Cascade Gas-Fired Rotisserie & Charbroiler

Installation and Operation Manual

7

An ongoing program of product improvement may require us to change

specifications without notice.

WS-GFR-MB, Revised November 2014.

Doc no: M0050.01

or visit

woodstone-corp.com

wood stone corporation

1801 w. bakerview rd.

bellingham, wa 98226 usa

tf. 800.988.8103

t. 360.650.1111

f. 360.650.1166

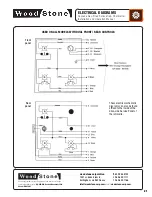

CLEARANCES & VENTING

Top Service Panel

Bottom Service Panel

Gas

Charbroiler

Radiant Flame Burner (SV-2)

Infrared Burner (SV-1)

INSTALLATION CLEARANCES

SIDES AND TOP

• Minimum clearance from sides and top of rotisserie to

combustible

construction is 36"�

• Minimum clearance from sides and top of rotisserie to

non-combustible

construction is 0"�

FLOOR

• The unit is suitable for installation on combustible floors�

WARNING:

Do not pack required air spaces with insulation or other material. Do not obstruct the flow of combustion and

ventilation air.

VENTING

The Wood Stone Cascade Gas-fired Rotisserie must be vented using a Listed Type 1 exhaust hood or one constructed in accordance

with the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA 96, and all relevant local and

national codes, and in a manner acceptable to the authority having jurisdiction� It is never appropriate to use “B vent” in any part of

an exhaust system connected to this rotisserie�

VERY IMPORTANT! WOOD STONE RECOMMENDS THAT YOU SUBMIT VENTING PLANS TO

LOCAL CODE AUTHORITIES BEFORE PROCEEDING WITH INSTALLATION.

SERVICE PANEL ACCESS

Drive-side Service Panels will need to be removed during the assembly of, and utility connection to, the rotisserie�

All obstructions 5' from drive side only of unit must be removable for service access�

All obstructions 5' from

drive side only of unit

must be removable for

service access.

CLEARANCES