7.5 REPLACEMENT AND DISPOSAL

Should replacement become necessary, the machine

parts must be replaced with original components in order

to guarantee their efficiency.

The replaced parts must be disposed of in compliance

with the laws in force in the country of use.

Component replacement requires specific training and

technical skills; for this reason, the above interventions

must be carried out by qualified personnel to prevent

damage to the machine and risks to the safety of persons.

-18-

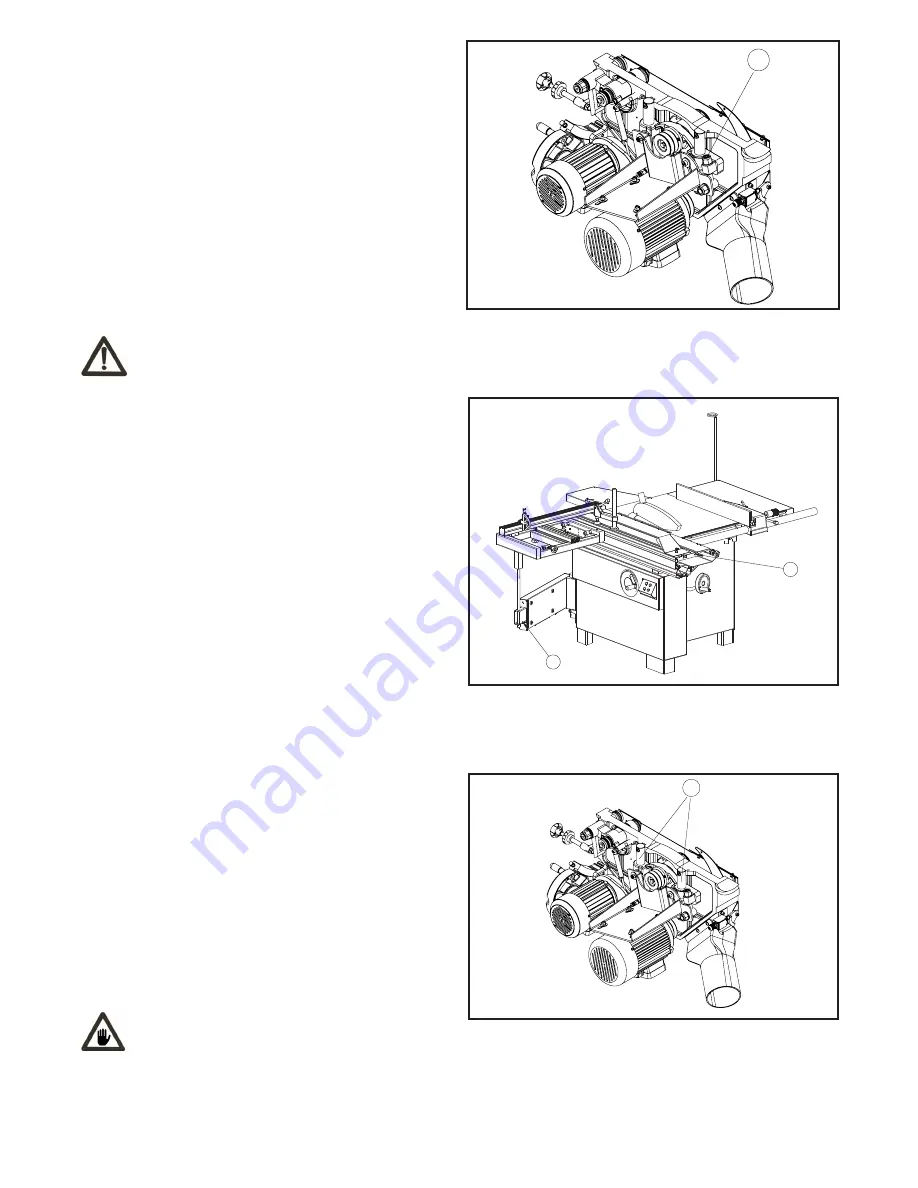

Fig.7.3

7.4 GENERAL LUBRICATION

- Weekly clean and lubricate all the mobile couplings of

the machine A with a thin film of oil and grease.

- Protect all belts and pulleys to avoid contamination with

oil.

Fig.7.4

7.3 OVERALL CLEANING

Please DO NOT to try removing chips while the saw

blade is running.

WARNING

After each working cycle, thoroughly clean the machine

and all of its parts, vacuum the shavings and dust and

remove any resin residues.

Use compressed air only when strictly necessary, using

protective glasses and a mask.

In particular, clean the following parts:

- the sliding table rail A;

- the sliding support extension B;

CAUTION

- In case of mechanical or functional faults in the machine, including guards or tools, please call the local authorized

agent for technical assistance and maintenance.

- Any maintenance must be only done when the machine is isolated from all energy sources (plug out).

A

A

B

Fig.7.2

A

7.2

REPLACE

BELT

Tools Required for Assembly:

- 4mm allen wrench

- 6mm allen wrench

-Open right side plate with 4mm allen wrench, then rotate

the screw rod at A of figure 7.2 with 6mm allen wrench.

-When rotating the wrench clockwise, belt becomes loose;

when rotating the wrench anticlockwise, belt becomes

tight.