Requirements

These requirements apply for electrical installation:

• All fuses and circuit breakers must have the proper rating, and comply with

local regulations.

• The cables must be in accordance with the local rules and regulations.

5.2 Connect the controller

Some of the connection terminals are configurable. For more information, see

the System Installation and Operation Manual.

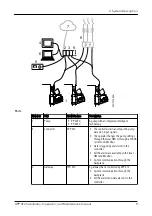

5.2.1 Connect a single unit

This instruction describes all connection possibilities. Some of them are

optional. Connect only one HMI.

PWR

RS485

DI

1

2

3

4

GND

A

AI

AO

HMI

1

2

3

4

5

B

GND

24VDC

+

_

+

_

+

_

DI1

DI2

DI3

DI4

DO1

DO2

DO3

DO4

ALARM A

ALARM B

RUN

COMMS

RS485

USB

NODE

ADDRESS

ON

OFF

MASTER

SLA

VE

TERM

DO1

NO

COM

NO

COM

T4

T3

GND

DO2

DO3

NO

COM

NO

COM

DO4

ETHERNET

4

7

8

3

9 0

6

1

2

5

WS011126A

3 4 5

8

6

7

1

2

FPG

4xx

1. Analog input and output

2. Digital inputs

3. HMI, FOP 315

4. RS-485, Modbus RTU

5. + 24 VDC

6. Digital outputs

7. T3, T4

8. Ethernet

Mixer or pump

1. Connect the T3 and T4 cables from the mixer or the pump to the T3, T4

terminal.

Create as much separation as possible between the power cores and the

control cables. Keep the T3 and T4 cables twisted and shielded as close to

the terminals as possible.

Ethernet

2. Connect the Ethernet cable to the Ethernet terminal.

It is possible to use the Ethernet terminal for multiple communication

options:

– Communication with FOP 402

– Communication with SCADA systems through Modbus TCP

If the Ethernet terminal is used for multiple communication options, then use

an Ethernet switch.

– The Ethernet cable must fulfill category 5.

– For more information about the Modbus interface, see separate

documentation.

5 Electrical Installation

16

APP 412 Installation, Operation, and Maintenance manual