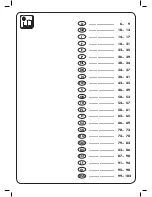

11

Product features

Prior to using this product, the user must become familiar

with all features and safety instructions.

Overview Fig. I

1

Scale

2

Auxiliary handle

3

Hex socket head screw

4

Star-shaped knob

5

Extraction feature

6

Light emitting diode

7

Hex socket head screw

8

Triangular marking

9

Guard

10

Guide shoe

11

Clamping nut

12

Locking knob

13

Slider switch

14

Hex bolt

15

Collar

16

Spacer rings

Product specifications

Art.

0702 414 X

Cutting discs - Ø

125 mm

Cutting disc bore - Ø

22.2 mm

Possible channel widths

10, 17, 23,

30 mm

Cutting depth

0 - 30 mm

Rated power consumption

1400 W

Output power

750 W

No-load speed

8200 rpm

Speed at rated load

8200 rpm

Typical effective acceleration in the

hand-arm area *

4 m/s²

A-weighted sound pressure level *

92 dBA

A-weighted sound power level *

103 dBA

Weight

3.9 kg

*) Values determined in accordance with EN 60745

Correct use

The product is only intended for cutting or making slots

in predominantly mineral-based materials (without the

use of water), e.g. steel reinforced concrete, masonry

and road surfaces.

The user is liable for damage caused by incorrect use.

If you have any queries on the product and its use, in

Germany our product and application consultancy

service will be pleased to be of assistance, tel.:0180-60

65 69 (14 cent/min).

Placing in operation

q

Prior to placing the product in operation, check

whether the mains voltage and mains frequency

stated on the type plate match your mains data.

Mains connection

The product has electronic starting current limiting. It is

sufficient if the sockets to which the product is connected

are protected with a type H circuit breaker or a fast-

blow fuse.

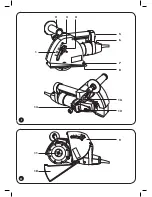

Preparing product for fitting the diamond

cutting discs (Fig. I)

·

Switch off product and isolate from the power

supply.

·

Unscrew hex socket head bolt

3

.

·

Slightly undo hex socket head bolt

7

.

·

Position guard

9

and the guide shoe

10

such that

you have clear access to the drive shaft on the

product for fastening the diamond cutting discs

(

Fig. II

).

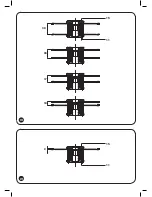

Fitting two diamond cutting discs (for cutting a

channel, Fig. III)

·

Fit collar

15

in the correct position on the drive

shaft (shoulder to the outside) and turn until it is

locked.

·

Fit first diamond cutting disc to the collar

15

. During

this process it is imperative you pay attention to

the

direction of rotation information

on the

diamond cutting disc and the product

!

·

Fit to the clamping nut

11

, the second diamond

cutting disc and the spacers to suit the width of

the channel. During this process it is imperative

you pay attention to the

direction of rotation

information

on the diamond cutting disc and the

product

!

·

Fit clamping nut

11

with the diamond cutting disc

and the spacers to the drive shaft on the product.

During this process tighten the clamping nut

11

by

turning it clockwise.

·

Press in locking knob

12

·

Slowly rotate front diamond cutting disc until the

locking knob

12

engages.

·

Tighten the clamping nut

11

using the flange

spanner supplied.

Never press in locking knob 12 with the

product running; also not when the

product is running down!

Summary of Contents for MSF 30

Page 3: ......

Page 4: ...6 11 12 14 7 8 5 9 10 0 10 20 0 1 0 2 0 3 0 13 1 2 3 4 I II...

Page 5: ...IV III 30 23 17 10 2 15 11 15 11...

Page 50: ...50 GR q q 2 q 9 q q q 15 q q q 30 q o q o o q q W rth...

Page 83: ...83 BG q q 2 q 9 q q q 15 q q q 30 q o q q q q q W rth...

Page 99: ...99 RUS q q 2 q 9 q q q 15 q q q 30 q o q o o q q W rth...