- 8 -

THIS HOOD IS DESIGNED TO USE A 6” ROUND DUCT -

IT MAY BE TRANSITIONED TO A 3-1/4” X 10” RECTANGULAR DUCT

NEVER REDUCE DUCT SIZE. UNDERSIZED DUCTING SEVERELY RESTRICTS AIR

FLOW AND HARMS PERFORMANCE.

(Example: the area of a 6” Duct is more than TWICE that of a 4” Duct)

KEEP DUCT RUNS AS SHORT AND STRAIGHT AS POSSIBLE.

AVOID USING FLEXIBLE METAL DUCTING IF RUN IS LONGER THAN 6’.

NEVER USE PLASTIC DUCTING.

USE SMOOTH BORE METAL DUCTING.

MINIMIZE THE NUMBER OF FITTINGS (see chart).

WHEN YOU MUST USE FITTINGS, TRY TO SEPARATE THEM WITH SECTIONS OF

3’ OR MORE OF STRAIGHT DUCT.

ALWAYS FOLLOW THE MANUFACTURER’S GUIDELINES FOR THE COOKING

EQUIPMENT YOU ARE VENTING.

IF MAKE UP AIR CONTROL DAMPERS ARE REQUIRED, POSITION THE SENSOR

IN A STRAIGHT RUN OF DUCT IDEALLY WITH 3’ OF STRAIGHT DUCT BETWEEN

EACH SIDE OF THE SENSOR AND A DUCT FITTING. REMEMBER TO INCLUDE

POWER AND CONTROL WIRING FOR THIS IN YOUR PLANS.

ADHERE TO ALL LOCAL BUILDING CODES AND ORDINANCES.

USE THE WORKSHEET THAT FOLLOWS TO HELP CALCULATE THE

TOTAL EQUIVILENT FEET

OF YOUR DUCT RUN.

TOTAL EQUIVILENT FEET SHOULD BE LESS THAN 100’.

a few simple rules to plan your

ductwork

Summary of Contents for XOCYL

Page 2: ......

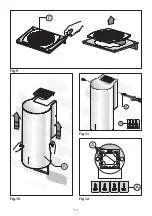

Page 15: ... 15 Fig 3 Fig 4 Fig 5 ...

Page 16: ... 16 Fig 6 Fig 7 Fig 8 ...

Page 17: ... 17 Fig 9 Fig 11 Fig 12 Fig 10 ...

Page 23: ... 23 1 2 5 6 e e ...

Page 41: ... 41 Fig 3 Fig 4 Fig 5 ...

Page 42: ... 42 Fig 6 Fig 7 Fig 8 ...

Page 43: ... 43 Fig 9 Fig 11 Fig 12 Fig 10 ...

Page 49: ... 49 1 2 5 6 e e ...

Page 67: ... 67 Fig 3 Fig 4 Fig 5 ...

Page 68: ... 68 Fig 6 Fig 7 Fig 8 ...

Page 69: ... 69 Fig 11 Fig 12 Fig 10 Fig 9 ...

Page 75: ... 75 1 2 5 6 e e ...

Page 80: ...3011000130501 00 ...