Page 15

22992-0-1106

CAUTION: ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH ALL LOCAL, CITY AND STATE BUILDING CODES. BEFORE MAKING THE ELECTRICAL CONNECTION,

MAKE SURE THAT MAIN POWER SUPPLY IS DISCONNECTED. THE APPLIANCE, WHEN INSTALLED, MUST BE

ELECTRICALLY GROUNDED IN ACCORDANCE WITH LOCAL CODES OR, IN THE ABSENCE OF LOCAL CODES,

WITH THE NATIONAL ELECTRICAL CODE ANSI/NFPA 70 (LATEST EDITION)

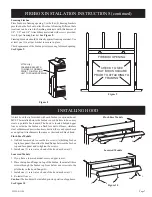

A factory installed junction box is located on the lower right

hand side of the firebox. Wiring must be fed to the junction

box and attached to the receptacle that is provided. Remove the

knockout in the installed junction box to accept wiring into the

junction box. Install a UL listed cable clamp (not supplied) in the

knockout hole. Leave approximately 6" of wire in the junction

box for connection.

Attach black wire to one side of the receptacle and white wire to

opposite side of receptacle. The ground wire should be attached

to the green (neutral) screw.

Install the receptacle into the junction box. Attach cover plate.

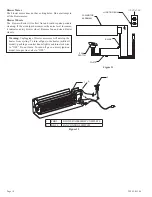

Keep the control compartment, logs and burner area surrounding the

logs clean by vacuuming or brushing area at least twice a year.

THE LOGS CAN GET VERY HOT – HANDLE ONLY WHEN

COOL.

Always turn off gas to the pilot before cleaning. For relighting,

refer to lighting instructions located on the log set.

Never obstruct the flow of the combustion and ventilation air. Keep

the front of the firebox clear of all obstacles and materials.

Screens must be closed during operation.

Figure 33

JUNCTION BOX WIRING INSTALLATION INSTRUCTIONS

MAINTENANCE