Reviews:

No comments

Related manuals for VESDA VLC

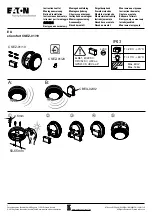

xComfort CSEZ-01/19

Brand: Eaton Pages: 6

Excalibur Gold Series-1200atv

Brand: Omega Pages: 7

WT 519

Brand: Techno Line Pages: 102

SM3531B

Brand: Smartro Pages: 9

SCO5LB

Brand: First Alert Pages: 2

317485 1904

Brand: Auriol Pages: 81

MVT380

Brand: MeiTrack Pages: 7

CK3-1

Brand: Lucid Technologies Pages: 33

SF804

Brand: EVERSPRING Pages: 13

18202077

Brand: Char-Broil Pages: 32

49-467

Brand: Radio Shack Pages: 4

Boomerang SF 6P150

Brand: SETRONIC VERONA Pages: 4

Boomerang S 6P150

Brand: SETRONIC VERONA Pages: 4

SS-5080A

Brand: HoMedics Pages: 30

EM3529-NO RCC

Brand: Clas Ohlson Pages: 5

SLR-E-IS

Brand: Hochiki Pages: 2

AviStart 6001

Brand: Avital Pages: 20

Hurricane 3

Brand: Avital Pages: 25