COMMODORE

THE

COMMODORE

FILL SOLUTION TANK

to

the desired

according

to

the marked gauge

inside the tank.

CAUTION:

If a bucket

used

to

fill the tank, be sure that it

Is clean.

CAUTION:

To avoid oossible distortion

of polyethylene

tanks,

DO NOT USE WATER TEMPERATURE

THAT EXCEEDS

150°F

(65°C).

ARE

PREFERRED,

however if a powdered detergent is

used, be sure

it

is fully dissolved

BEFORE

putting

it

in the solution tank.

Do

this by dissolving it in a bucket

containing about

1

gallon of hot water

before emptying it into the solution tank.

You will find a

1

cup (8

measure

on the bottom of the solution tank lid

to

assist you in making the proper

dilution of cleaning chemical and water.

WARNING:

Do not put defoamer.

solvents, spotter or prespray chemicals

in the solution tank.

CHEMICALS

The internal parts of the pump used in

the extractor is suitable for use with

most carpet cleaning chemicals. But it

is susceptible

to

chemical attack from

some cleaning substances, such as

hydrocarbon solvents and chlorinated

These noncompatible materials

are not of the type normally used for

carpet cleaning,

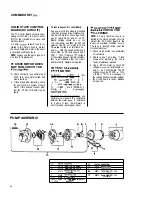

SUITABLE

CHEMICALS

CHEMICALS

Aldehydes

Clomx

Bleach’

Hydrocarbons

Agents

But

Detergents

Tetrachloride

Hydroxides

Oxygen

Bleaches

Chlorinated

Bleaches

soaps

Chlorinated

Hydrocarbons

Softener’

1

Vinegar

(MEK)

White Monday Bleach’

Phenols

PLACE RECOVERY DOME

atop recovery

tank, being sure that gasket material

is undamaged and making a good seal

with the recovery tank. Connect hose

from

shoe

to

dome.

1.

4

ATTACH ELECTRIC CABLE

connection at rear of control panel

beneath operating handle.

.

Note that all switches are in

“off”

position when attaching Twist-Lok.

.

Attach cable strain reliever as shown

to

prevent damage

to

power cord

connections.

INSTRUCTIONS

This appliance must be grounded. If

it

should malfunction or breakdown,

grounding provides a path of least re-

sistance for electric current

to

reduce

the risk of electric shock. This appliance

is equipped with a cord having an

equipment-grounding conductor and

grounding plug. The plug must be

plugged

an appropriate outlet that

is properly Installed and grounded

accordance with all local codes and

ordinances.

WARNING;

con-

nection of the equipment-grounding con-

ductor can result in a risk

of

electrical

shock. Check with a

electrician

or

person if you are in doubt

as

to

whether the outlet is properly

grounded. Do not modify the plug pro-

vided with the appliance

-

it

will not

fit the outlet, have a proper outlet in-

stalled by a qualified electrician.

This machine is for use on a nominal

120-volt circuit, and has a grounded

plug that looks llke the plug illustrated

In

A.

A

temporary adapter that

looks like the adapter illustrated in

Figs. and C may be used to connect

this plug to a 2-pole receptacle as

shown in Fig. B if a properly grounded

outlet is not available. The temporary

adapter would be used only

a

properly grounded outlet (Fig.

A)

can

be installed by a qualified electrician.

The green colored

ear, lug, or the

llke extending from the adapter must

be connected to a permanent ground

such as a properly grounded outlet

cover. Whenever the adapter

used,

it

must be

in

TO

CLEAWINQ:

FOLLOW THE SEQUENCE BELOW.

.

.

1. Set

forward speed

control knob.

2.

Press

“drive” motor switch

to “on”

position. Red light will glow.

3.

Press “solution” switch

to

“on”

position. Red light will glow.

4.

Release “Brush Motor Lever”

to

“on” position and adjust brush to

correct cleaning height. The brush

setting Is correct when the bristles

the surface of the carpet.

NOTE:

Starting the machine with

dry bush resting on the carpet may

trip circuit breaker.

5.

Press down on clutch lever to start

forward movement.

WARNING:

Do not secure clutch lever

in “down” position. Damage

to

machine could occur.

6. Release vacuum lever to “on”

position

to

start

motor

and

lower

shoe

to

carpet.

TO

STOP

FOLLOW THE SEQUENCE BELOW

.

. .

1.

Push solution switch

to

“off”

(2

or

3

2.

Release clutch lever.

3.

Lift brush lever

to

“off” position.

Lift vacuum lever to “off” position.

5.

Push drive motor switch

to

”off”

position.

WARNING:

The drive train of the

COMMODORE is

FREE WHEELING

and the machine should not

be

left

unattended or used on sloping sur-

faces or ramps.

feet before end

of pass.)

TO PULL THE COMMOOORE IN RE-

VERSE,

or go forward without power

...

first raise vacuum and brush levers

to

“off” position.

’

Summary of Contents for COMMODORE CMD

Page 11: ...COMMODORE 115V CONTROL PANEL ASSEMBLY I COMMOOOAE CONTROL PANEL ...

Page 12: ...2 CHASSISWIDRIVE ASSEMBLY ...

Page 14: ...COMMODORE 1 15V 14 ...

Page 16: ...COMMODORE 115V SQtUTION RECOVERY TANKS 16 ...

Page 18: ...COMMODORE 115V CONTROL PANE1 WIRING DIAGRAM 230VOLT CHASSIS WIRING DIAORAM 230 VOLT A I8 i 18 ...