Dealer Service

27

MAN0826 (8/31/2010)

DEALER SERVICE

The information in this section is written for dealer ser-

vice personnel. The repair described here requires

special skills and tools. If your shop is not properly

equipped or your mechanics are not properly trained in

this type of repair, you may be time and money ahead

to replace complete assemblies.

Before working underneath, read manual

instructions, securely block up, and check stability.

Secure blocking prevents equipment from drop-

ping due to hydraulic leak down, hydraulic system

failure, or mechanical component failure.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

BLOCKING METHOD

NOTE:

SEE BLOCKING METHOD, PG. 19

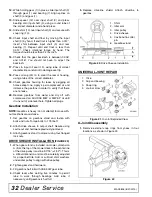

BLADE SPINDLE SERVICE

Spindle Repair

Spindle repair requires special skills and tools. If your

shop is not properly equipped or your mechanics are

not trained in this type of repair, you may be time and

money ahead to use a new spindle assembly.

For reference, the grease fitting is in the top of the spin-

dle shaft.

Permatex

®1

3D Aviation Form-A-Gasket or equivalent

is recommended as a sealant

Spindle Removal

(Figure 14)

1.

Remove blade from spindle.

2.

Remove belt from pulleys.

3.

Remove jam nut (1) and washer (3) from top of

spindle shaft.

4.

Disassemble split taper bushing (5) (located on top

of pulley) by removing the two bolts (2) and

washers (4).

5.

Insert bolts (2) into the threaded holes of bushing

flange.

6.

Tighten bolts alternately to remove split taper

bushing.

7.

Remove pulley (6).

8.

Remove bolts (19) that attach spindle to mower

frame and remove spindle.

9.

Remove grease fitting (21) from top of shaft.

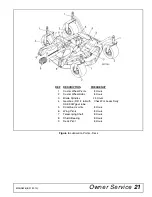

Figure 14

. Sheave and Blade Assembly

1. Permatex is a registered trademark of the Permatex

Corporation.

WARNING

CAUTION

1. Nut, jam 7/8 NF

2. Screw, HHCS 1/4 NC x 1 GR5

3. Washer, lock .929 x 1.66

4. Washer, lock 1/4

5. Bushing, H 1 straight bore w/key

6. Sheave, H 1 BK

19. Screw, HHCS 1/2 NF x 1-1/4 GR5

21. Grease fitting

Summary of Contents for Turf Batwing TBW144

Page 1: ...OPERATOR S MANUAL TURF BATWING MAN0826 Rev 11 15 2013 TBW144 TBW180 TBW204...

Page 39: ...Assembly 39 MAN0826 8 31 2010 NOTES...

Page 42: ...42 Parts MAN0826 8 31 2010 TBW144 TBW180 TBW204 MAIN FRAME ASSEMBLY Rev 11 15 2013...

Page 44: ...44 Parts MAN0826 8 31 2010 TBW144 TBW180 TBW204 TRAILER ASSEMBLY Rev 11 15 2013...

Page 50: ...50 Parts MAN0826 8 31 2010 CASTER ARM WHEEL ASSEMBLY...

Page 56: ...56 Parts MAN0826 8 31 2010 TBW144 TBW180 TBW204 REAR WING DECK DRIVES...