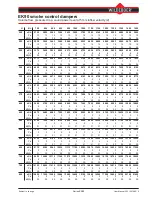

User Manual 5.32 (2018-05) 21

Subject to change

Series EK92

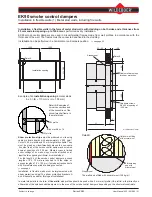

EK90 smoke control dampers

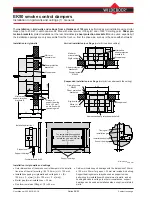

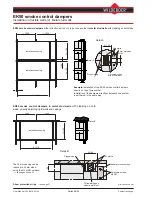

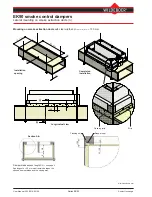

Installation in flexible walls (1) Metal stud walls, including fire walls

Installation

in

flexible walls in the form of metal stud walls with cladding on both sides and a thickness from

95 mm and stud spacing up to 1000 mm

is performed as dry installation.

EK90 smoke control dampers are used in circumferential frames made from wall profiles, in accordance with the

thickness of the wall. The frames must be connected and fixed to the studding.

Installation can be performed in a horizontal or vertical axis position.

⇒

see page 33

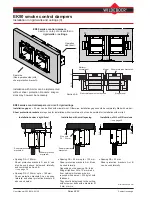

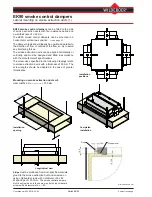

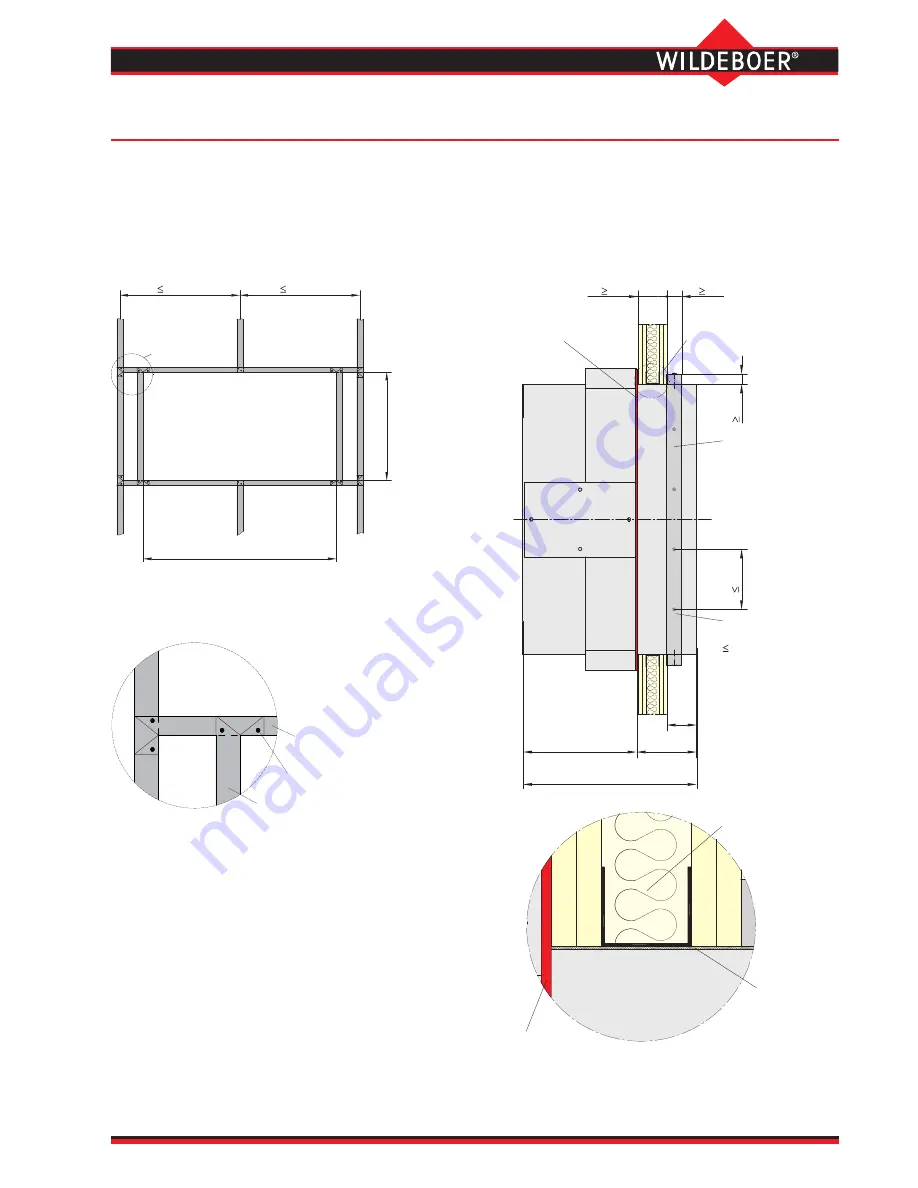

Detail B:

Shear protection strips

must be produced on site using

calcium silicate boards with approximately ≥ 500 kg/m³.

Cuts of ≥ 50 mm width and 35 mm height are suitable. They

must be glued on circumferentially around the non-opera

-

tion side (rear) of the smoke control damper and screwed

down at spacings of ≤ 200 mm. Where access is limited

under ceilings or on walls, strips must be attached on at

least the two opposing horizontal or vertical sides!

For the length L of the smoke control dampers, excess

lengths of Z ≥ 70 mm are required to fit the strips, or

excess lengths of Z ≥ 100 mm if smoke extraction ducts

with fire resistance period are being connected.

⇒

see page 4

Installation in flexible walls must be implemented with

shear protection strips! The shear protection brackets A

and B cannot be used for this type of installation!

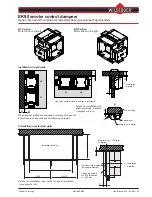

Detail A: Examples of

corner connections and

of the connection of the

circumferential frame to

the metal studs.

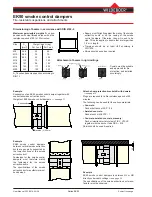

Example of an

installation opening

in metal studs

b x h = (B + 110 mm) x (H + 105 mm)

The wall can be filled with mineral wool

≤

100 kg/m³.

In metal stud walls in the form of

fire walls

, stud profiles should be used with a 2 mm wall profile (UA profile), either directly on

either side of the smoke control dampers or in the area of the smoke control dampers, depending on the structural constraints.

All dimensions in mm

CW profile

Blind rivet Ø4.8 x 7.5

UW profile

Installation opening

1000

1000

50

1

+

H

B + 110

Detail A

Chipboard screws

Ø4 x 60 at spacing of

200 mm

Stopper seal

Calcium silicate strips

for shear protection

200

35

50

W 95

L1

L2

L

Detail B

Z

Optional wall filling

with mineral wool

Stopper seal

Fill remaining

gap with

mineral wool