Installation, Oper ation & M aintenance M anual

TR-C Series Centrifugal Pump

13

TR-C-

M02

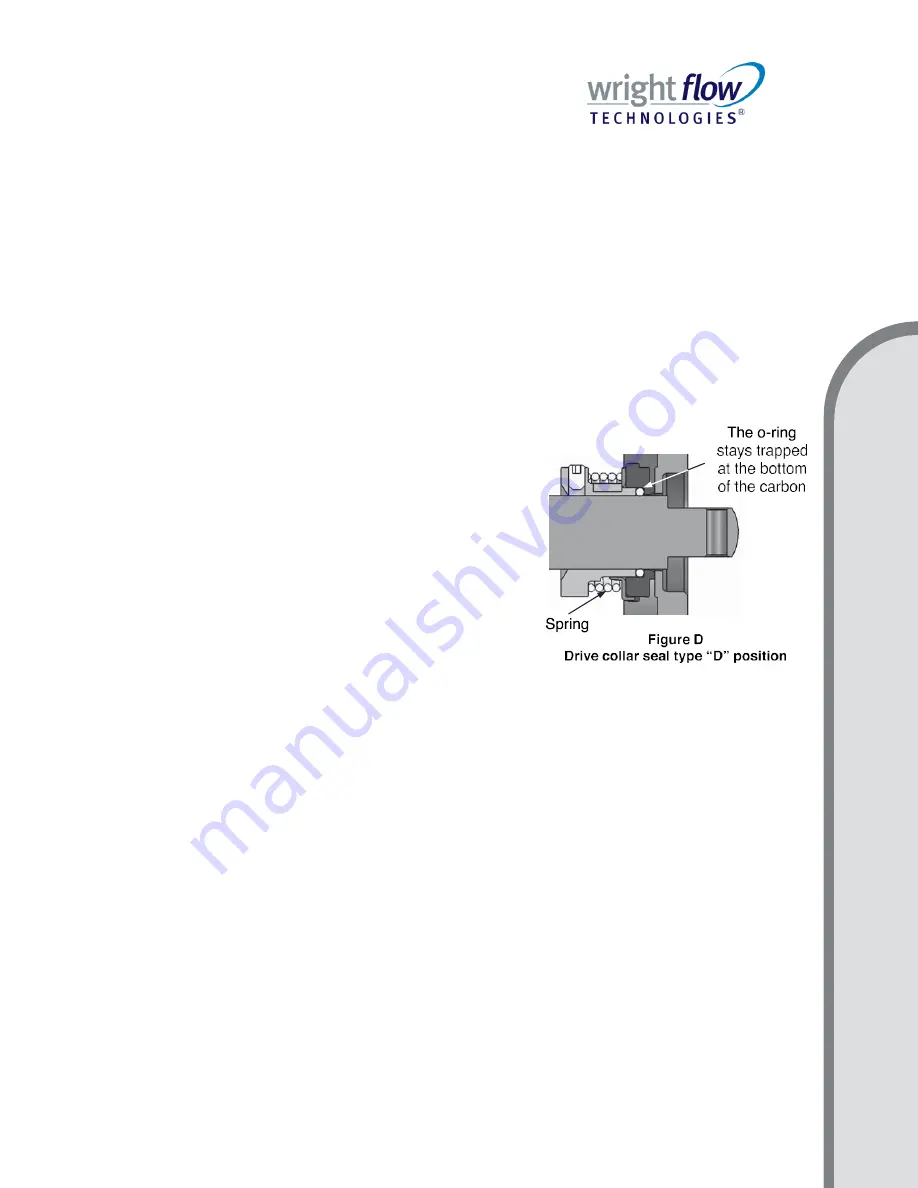

The seal will provide a resistance when it slides on, so apply pressure until it has gone onto

the stub shaft completely. The position of the drive collar against the o-ring and carbon is

critical to prevent leaks. Now, assemble the

“D” seal backplate (

11

) and fix it with the backplate

pins. Push the carbon back with the backplate.

Once the backplate has been placed it is necessary to tighten the “D” seal collar set screws

(

80L

). To do this, you must exert a pressure on the drive collar towards the backplate, so

that the pin of the drive collar remains aligned with the slot in the cup.

Tighten the set screws once the drive collar has reached its closest point to the o-ring and

carbon. The drive collar should stay in its place against the o-ring

– against the back – within

the limits of the carbon, as shown in

Figure D.

The spring does not

compress entirely.

When all parts are in their correct positions, the stub shaft

should be able to rotate freely when turned by hand. If it is

necessary to use excessive force to turn the stub shaft, check

to be sure that the components of the seal have been properly

installed and that the drive collar is properly positioned.

The “F” seal is the “D” seal with a water-cascade assembly.

The water-cascade assembly (

132

) should be installed on

the adapter (

71

), so that the leak falls upon the seal seat of

the carbon, lubricating the seal against the backplate.

IMPORTANT:

It is necessary to disassemble some of the

pump parts for cleaning and

sterilizing. For those Wright Flow

products equipped with “D” seals, if a CIP (Clean-in-Place)

installation is used, disassembly is not necessary. Do not lubricate the seal with grease or oil,

the faces of the seals are lubricated by the fluid that is being pumped.

CLAMPED-IN SEAT SEAL TY

PE “DG”.

This seal type consists of two parts: one

stationary, and one rotating. The rotating part is the

“D” seal assembly. For that reason, it is

highly recommended that you read the directions above for assembling the

“D” seal before

continuing. The stationary part consists of the following elements:

“DG” seal seat (

80N

), PTFE

gasket (

80P

), PTFE gasket (

80R

), “DG” gland ring (

17J

), lock washers (

17M

), bolts/screws

gland ring (

17K

),

and “DG” seal backplate (

11H

).

IMPORTANT:

Incorrect spacing between the impeller and backplate can result in dangerous

contact between the impeller and the face of the stationary seal. That contact may wear down

the impeller and the seat of the gland ring. A visual inspection following the installation of the

impeller is recommended to check the spacing of the impeller and seal.

Take

the “DG” backplate (

11H

), turn it around and place the PTFE gasket (

80R

) against the

seal face. Next, install the seal seat (

80N

)

– which is reversible – followed by the PTFE gasket

(

80P

) and finally the gland ring (

17J

). In the seal type

“DG”, the seal seat (

80N

) is enclosed by

the gland ring, which could be made of either silicone, tungsten, or ceramic

A

SS

EM

B

LY