Model W1784 (Mfg. Since 2/07)

-8-

DO NOT place your hands near the

staple point of entry. A staple can

deflect and tear through the surface

of the workpiece, puncturing your

hand or fingers.

NOTICE

DO NOT use the stapler to position

the flooring strip. Doing so will

damage the stapler and possibly the

flooring strip.

Note:

If you are using pre-finished

flooring material, test the stapler

on a sample strip. If the stapler base

plate is damaging or marring the

flooring surface, replace it with a

new one.

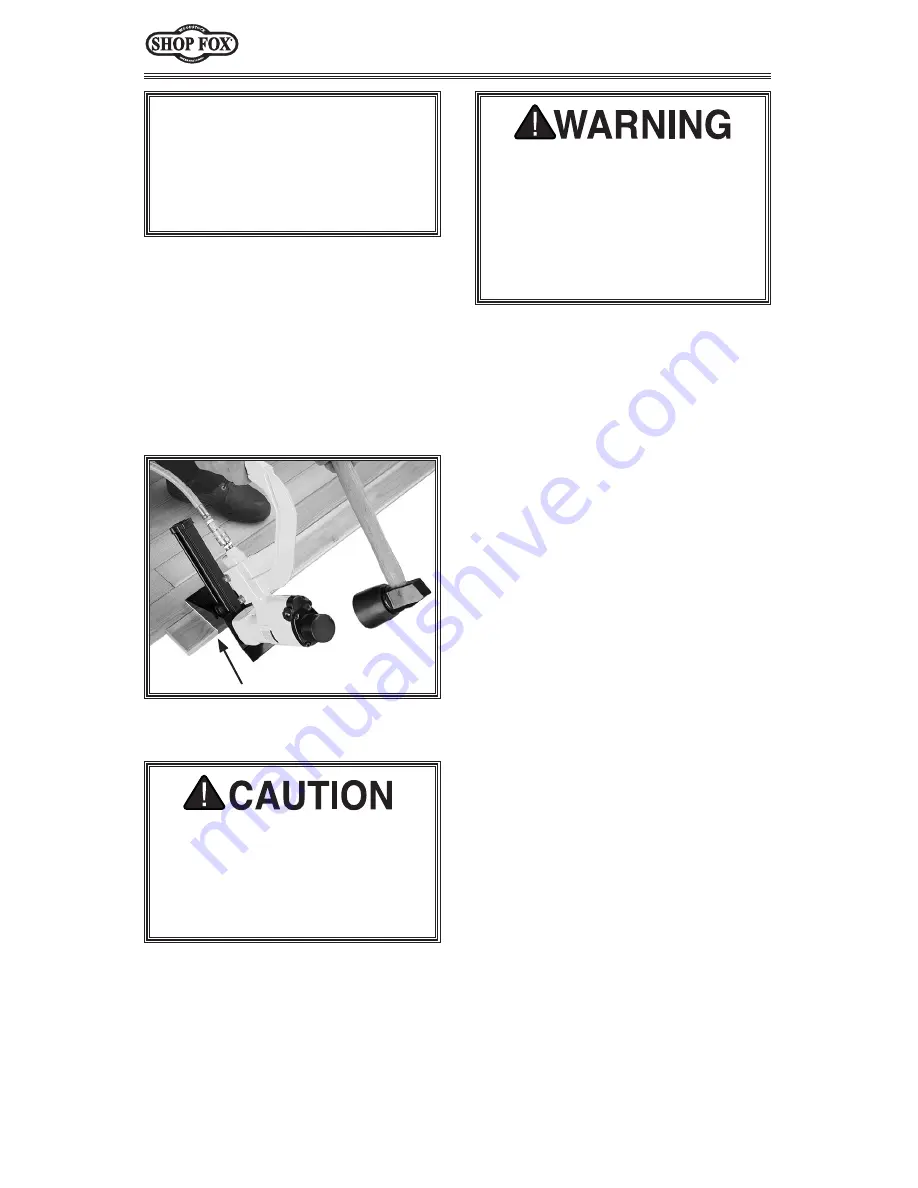

4.

Place the stapler on the flooring

strip, as shown in

Figure 3

.

5.

Make sure the cleat on the stapler

base plate is lined up with the edge

of the groove on the flooring strip.

6.

Using the

rubber

end of the included

hammer, hit the whack cap of the

stapler

ONCE

with a light to medium

force to shoot a staple into the wood.

Never hit the whack cap of the

stapler multiple times to drive the

staple into the wood. If necessary,

use a hammer to drive the staple in.

Failure to heed this warning could

cause a staple jam or a ricochet, and

serious personal injury.

7.

Check the staple for satisfactory

penetration.

— If the staple depth is satisfactory,

proceed with your project.

— If the staple depth is too shallow,

slightly increase the air pressure.

— If the staple depth is too deep,

slightly decrease the air pressure.

Note:

Staple penetration is not

always consistent due to variations in

the flooring material. If necessary,

use a hammer to finish seating the

staple.

Clearing Jammed

Staples

A jammed staple must be cleared before

using the stapler again.

To clear a jammed staple from the dis-

charge area, do these steps:

1.

DISCONNECT STAPLER FROM THE AIR

SUPPLY!

2.

Pull the magazine loader handle all

the way back and remove the staple

stick.

Figure 3.

Positioning and operating

stapler on flooring strip.

Summary of Contents for SHOP FOX W1784

Page 20: ......