https://www.XPOtool.com

Item 63342, 63343, 63344, 63345, 63346, 63347

Page 8

The Tool Experts

05 2022

-1

8.

Turn the pump off and set the control valve to “FILTER.”

9.

Make sure that all suction lines and RETURN lines are open to allow the water to flow freely

from the pool and back to the pool.

10.

STAND CLEAR OF THE FILTER and turn the pump on.

11.

The filter now begins the filtering cycle. Make sure that the water returns to the pool and observe

the operating pressure of a clean water.

6.

The filter pressure in step 11 must not exceed the pressure read during commissioning of the

filter. If after backwashing the starting pressure is 0.3–0.4

bar (4–6

psi) higher than then normal

starting pressure, the sand must be cleaned chemically.

Storage during winter

Attention!

If water freezes inside the system, the total system will be damaged. Then, water might

flow out, causing flooding and damages! — In regions with freezing winter temperatures, the pool and

all its components must be stored during the cold season to avoid any damage.

1.

Perform backwashing of the sand filter.

2.

After backwashing, turn the pump off and set the control valve to the “WINTER” position.

Warning!

The multi-port control valve must be left to the “WINTER” position during shut-

down season. If the control valve is not left to the “WINTER” position, water might leak, causing

damages.

3.

Remove the drain cap on the bottom of the filter tank and leave the cap off during the winter.

Completely drain the filter tank.

4.

Drain and prepare the pump for wintering.

5.

Drain all pipes and hoses.

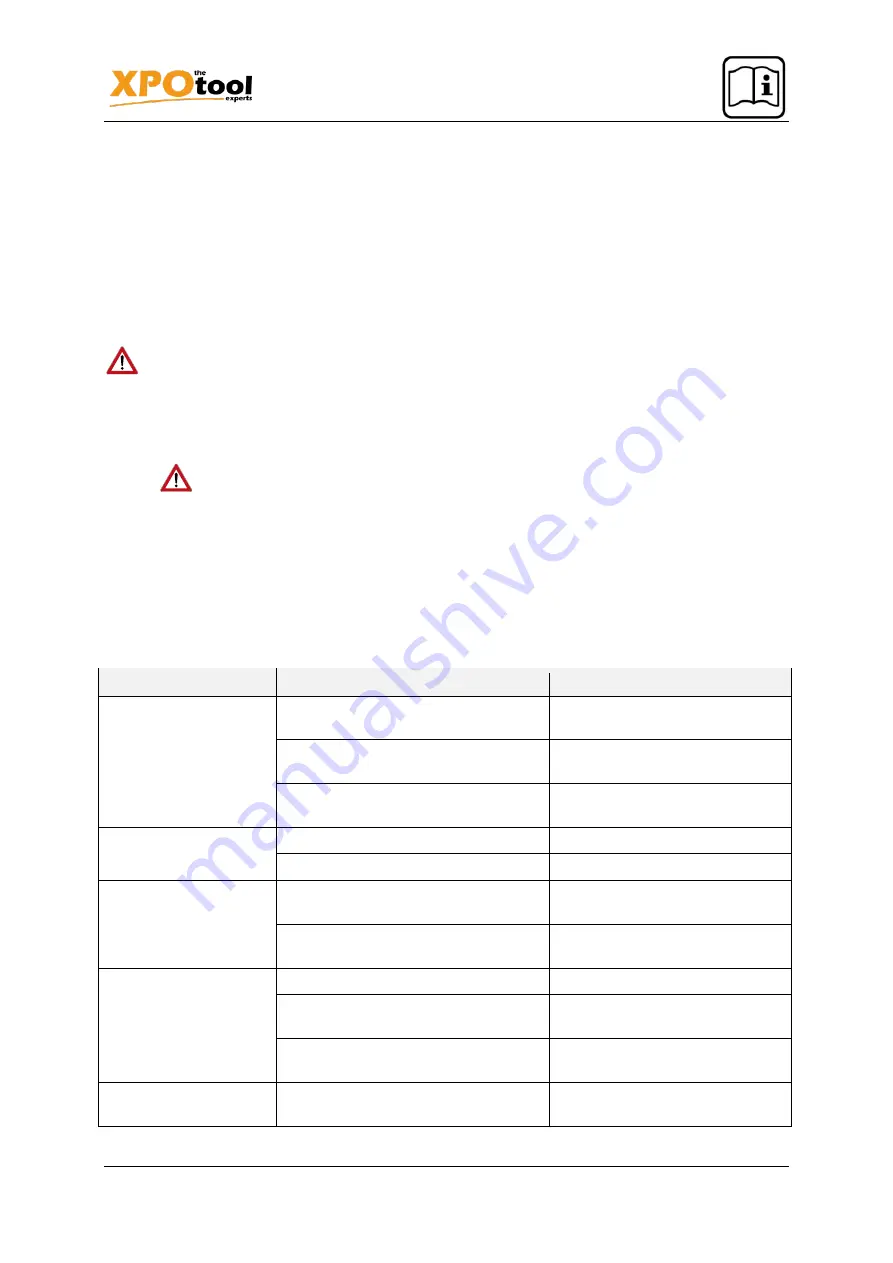

Troubleshooting

Problem

Cause

Solution

Pool water not sufficiently

cleaned

1. Pool chemicals not adequate to inhibit

algae growth.

1. Adapt chemical administration or

consult expert.

2. Wrong quantity or size of sand

2. Check sand depth and size or

contact expert.

3. Wrong flow rate

3. Run system for longer time or

consult expert.

Untight control valve

1. Control valve between two functions

1. Set control valve properly.

2. Gasket broken

2. Replace gasket.

Running motor, though

absence of water flow

through pump

1. Air entering the system

1. Check all hose/pipe connection

and make sure that the lid is tight.

2. Too high a suction height, wrong in-

stallation place

2. Move device/pump to a lower

place.

Sand flowing in the pool

1. Too small sand size

1. Use type-20 sand.

2. Sand level too high

2. Reduce sand level to two thirds

of the filter tank height.

3. Broken underdrain assembly

3. Replace damaged or broken as-

sembly.

Rise of filter pressure

1. Insufficient backwashing

1. Perform backwashing until water

coming out is clean.