5

12

SPECIFICATIONS

Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2HP, 115VAC, 5A, 1720 RPM

Speeds (RPM) . . . . . . . . . . . . . . . . . . . . . . . . . .500, 840, 1240, 1800, 2630, 3975

Swing over bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10"

Swing over toolrest base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1/4"

Distance between centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17"

Inboard bed length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-5/8"

Bed gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1/4"

Spindle size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1" x 8TPI

Headstock taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#2 MT

Headstock through bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8"

Faceplate diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1/8"

Tailstock quill travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3/8"

Tailstock quill taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#2 MT

Tailstock through bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8"

Tool rest length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6"

Machine dimensions . . . . . . . . . . . . . . . . . . . . . . . .33-1/2"L x 9-1/2"W x 14-3/4"H

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87 lbs (39.5 kgs)

Shipping weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115 lbs (52.3 kgs)

Note: Specifications, while deemed accurate, are subject to change without notice.

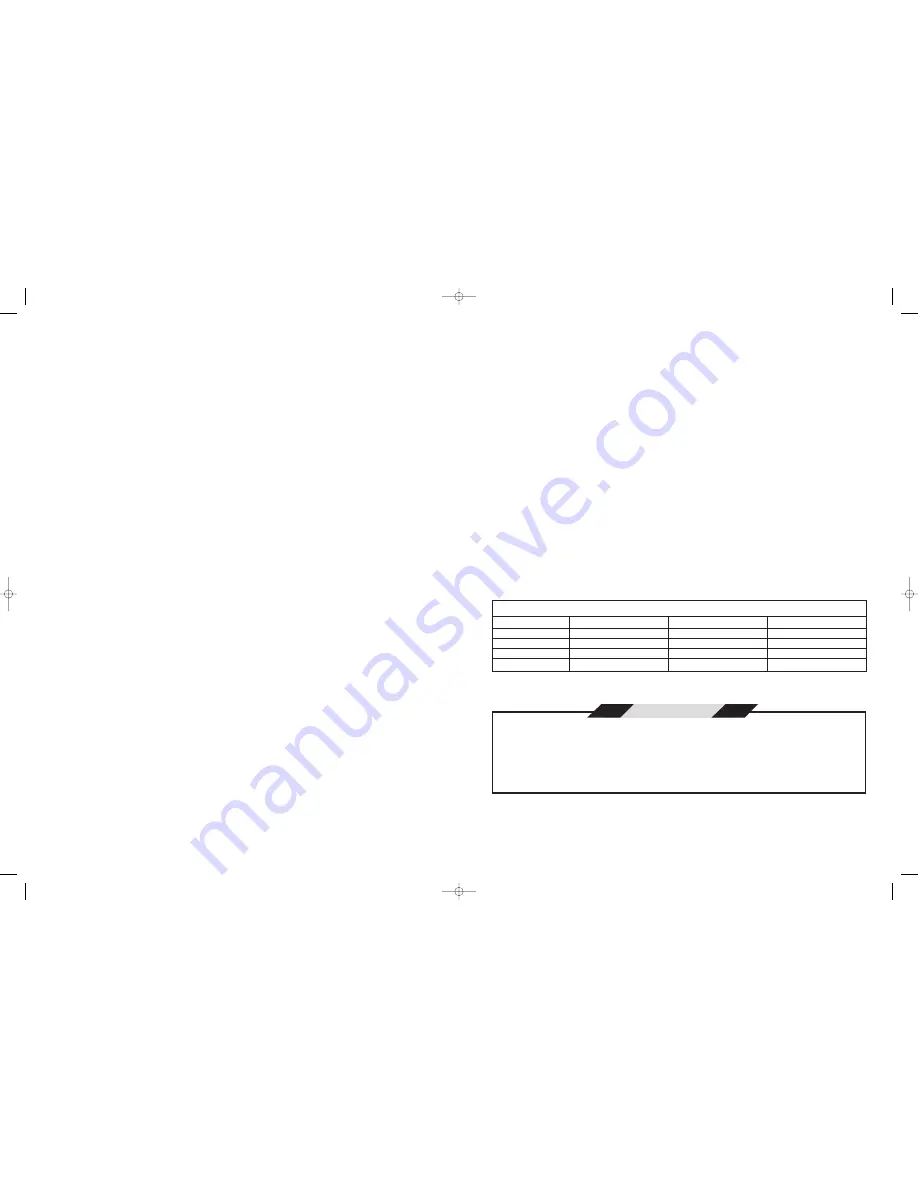

DIAMETER

ROUGHING

GENERAL

FINISHING

Under 1"

1800

2600

4000

1" to 3"

1200

1600

2600

3" to 6"

500

1200

1800

Over 6"

500

800

1200

SPEED RECOMMENDATIONS (RPM)

Some dusts created by woodworking activities may contain chemicals known to cause

cancer, birth defects, reproductive disease, respiratory disease and skin allergies.

Chemicals include: arsenic, chromium and formaldehyde from chemically treated

lumber and building materials; crystalline silica from masonry products; lead from

lead-based products; and quinones, alkaloids and glycosides from some exotic

hardwoods.

Warning

Preview

There are many different turning accessories used

for mounting wood on a lathe. This example covers

one procedure using a 3" faceplate and a 4-jawed

chuck with 1" x 8TPI spindle threads to fit this lathe.

Preparing the wood for turning

1- Wood selected for bowl turning can come from

many sources including trunks, branches, roots

and burls. Select a piece of fairly dry wood

about 5" in diameter and 3" deep.

2- Mark the center of the top of the bowl blank and

draw a circle with a compass the diameter of the

faceplate.

3- Center and screw the faceplate on the top of the

bowl and mount the turning blank on the inboard

spindle. The bottom of the bowl will be facing

outward.

Turning the bowl

1- With a 1/2" bowl gouge turned over on its side

and the flutes facing the direction of the cut, true

up the outside of the bowl at the speed

indicated on the Speed Chart.

2- Keep the bevel of the gouge running close to the

wood.

3- Remove the bulk of the waste wood from the

lower outside part of the bowl.

4- Define the outside shape of the bowl leaving

enough room on the bottom for a raised foot.

5- Turn a recess dovetail on the bottom of the bowl

to accept the internal chuck jaws.

6- Remove the bowl from the lathe and remove the

faceplate.

7- Put the chuck on the lathe and mount the

bottom of the bowl on the chuck.

8- Turn the inside of the bowl with a 1/2" bowl

gouge to a thickness of about 3/4". Start in the

middle of the bowl and turn away a small hollow.

9- Each successive cut should start further out

toward the rim and move down and into the

center of the bowl.

10- Continue in this manner until the bowl is

completely hollowed out with a wall thickness of

about 3/4".

11- Leave a raised center inside the bottom of the

bowl and cut a recess dovetail to accept internal

chuck jaws after seasoning.

12- Remove the bowl blank from the lathe and let it

dry. This may take several weeks or months

depending on how wet the wood is.

13- Once dried, remount the bowl using the dovetail

inside the bowl and true up the outside shape of

the bowl.

14- Turn a desired profile for the foot on the bottom

of the bowl and true up the bottom recess

dovetail.

15- Completely sand the outside of the bowl

including the foot and recess dovetail.

16- Remove the bowl from the lathe and remount

the bowl on the lathe using the bottom recess

dovetail.

17- Finish turning the inside of the bowl with long

shearing cuts from the rim to the bottom of the

bowl. As the wall thickness decreases use a

smaller 3/8" fingernail gouge for better control.

Keep the wall from vibrating by providing hand

support or using a bowl steady.

18- Completely sand the inside of the bowl. Finish

on or off the lathe as desired.

Bowl Turning

143-009 MidiLathe (16) 9/28/07 11:16 AM Page 5