17

OPM-141/E

6. Do not conduct any welding or other heat producing

work around the oil system.

7. Ensure no tools, loose parts, or cloths are left on or on

the

system.

8. Prior to using the unit, check whether the operating

pressure, temperatures, time settings, and the oil levels

are correct. Also check that the control and switch-off

devices function properly.

CHECKING THE OIL LEVEL

Oil level can only be checked at the oil filler opening.

NOTE:

The screw cap has a safety hole on the side, oil or air

escapes if there is any residual pressure in the tank.

1. Switch off the compressor and disconnect the battery

to prevent the engine from starting.

2. Wait one minute at standstill.

3. Screw off plug of the filler neck by hand with the oil

level

depressurized.

4. Check the oil level. Reference the previous diagram.

5. If necessary, top off oil to the maximum level.

6. Screw on the plug firmly by hand.

7. Switch on the system.

8. Check the plug for any leaks, replace the o-ring if

necessary.

9. Carefully remove escaped, excess oil.

CHANGING THE OIL

Refer to the maintenance schedule chart for required oil

change intervals.

WINCO recommends our Rotorcomp maintenance kit,

which includes 1 gallon of IAT-RS8000 oil and filters.

WARNING: PERSONAL INJURY

Rotating, pressurized, and hot components. The oil

change can only be changed at a standstill and with the

compressor system completely discharged.

NOTE:

Dispose of the used oil according to applicable

regulations.

1. Switch off the compressor and disconnect the battery

to prevent the engine from starting.

7.2

[en] 02/2014

Installation and operating manual - NK 31

ROTORCOMP VERDICHTER

7.2 Oil level

An important factor for the operating safety of the

system is the oil level in the oil reservoir.

The oil level check must be carried out before

commissioning the screw compressor module

and then repeated every 100 operating hours..

The exact oil level check can only be carried out

via the oil

fi

ller opening.

Warning

Rotating, pressurized and hot components,

DANGER OF INJURY!

7.2.1 Oil level check via oil

fi

ller opening

Warning

– The unit parts, oil and oil

fi

ller plug

1

may be

over 80°C/176°F; danger of burns!

Wear personal safety equipment!

– With hot oil, the oil level can be approx. 10 mm

higher than with cold oil shortly after discharg-

ing.

As a result, oil may escape when the oil

fi

ller

plug is opened at the maximum oil level. In

this case, close the oil

fi

ller plug again imme-

diately and carefully remove the oil which has

escaped.

Figure 7-1

Note

The screw cap of the oil

fi

ller neck is provided

with a safety hole on the side from which oil or air

escapes if there is any residual pressure in the

separating tank. Wait brie

fl

y in this case.

• Switch off the system and secure it against

unauthorized switch-on.

• Wait for one minute at standstill.

• Screw off the screw plug

1

of the

fi

ller neck by

hand with the oil level depressurized.

• Check the oil level.

• If necessary, top up oil of the same oil type and

the same brand up to the maximum level.

MAX

MIN

1

7.3

[en] 02/2014

Installation and operating manual - NK 31

Note

The oil

fi

ller neck is positioned so that over

fi

lling

of the screw compressor system is not possible.

Excess oil runs out of the

fi

ller neck again.

• Screw on the screw plug

1

fi

rmly by hand.

• Switch on the system.

• Check the oil

fi

ller plug for leaks and replace

the O-ring if necessary.

• Carefully remove escaped, excess oil.

7.3 Oil change

Warning

Rotating, pressurized and hot components,

DANGER OF INJURY

The oil change may only be carried out at a

standstill and with the screw compressor system

completely discharged.

7.3.1 Oil change intervals

According to the speci

fi

cations of the system

manufacturer.

For the reference values for the screw compres-

sor compact module, see chapter

7.8

“Mainte-

nance intervals”.

7.3.2 Oil drain points

The system should be at operating temperature

in this case.

Figure 7-2

Note

Dispose of the used oil according to the appli-

cable regulations.

• Switch off the screw compressor and then

secure it against being switched on again by

removing the main switch.

• Completely release the pressure in the screw

compressor system.

• Slowly screw off the screw plug on the oil

fi

ller

neck.

• Carefully unscrew the oil drain screw

1

and

catch the used oil in a suitable container.

• Clean the oil drain screw

1

and screw in again.

1

2. Completely release the pressure

in the system.

3. Slowly screw off the screw plug

on the oil filler neck.

4. Unscrew the oil drain screw

(ref. 1) and drain the used

oil into an approved container.

5. Clean the oil drain screw and screw back in.

6. Replace the oil filter if necessary. See Changing Oil

Filter of the Air Compressor section of this manual.

7. Refill with new oil at the filler neck to the maximum

level.

NOTE:

The compressor must be operated with an oil

suitable for special requirements. This oil must be approved

by the manufacturer for screw compressors. It must even

be suitable under unfavorable operating conditions, such

as soiling of the intake air with gases, solvent vapors and

exhaust gases and at high ambient temperatures. Suitable

oil types and oil manufacturers can be specified for screw

compressor on request.

Refined oils (mineral oils) synthetic oils and bio oils

(biodegradable) can be used as screw compressor oil. The

materials and gaskets used in the screw compressor system

must be taken into account when selecting the oil type.

Corrosion and other material damage may not occur. It is

not permissible to mix different oils.

This compressor requires 101.4 ounces (3.17 quarts) of oil if

it is completely drained. Use caution when refilling.

8. Turn on the compressor and allow to run for 3 minutes.

9. Check oil level. Top off to the maximum level if needed.

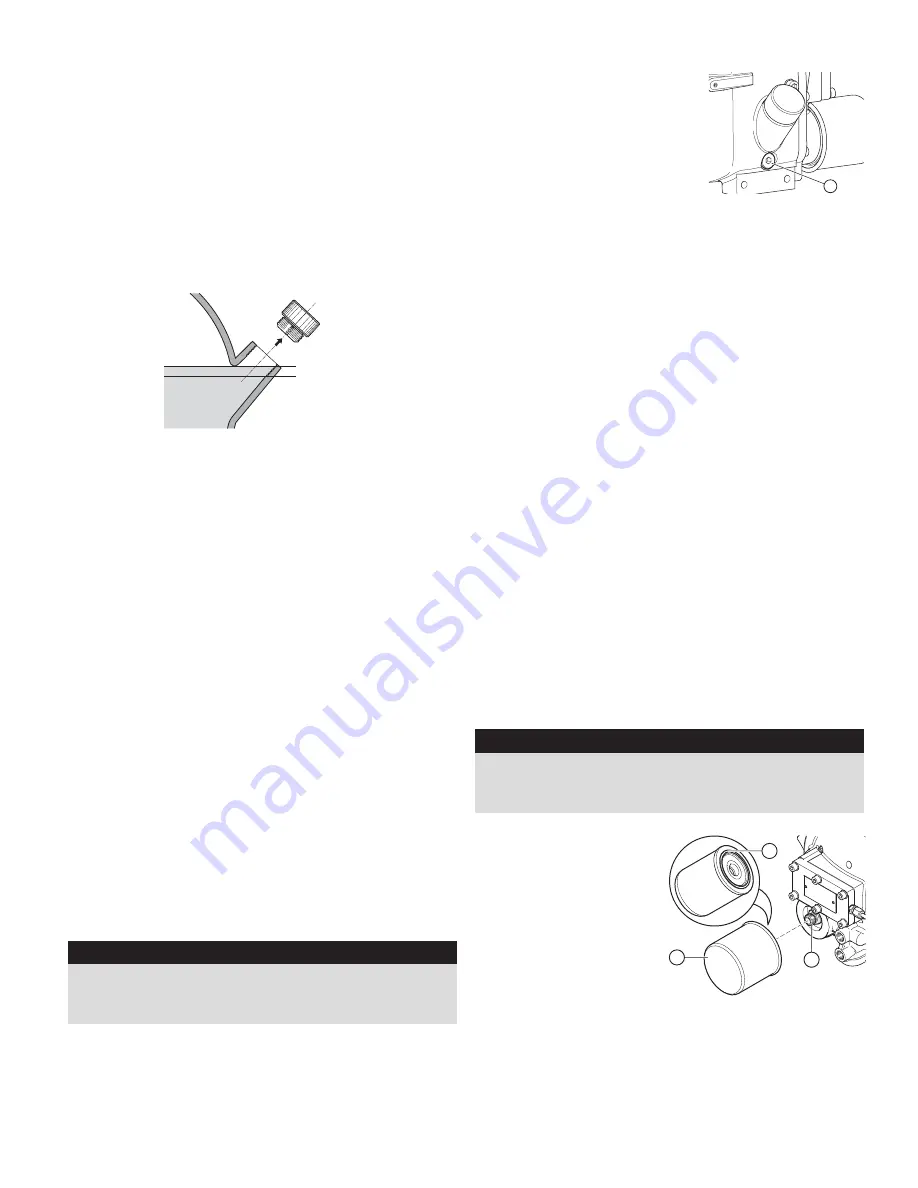

CHANGING THE OIL FILTER

WARNING: PERSONAL INJURY

Rotating, pressurized, and hot components. The oil

change can only be changed at a standstill and with the

compressor system completely discharged.

1. Switch off the

compressor

and

disconnect the battery

to prevent the engine

from

starting.

2. Remove the oil filter

cartridge (Ref. 1) with

a suitable tool, i.e. oil

filter strap wrench.

3. Oil the gasket (Ref. 2.) on the new filter cartridge with

the same oil type in use with the compressor.

4.Screw the new oil filter cartridge on (Ref. 3) and tighten

by

hand.

5. Switch on the compressor.

7.4

[en] 02/2014

Installation and operating manual - NK 31

ROTORCOMP VERDICHTER

7.3.3 Filling with oil

Attention

Observe the oil recommendation, see “Lubricants

and Operating Materials”. Add oil of the same oil

type from the same manufacturer.

Switching over to another oil type can require the

compressor module to be

fl

ushed.

ROTORCOMP recommends also replacing the

oil

fi

lter during an oil change.

• Replace the oil

fi

lter if necessary

• Pour oil into the

fi

ller neck on the separator

tank up to the maximum level and screw the

screw plug

1

onto the

fi

ller neck by hand

(see Figure

7-2

).

• Switch on the screw compressor and allow it to

run for approx. three minutes.

• Oil level check:

Top up the missing oil quantity again up to the

maximum level.

• Check sheet entry (see chapter

7.7

“Mainte-

nance check sheet”).

7.4 Oil

fi

lter

Warning

Rotating, pressurized and hot components,

DANGER OF INJURY

– The unit parts, oil and oil

fi

ller plug may be

over 80°C/176°F; danger of burns!

– Wear personal safety equipment!

The oil

fi

lter replacement may only be carried

out at a standstill and with the screw compressor

system completely discharged.

7.4.1 Oil

fi

lter replacement intervals

According to the speci

fi

cations of the system

manufacturer.

For the reference values for the screw compres-

sor compact module, see chapter

7.8

“Mainte-

nance intervals”.

7.4.2 Oil

fi

lter replacement

Figure 7-3

• Switch off the system and completely release

the pressure in the system.

• Remove the oil

fi

lter cartridge

1

with a suitable

tool, e.g. oil

fi

lter strap wrench.

• Oil the gasket

2

on the new oil

fi

lter cartridge

1

with oil of the same oil type as in the compres-

sor module.

Note

Dispose of the old oil

fi

lter cartridge according to

the applicable regulations.

• Screw the new oil

fi

lter cartridge onto the con-

nection nipple

3

and tighten by hand. No tool is

required.

• Switch on the screw compressor.

• The oil

fi

lter must then be checked for leaks

with the system running.

• Oil level check:

Top up the missing oil quantity again up to the

maximum level.

• Check sheet entry (see chapter

7.7

“Mainte-

nance check sheet”).

1

2

3

Summary of Contents for DE4040F4

Page 31: ...31 OPM 141 E ENGINE HARNESS ...