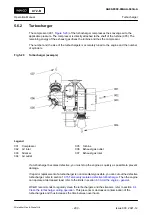

5.6.3

Auxiliary blower

The auxiliary blowers supply air from the engine room through the duct into the scavenge air

receiver during the engine start and operation at low load. The flaps prevent the back flow of air

to the scavenge air receiver during usual operation of the turbochargers and during engine stop.

The electric motor (004,

) operates the auxiliary blower (003).

The pressure relief valve is installed to protect the scavenge air receiver, when pressure is more

than set limit.

The auxiliary blowers are installed on the scavenge air receiver, refer to section

.

Fig 5-30

Auxiliary blower

001

002

004

003

Legend

001

Air outlet

003

Auxiliary Blower

002

Air inlet

004

Electric motor

During the engine start operation, the auxiliary blowers start one by one at two or three seconds

interval, to avoid electric overload.

Minimum one auxiliary blower is necessary to start the engine.

NOTE:

During emergency operation, the auxiliary blowers can be manually controlled when all

the scavenge air pressure transmitters are faulty.

During the engine operation, when the turbochargers supply sufficient air pressure in the scavenge

air receiver, the auxiliary blowers stop automatically by tunings depended setup and starts again

if required, (Delta bar).

The auxiliary blower switch box (refer to section

5.6.4 Auxiliary blower switch box

) is the interface

between the operator and auxiliary blower and gives data about the condition of the auxiliary

blowers.

X72-B

AA00-6545-00AAA-043A-A

Operation Manual

Auxiliary blower

Winterthur Gas & Diesel Ltd.

- 202 -

Issue 003 2021-12