3-3

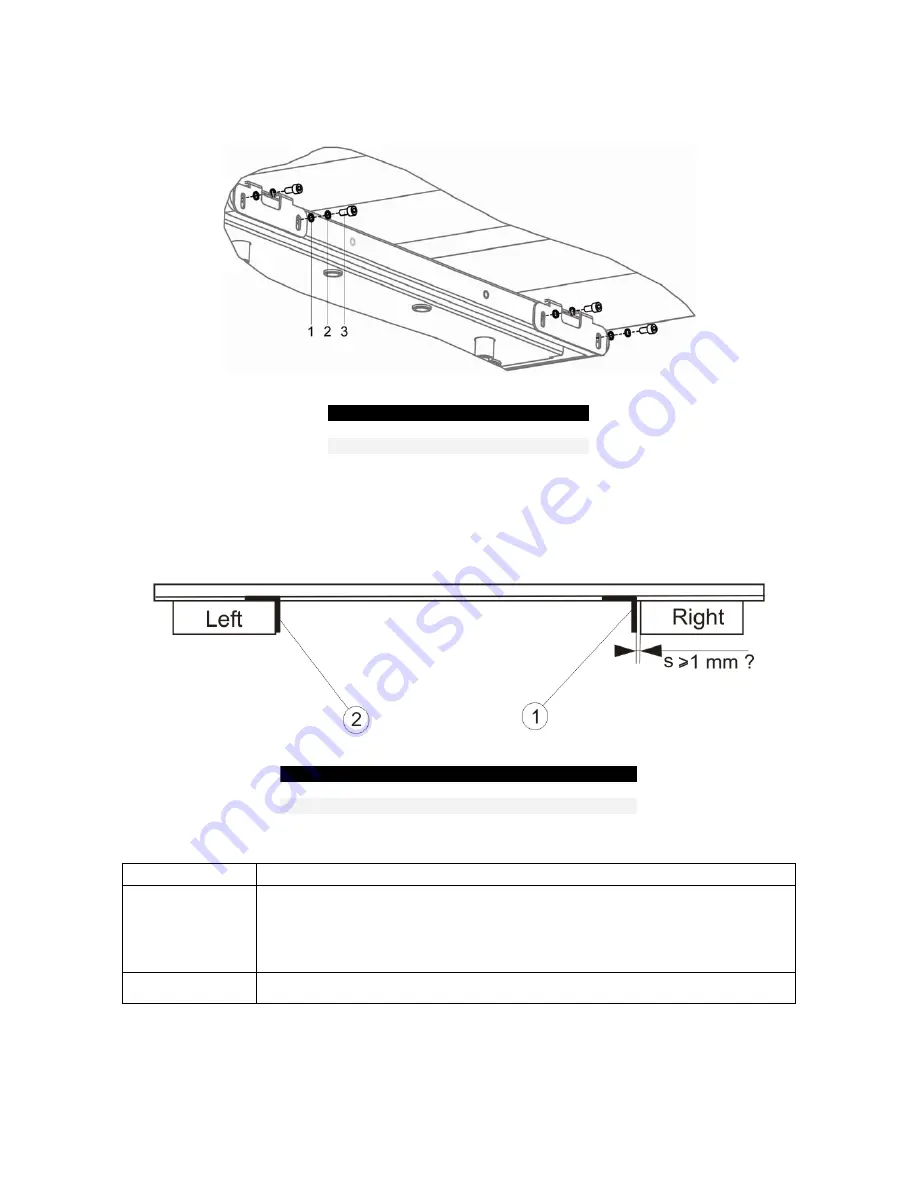

Step 2 :

Mount the left side of the bars with the mounting supports to the printer’s stand as indicated on

the image below.

No.

Description

1 Plain

washer

M6

2

Tooth lock washer M6

3

Hexagon bolt M6x12

Step 3 :

Check the gap (s) between the adjustable mounting support (1) on the right hand side and the

printer stand and perform the correct action. This has to be done for both roll unit bars. See

below.

No

Description

1 Adjustable

mounting

support

2

Left mounting support

3

Gap between support and printer foot

IF …

THEN …

s = 1 or s > 1 mm

•

loosen the 4 screws holding the support on the roll unit bar,

•

slide the support against the right side of the printer’s stand,

•

mount the support to the printer’s stand and fix the 4 screws holding the support

on the roll unit bar.

s < 1mm

•

mount the support to the printer’s stand without adjusting.

Summary of Contents for 82xx

Page 1: ...August 2007 701P47496 Xerox 82xx 83xx Wide Format Printer Unwinder Winder User Guide ...

Page 4: ...ii This page is intentionally left blank ...

Page 8: ...1 4 This page is intentionally left blank ...

Page 38: ...3 24 This page is intentionally left blank ...

Page 43: ......

Page 44: ......