• If metal switch boxes are used, earthing

regulations must be followed.

• The cross-sectional area of the supply cord

used should be ranged from 1-1.5mm².

• SSGX150S / SSGX150R / SSGX150PS /

SSGX150PR – 2 core.

1. Check that the electrical rating shown

inside the back-plate matches your

mains supply.

2. Check there are no buried pipes or cables

e.g. electricity, gas, water behind the switch

location (in the wall or above the ceiling). If

in doubt, seek professional advice.

3. Isolate the mains supply.

4. Lay in the cable from the isolating switch to the

fan location via the on/off switch (if required).

5. Lay in the cable from the isolating switch to

the point of connection to the mains supply.

Warning: Do not make any

connections to the electrical

supply at this stage.

6. Install the isolating switch and on/off switch

(if required).

7. Make all connections within the isolating

switch and the on/off switch (if required).

Wet Rooms: On/Off switch must

be situated so that it cannot be

touched by persons making use of

the bath or shower.

For Australia Only – SSGX150S / SSGX150R

/ SSGX150PS / SSGX150PR

Connection to the supply can be made by a

flexible 2-core cable complete with 3 pin plug

for insertion into an approved 10A GPO or

directly wired through an approved 10A wall

mounted surface switch with at least 3mm

clearance between contacts.

Preparing the Fan for installation.

1. Ensure external window clamps are

retracted into window duct before

installation.

2. Remove remaining backing paper from

gasket (See Figure A) and install window

duct into window, ensure level line is

horizontal.

3. Gently tighten the three clamp screws to

secure duct into window. (See Figure B)

4. Route power cable via cutout into window

duct. Ensure power cable remains near

edge of duct.

If working above ground floor

level, safety precautions must

be observed.

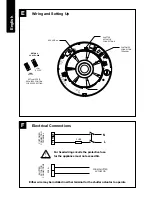

Fan installation

1. Carefully insert the fan into the window duct.

2. Feed the mains cable and shutter actuator

cable through the cable entry hole in the

back plate to the terminals. (See Figure E)

3. Fasten the back-plate to the window duct

using fasteners supplied. (See Figure C)

4. Do not over tighten screws.

Electrical connections.

1. Make sure the mains supply is isolated.

Switch off the mains electrical supply and

remove fuses.

2. Feed the cables to the appropriate terminal

block. Wire the fan as shown in Figure F .

3. Connect the cable from the isolating switch

to the electrical supply wiring.

Fan Settings

SPEED SETTING

The fans are factory set to low speed, but have

two speed settings for different applications.

Select either high or low speed by connecting

the jumper between the centre and high or low

speed pin on the jumper (see Figure E)

Using the fan

SSGX150S / SSGX150R Only

• Operate the fan using the on/off switch (not

supplied). Repeat to switch off.

SSGX150PS / SSGX150PR Only

• Operate the fan by pulling and releasing the

cord. Repeat to switch off.

Note –

The shutters are operated by a silent

thermo actuator which has a time delay on

opening (30-50 secs) and closing (3 mins).

All Fans

Re-fit the front grille assembly by hooking in

the top first, and then swing the cover down to

clip into place.

Cleaning

(recommended once a month)

1. Before cleaning, isolate the fan completely

from the mains supply.

EnglishEnglish