TRIDENT

COMPACT 17"

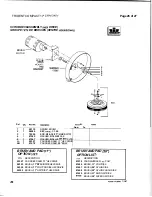

PROBLEM

No

power to

machine

Electrical shock

motor speed

POSSIBLE

CAUSE

Dead electrical circuit

Power switch failure

Faulty power cord

Equipment not grounding

Receptacle not grounded

Internal wiring problem

Worn motor brushes

varies or doesn't run

Motor worn out

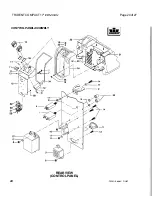

Loss of

Vacuum

Faulty switch

Loose recovery tank lid

Crack in recovery tank lid

or poor joint

Lint or dirt clogging

vacuum screen

Loosecuffsonvacuum

hose

motor seals leaking

Floor

tool

chamber

clogged

motor, hose, or

dome gasket

Page 11 of 27

TROUBLE SHOOTING GUIDE

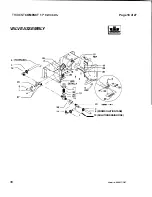

Solution not

flowing properly

solution hose connection

Screen in filter clogged

Valve clogged

98461

SOLUTION

Check building circuit breaker or fuse box.

Replace.

Rep

I

ace.

Follow grounding instructions exactly.

Contact an electrician

to

check building's

..

Have a trained service technician check machine's

wiring.

Replace.

Replace.

Replace.

Center and seal dome over tank.

Replace or repair using acrylic plastic cement only.

With power off clean screen.

Tighten cuffs turning counterclockwise.

Replace.

Wash out with hose. Pick lint out with a wire.

Replace.

Check

for

positive connection

Remove and clean with hot water.

Clean or replace if damaged. Check

to

be sure

filter screen is in place. Be sure

to premix cleaning

chemicals.