Copyright © 2015 Ruckus Wireless, Inc.

Published May 2015

(OPTIONAL) MOUNTING INSTRUCTIONS

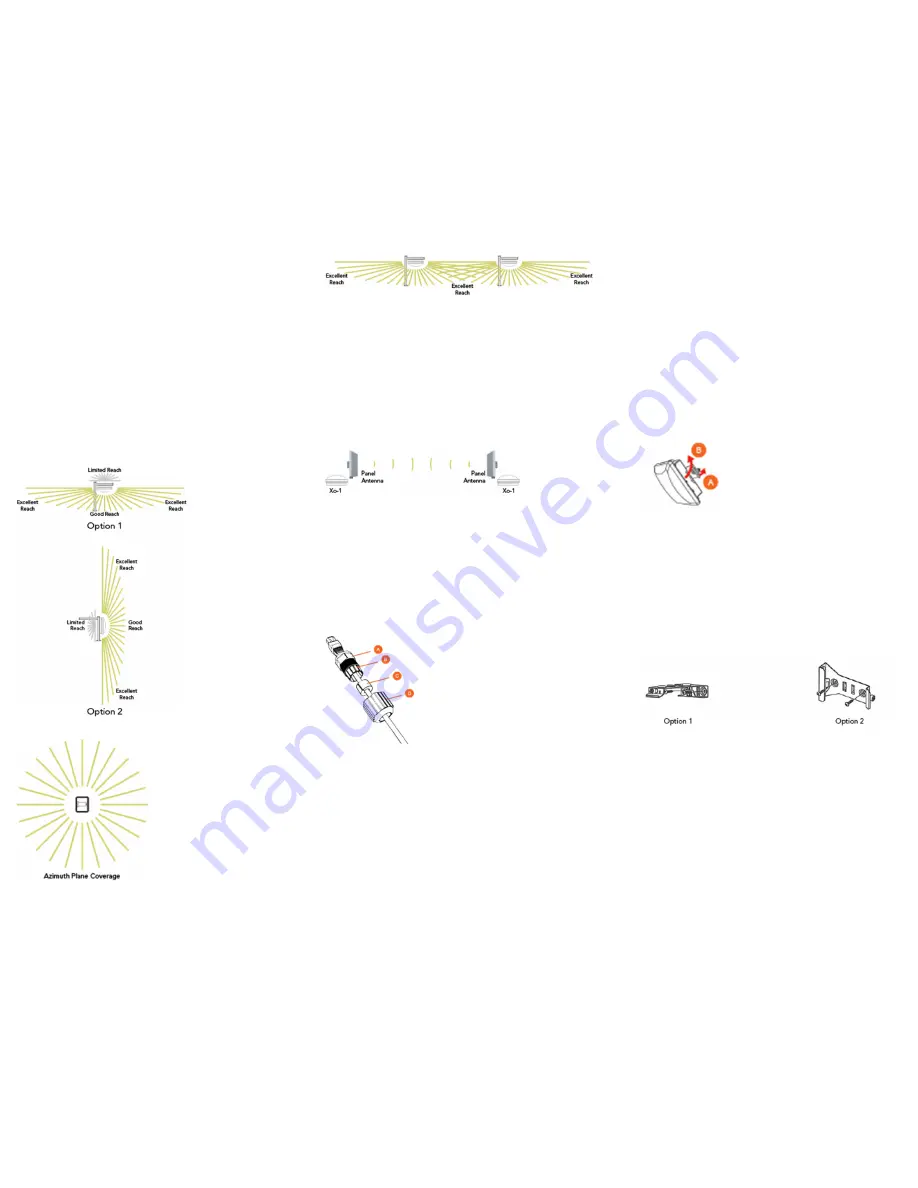

Xo-1 ANTENNA COVERAGE

The Xo-1 AP includes internal omni 5GHz and 2.4GHz

antennas, and has two female N-type connector for optional

customer-ordered external 5GHz antennas.

Internal Omni Antennas

When the internal antennas are used, the Xo-1 is best

deployed where lateral beamforming can provide the greatest

reach and throughput to a wide coverage area, or to provide

the greatest distance between APs in a connecting mesh

device. See Figure 1 for a typical side view coverage pattern,

see Figure 2 for a typical top view coverage pattern, and see

Figure 3 for a typical mesh coverage pattern.

Figure 1 – Typical AP internal omni coverage, side view

Figure 2 – Typical AP internal omni coverage, top view

Figure 3 – Typical AP internal-antenna mesh elevation plane

coverage, side view

External Customer-Supplied 5GHz Antennas

Instead of the internal omni 5GHz antennas, the Xo-1 can use

one or two external 5GHz antennas in point-to-point and other

specialized deployments for extended backhaul, higher

throughput, and/or larger or smaller beamwidths than those

provided by Ruckus Wireless AP internal antennas.

Figure 4 shows the Xo-1 used in a typical backhaul

deployment.

Figure 4 – Typical AP long-range point-to-point deployment

Step 1: Connecting and Sealing the RJ-45 Cable

The AP uses one RJ-45 cable for Ethernet backhaul and

Power over Ethernet (PoE). Connect and seal the cable using

the M25 data cable gland.

Feed the end of the RJ-45 cable through the sealing nut (D in

Figure 5), rubber sealing insert (C in Figure 5), clamping ring

assembly (B in Figure 5) and cable gland base (A in Figure 5).

Figure 5 – RJ-45 cable and cable gland assembly

Use a wide flat-blade screwdriver to remove the blanking cap

from the AP.

Connect the cable to the Ethernet port in the AP.

Tighten the cable gland base into the AP chassis to 7 N.m or

62 in-lbs.

Wrap the clamping ring assembly around the rubber sealing

insert. Make sure that the clamping ring assembly fully

encloses the rubber sealing insert.

Seat the clamping ring assembly and rubber sealing insert in

the cable gland base.

Tighten the sealing nut to 1.1 N.m or 10 in-lbs, or until the

rubber sealing insert is compressed.

Continue with Step 2a: Attaching the Mounting Bracket to a

Flat Surface or Step 2b: Attaching the Mounting Bracket to a

Metal Pole.

Step 2a: Attaching the Mounting Bracket to a Flat

Surface

The AP mounting bracket attaches to the AP using a captive

screw. Use a medium flat-blade or No. 2 Phillips screwdriver to

loosen the captive screw (A in Figure 6) and pull up on the end

of the bracket to remove the bracket from the AP (B in Figure

6).

Figure 6 – Removing the mounting bracket

Using either of the two options shown in Figure 7, hold the

mounting bracket at the location on the mounting surface

where you want to mount the AP. Use the holes on the

mounting bracket as a template to mark the locations of the

mounting holes.

NOTE:

The mounting bracket can be mounted to a vertical or

horizontal surface to support the AP in the required orientation.

Figure 7 – Mounting bracket on a flat surface

Remove the mounting bracket from the mounting surface.

Drill holes required for the customer-supplied mounting

hardware.

Attach the mounting bracket to the flat surface using the

mounting hardware.

Using the mounting hardware instructions, tighten the hardware

to secure the mounting bracket.

Continue with Step 3: Mounting the AP.