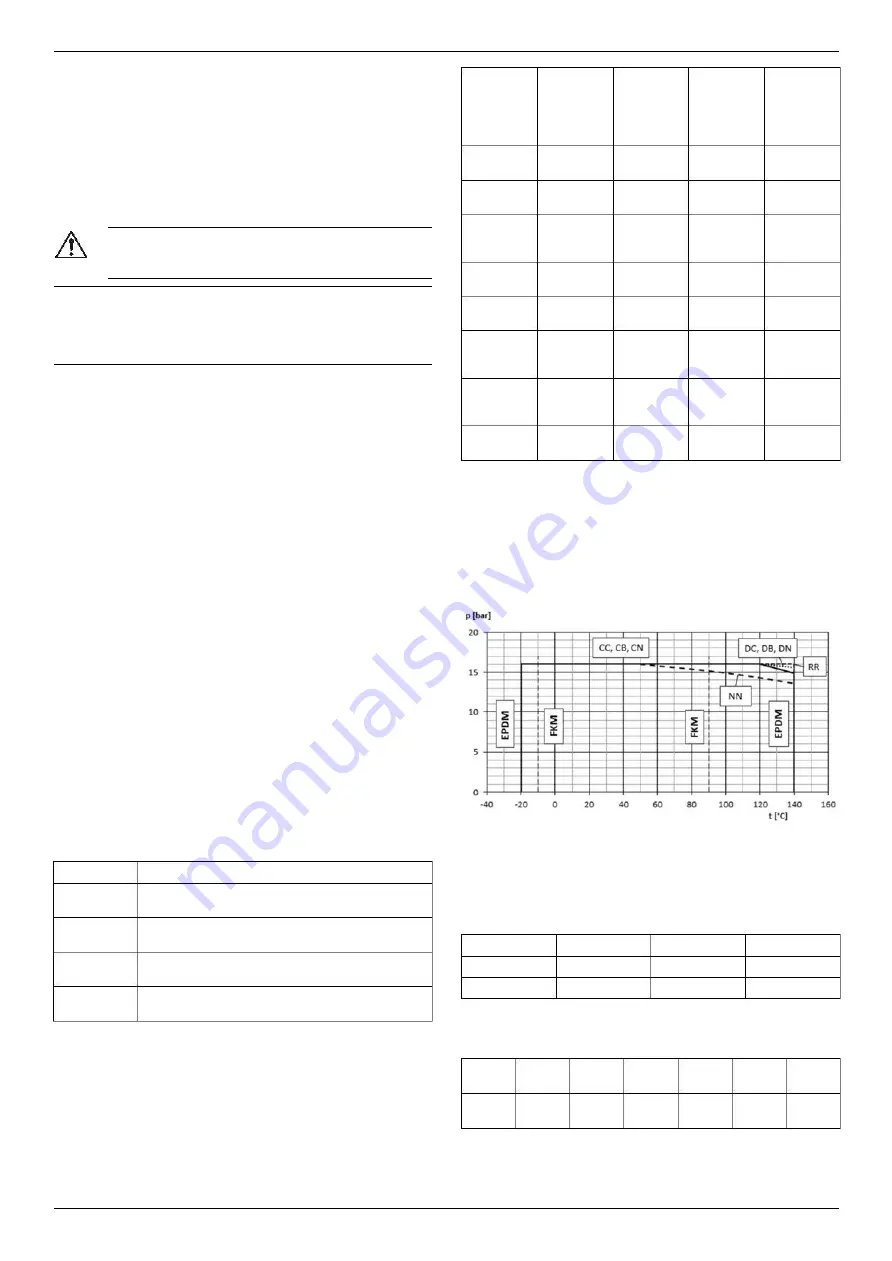

3.7 Application limits

See

Figure 6

for an explanation of the description code for the pump

and one example.

Maximum working pressure

This flow chart shows the maximum working pressure depending on

the pump model and the temperature of the pumped liquid.

3.3 Nameplate

The nameplate is a metal label that is located on the bearing bracket.

The name plate lists key product specifications. For more information,

see

Figure 7

The nameplate provides information regarding the impeller and casing

material, the mechanical seal and their materials. For more informa-

tion, see

Figure 8

.

IMQ or TUV or IRAM or other marks (for electric pump only)

Unless otherwise specified, for products with a mark of electrical-relat-

ed safety approval, the approval refers exclusively to the electrical

pump.

3.4 Design structure

• Dimensions according EN 733 and additional not standardized

extension sizes

• Volute casing pump with back pull out power end

• Single stage

• For horizontal assembly

P

1max

+ P

max

≤ PN

P

1max

P

max

PN

Maximum inlet pressure

Part

Description

Maximum pressure generated by the pump

Maximum operating pressure

Casing

• Radial split volute casing with radial discharge

• Replaceable wear ring

Liquid temperature intervals

Impeller

• Closed radial impeller with wear rings on both

sides

Version

Standard

Optional

Gasket

Minimum

Maximum

Shaft seal

Bearings

• Single mechanical seal acc. EN 12756

• Optional cartridge mechanical seal

EPDM

-20°C (-4°F)

-10°C (14°F)

140°C (284°F)

90°C (194°F)

FPM (FKM)

• Radial ball bearings of motor

• Grease lubrication

For special requirements, contact the Sales and Service Department.

See the sectional drawing

Figure 9

.

3.5 Material

kW

0.25 -

3.00

4.00 -

7.50

11 - 22 30 - 37 45 - 75 90

– 160

The metallic parts of the pump that come in contact with water are

made of the following:

Starts

60

40

25

16

8

4

per hour

Noise level

See the measuring surface sound pressure levels L

pA

in

Table 11

.

5

e1631 Installation, Operation, and Maintenance Manual

Summary of Contents for Lowara e1631

Page 1: ...K20040028 REV 0 ...

Page 27: ...Technical appendix 28 e1631 Installation Operation and Maintenance Manual 27 ...

Page 32: ......