PROCEDURE

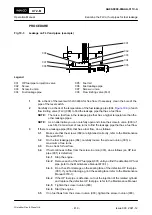

Fig 10-3

Leakage on FLV and pipes (example)

001

002

003

004

006

005

007

008

Legend

001

HP fuel pipe to injection valve

005

Fuel rail

002

Screw

006

Fuel leakage pipe

003

Screw-in union

007

Screw-in union

004

Fuel leakage pipe

008

Flow limiting valve (FLV)

1

Do a check of the level switch LS3446A for free flow. If necessary, clean the bore of the

pipe of the level switch.

2

Carefully do a check of the temperature of the fuel leakage pipe (004,

) of each

flow limiting valve (FLV) (008) to find the leakage pipe that has a fuel flow.

NOTE:

There is a fuel flow in the leakage pipe that has a higher temperature than the

other leakage pipes.

NOTE:

As an alternative you can carefully open and close the screw-in union (003) of

each FLV a maximum of two turns to find the leakage pipe that has a fuel flow.

3

If there is a leakage pipe (004) that has a fuel flow, do as follows:

3.1

Make sure that the screws (002) are tightened correctly, refer to the Maintenance

Manual 8733-1.

3.2

On the fuel leakage pipe (004), carefully loosen the screw-in union (003) a

maximum of two turns.

3.3

Do a check for fuel flow.

3.4

If fuel continues to flow from the screw-in union (003), do as follows (an HP fuel

pipe (001) is defective):

3.4.1

Stop the engine.

3.4.2

Remove each of the HP fuel pipes (001) until you find the defective HP fuel

pipe (refer to the Maintenance Manual 8733-1).

3.4.3

Do a check for damage on the sealing face of the defective HP fuel pipe

(001). If you find damage, grind the sealing face (refer to the Maintenance

Manual 8733-1).

3.4.4

If the HP fuel pipe is defective, cut out the injection of the related cylinder

and replace the defective HP fuel pipe, refer to the Maintenance Manual.

3.4.5

Tighten the screw-in union (003).

3.4.6

Start the engine.

3.5

If no fuel flows from the screw-in union (003), tighten the screw-in union (003).

X72-B

AA00-0000-00AAA-311C-A

Operation Manual

Examine the FLV or fuel pipes for fuel leakage

Winterthur Gas & Diesel Ltd.

- 419 -

Issue 003 2021-12