Pre-Installation

Worcester Commercial Boiler Series – 6720814332 (2019/04)

20

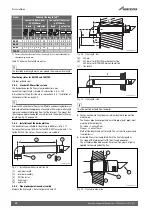

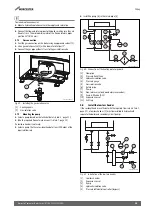

Table 11 Reduced flue lengths in metres

The total reduction length must never exceed the maximum flue length.

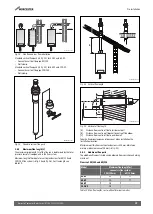

Weathering slates for 80/125 and 100/150

Flat roof, pitched roof.

3.8.4

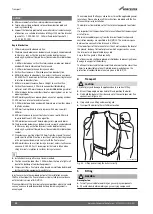

Standard 100 mm flue systems

The standard concentric flue system provides for a max.

horizontalstraight length (

table 10, subsection 3.8.3). Full

instructions for fitting this flue are in subsection 3.8.5: ” Installation of

the horizontal flue” on page 20.

Important: Any horizontal flue system fitted to a condensing boiler must

be declined towards the appliance at an angle of 53mm per metre length

to prevent condensate dripping from the flue terminal. This means that

the clearance above the appliance must factor in the horizontal flue run

length. See fig. 21 on page 18.

3.8.5

Installation of the horizontal flue

The standard flue is suitable for lengths up to 660mm (

For longer flue runs up to 20.0m for the 100/150 flue system and 7.7m

for the 80/125 flue system, flue extensions are available.

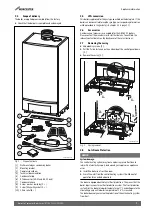

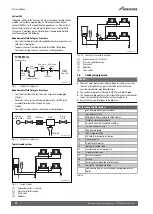

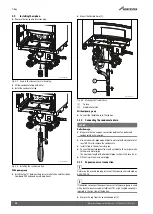

Fig. 27 Installation with horizontal flue kit

[1]

maximum length

[2]

terminal assembly

[3]

90° flue turret

[4]

finishing kit

[5]

outer wall

3.8.6

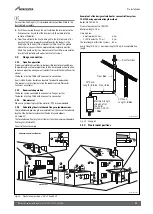

Flue pipe preparation and assembly

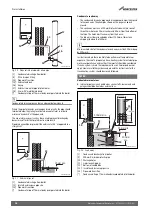

Measure the flue length L. Refer to figures 28 and 29.

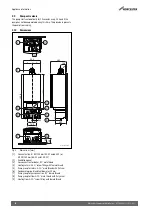

Fig. 28 Flue length - rear

[A]

152mm

[B]

337.5mm for Ø 80/125mm horizontal flue

339.5mm for Ø 100/150mm horizontal flue

[L]

flue length

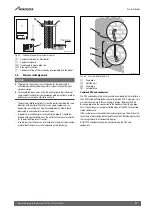

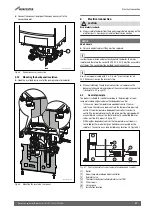

Fig. 29 Flue length - side

The flue must be inclined from the boiler.

▶ For connection into the elbow, a minimum length of pipe must be

maintained.

The flue gas pipe (inner pipe) and air intake pipe (outer pipe) must

maintain different lengths:

Air intake = L minus 50mm

Flue gas = L minus 70mm

Mark off the lengths and cut to length. The cuts must be square and

free from burrs.

▶ Assemble flue system completely. Push the flue fully together.

The slope of the terminal outlet [2] must face downwards.

The assembly will be made easier if a solvent free grease is lightly

applied to the male end of the flue.

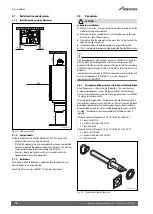

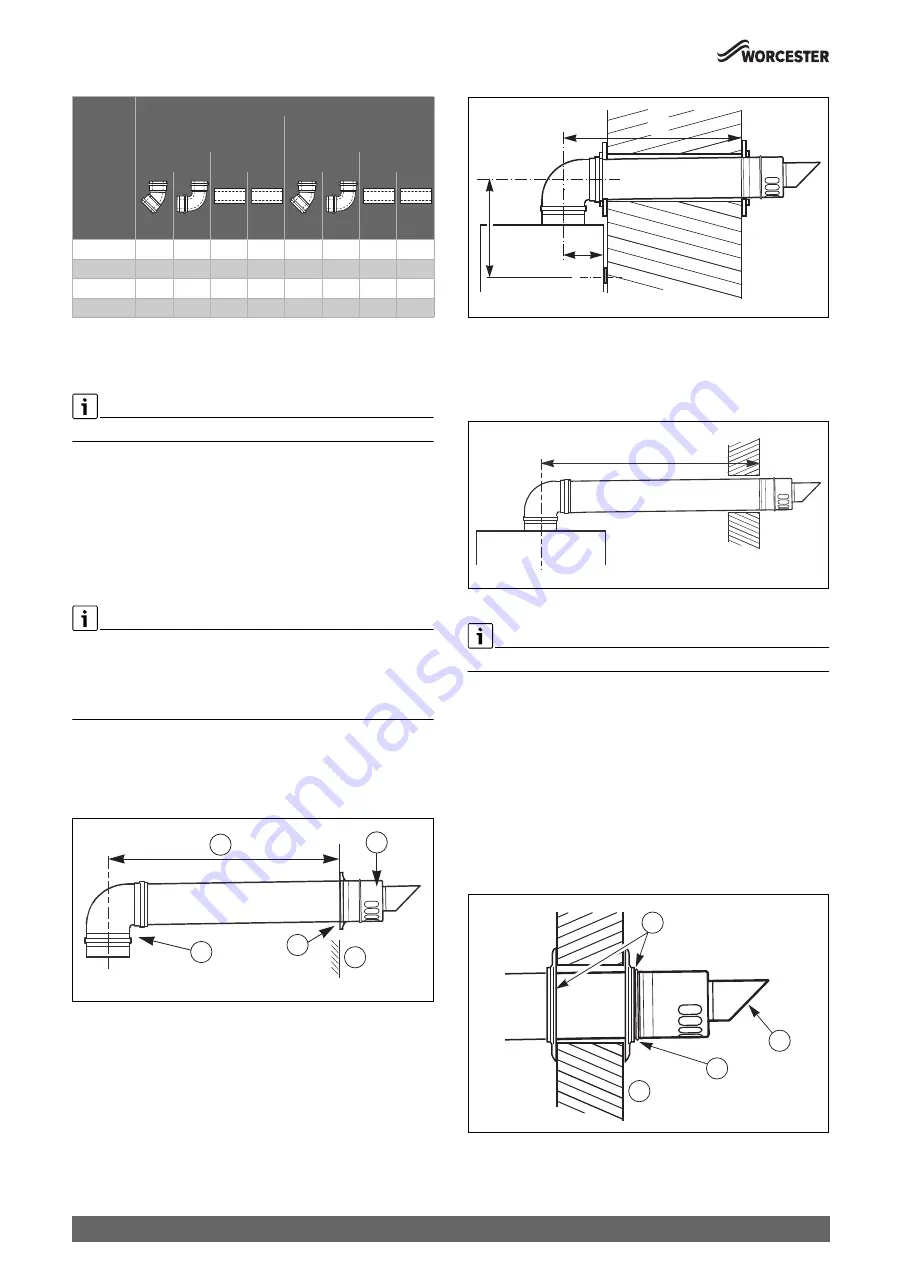

Fig. 30 Flue terminal position

Model

Reduced flue length [m]

1)

1) For every bend or extension the max. flue length (L) has to be reduced by the

corresponding length in m.

concentric flue system

100/150mm

concentric flue system

80/125mm

bend

extension

bend

extension

45°

90°

0.5m

1m

45°

90°

0.5m

1m

50-V2

1.2

2.1

0.5

1.0

0.9

1.9

0.5

1.0

65-V2

1.2

2.1

0.5

1.0

0.9

1.9

0.5

1.0

85-V2

1.2

2.1

0.5

1.0

-

-

-

-

100-V2

1.2

2.1

0.5

1.0

-

-

-

-

0010025999-001

5

4

3

2

1

0010026000-001

A

L

B

0010026001-001

L

0010026002-001

4

3

2

1