18

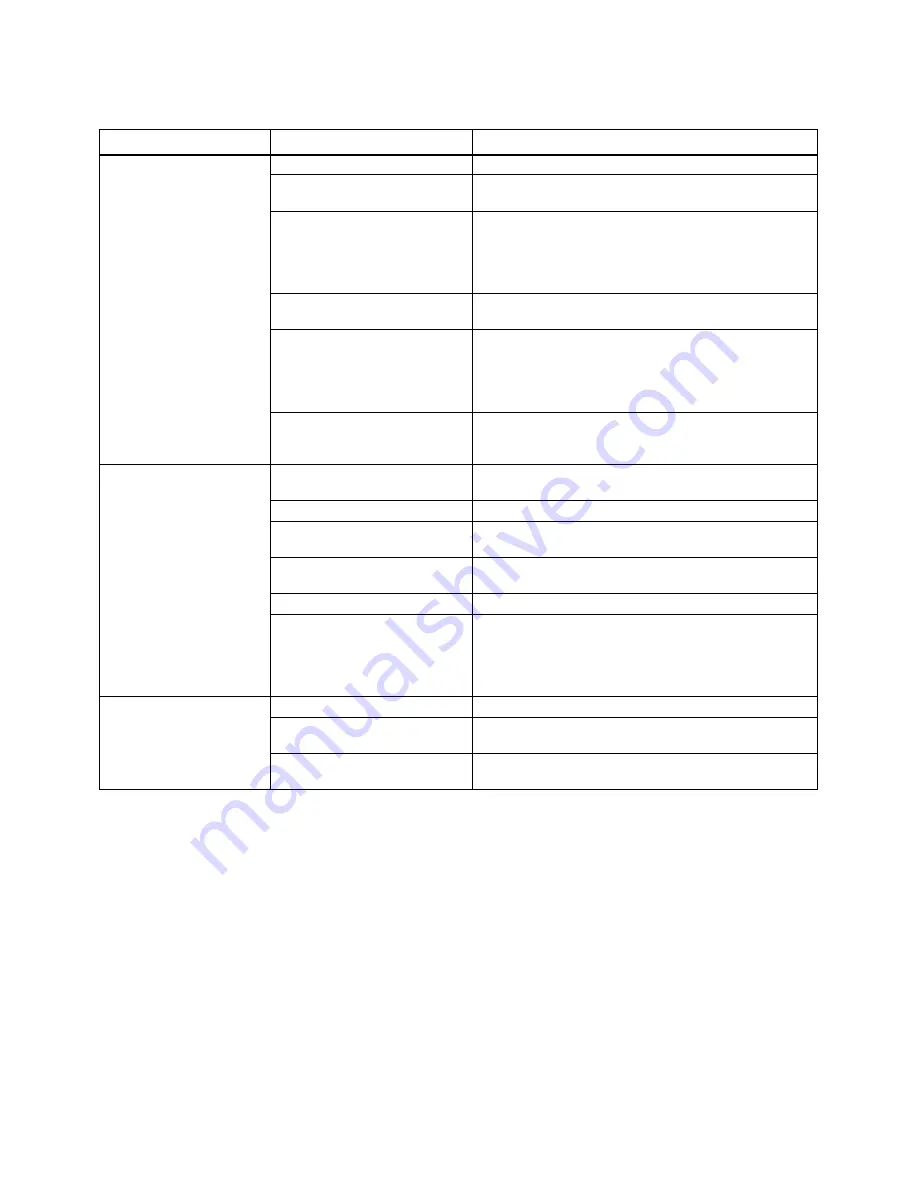

Troubleshooting

Troubleshooting – Blade and Cutting Problems

Problem Probable

Cause

Solution

Incorrect lubricant/coolant fluid

Ensure proper coolant flow.

Material too hard

Check the cutting speed, feed speed and air pressure

parameters and the type of blade you are using.

Disc not worn--in correctly

With a new blade it is necessary to start cutting at half

feeding speed. After the wearing--in period (a cutting

surface of about 300 cm2 for hard materials and about

1000 cm2 for soft materials) the cutting and feed

speeds can be brought up to normal values

Disc with excessively fine

tooth pitch

The swarf wedges into the bottom of the teeth causing

excessive pressure on the teeth themselves

New blade inserted in a

partially completed cut

The surface of the cut may have undergone work

hardening. When starting work again, use a lower

cutting speed and head feed speed. A tooth from the

old blade may be left in the cut: check and remove

before starting work again.

Teeth breaking

Work piece not clamped firmly

in place

Any movement of the work piece during cutting can

cause broken teeth: check the vise, jaws and clamping

pressure.

Feed speed too slow

The blade runs over the material without removing it:

increase feed speed.

Cutting pressure too high

Reduce cutting pressure.

Blade speed too high

The teeth slide over the material without cutting it:

reduce the blade speed.

Insufficient coolant

Check the coolant level and clean coolant lines and

nozzles.

Incorrect fluid concentration

Check and use the correct concentration.

Rapid tooth wear

Material defective

The materials may present altered zones either on the

surface, such as oxides or sand, or in section, such as

under-cooled inclusions. These zones, which are

much harder than the blade, cause the teeth to break:

discard or clean these materials.

Feed speed too high

Reduce blade speed.

Teeth in contact with material

before starting the cut

Always check the position of the blade before starting

a new job.

Broken blade

Insufficient coolant

Check the coolant level and clean coolant lines and

nozzles.

Summary of Contents for -SX

Page 7: ...7 FK350 Features FK350 Cold Saw FK350 SX Cold Saw ...

Page 21: ...21 Head Assembly FK350 FK350 SX ...

Page 23: ...23 Power Feed Assembly FK350 SX ...

Page 27: ...27 Stand Assembly FK350 SX ...

Page 29: ...29 Base Assembly FK350 ...

Page 31: ...31 Base Assembly FK350 SX ...

Page 33: ...33 Manual Vise Assembly FK350 ...

Page 35: ...35 Power Vise Assembly FK350 SX File 27 ...

Page 37: ...37 Guard Assembly FK350 FK350 2SX ...

Page 40: ...40 Pneumatic Drawing FK350 SX Wiring Diagram FK350 ...

Page 41: ...41 Wiring Diagram FK350 SX ...

Page 42: ...42 NOTES ...

Page 43: ...43 NOTES ...