10

6. Repeat Steps 1 and 2 to ensure that the range foot is

engaged in the anti-tip bracket.

If the rear of the range lifts more than ½" (1.3 cm) off the floor

without resistance, the anti-tip bracket may not be installed

correctly. Do not operate the range without anti-tip bracket

installed and engaged. Please reference the “Assistance or

Service” section of the Use and Care Guide, or the cover or

“Warranty” section of the User Instructions, to contact

service.

Level Range

Determine if you have AquaLift

®

Technology or Steam Clean by

referring to the “Range Care” section of the User Instructions.

For Ranges with AquaLift

®

Technology or Steam Clean:

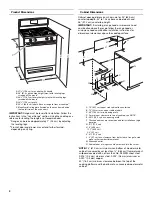

1. Place level on the oven bottom as indicated in one of the two

figures below depending on the size of the level. Check with

the level side to side and front to back.

2. If range is not level, pull range forward until rear leveling leg is

removed from the anti-tip bracket.

3. Follow the directions in Style 1 or Style 2, depending on the

style of drawer supplied with the range.

For Ranges without AquaLift

®

Technology or Steam Clean:

1. Place a standard flat rack in oven.

2. Place level on the rack and check levelness of the range, first

side to side; then front to back.

3. If range is not level, pull range forward until rear leveling leg is

removed from the anti-tip bracket.

4. Follow the directions in Style 1 or Style 2, depending on the

style of drawer supplied with the range.

Style 1: Ranges Equipped with a Storage Drawer:

Use

a ¼" drive ratchet, wrench or pliers to adjust leveling legs

up or down until the range is level. Push range back into

position. Check that rear leveling leg is engaged in the anti-tip

bracket.

Style 2: Ranges Equipped with a Warming Drawer or

Premium Storage Drawer:

Use a wrench or pliers to adjust leveling legs up or down until

the range is level. Push range back into position. Check that

rear leveling leg is engaged in the anti-tip bracket.

NOTE: Range must be level for satisfactory baking

performance and best cleaning results using AquaLift

®

Technology and Steam Clean functions.

Electronic Ignition System

Initial lighting and gas flame adjustments

Cooktop and oven burners use electronic igniters in place of

standing pilots. When the cooktop control knob is turned to the

“LITE” position, the system creates a spark to light the burner.

This sparking continues, as long as the control knob is turned to

“LITE.”

When the oven control is turned to the desired setting, sparking

occurs and ignites the gas.

Check Operation of Cooktop Burners

Standard Surface Burners

Push in and turn each control knob to the “LITE” position.

The flame should light within 4 seconds. The first time a burner is

lit, it may take longer than 4 seconds to light because of air in the

gas line.

If burners do not light properly:

■

Turn cooktop control knob to the “OFF” position.

■

Check that the range is plugged in. Check that the circuit

breaker has not tripped or the household fuse has not blown.

■

Check that the gas shutoff valves are set to the “open”

position.

■

Check that burner caps are properly positioned on burner

bases.

Repeat start-up. If a burner does not light at this point, turn the

control knobs to the “OFF” position and contact your dealer or

authorized service company for assistance.

Adjust Flame Height

Adjust the height of top burner flames. The cooktop “low” burner

flame should be a steady blue flame approximately ¼" (6.4 mm)

high.

To adjust standard burner:

The flame can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located directly

underneath the control knob.

A. Low flame

B. High flame

A

B