12

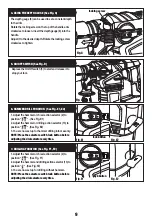

1. Reduce the pressure on the drill bit when it is about to break through. This will prevent the drill from jamming.

2. When drilling a large hole, first drill a pilot hole using a smaller drill bit.

3. Always apply pressure to your drill bit in a straight line, and if possible at right angles to the workpiece.

4. Never change the operating mode whilst the drill is running.

5. Do not apply excessive pressure to the tool when chiseling. Excessive force does not speed up the work.

Remove the plug from the socket before carrying out any adjustment, servicing or maintenance.

There are no user serviceable parts in your power tool. Never use water or chemical cleaners to clean your power tool.

Wipe clean with a dry cloth. Always store your power tool in a dry place. Keep the motor ventilation slots clean. Keep all

working controls free of dust. Occasionally you may see sparks through the ventilation slots. This is normal and will not

damage your power tool.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in

order to avoid a hazard.

WORKING HINTS FOR YOUR ROTARY HAMMER DRILL

MAINTENANCE

TROUBLESHOOTING

ENVIRONMENTAL PROTECTION

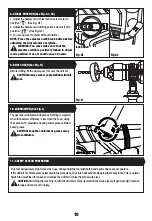

1. If your power tool does not start, check the plug on the power supply first.

2. If your drill becomes too hot in use, set the hammer switch to the drill mode and allow your drill to operate at maximum

speed without load for 2 minutes.

3. If your hammer work efficiency is too low, please add sufficient grease in the grease box.

4. If work efficiency is too low please check drill bit or chisel and make sure it is not blunt or worn.

5. If a fault can not be rectified, return the tool to an authorized dealer for repair.

Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist.

Check with your Local Authority or retailer for recycling advice.

Summary of Contents for 223724

Page 1: ...PDH32DS 2 223724 ROTARY HAMMER 1500W...

Page 15: ......

Page 16: ...Customer Helpline 0345 2005409...