6

LFP580GR

e.

Spin Drying

Yes

No

TROUBLE

INSPECTION

CAUSES

REMEDY

INSPECTION

Drain takes time too

long.

Valve bellows is deformed.

Drain hose

ass

’

y is

deformed.

Hose is connected in the

wrong way.

Hose is too long or position of

hose is too high.

Replace.

Repair or replace.

Repair.

Repair.

Note: In draining, the water lever sensor can

not reset in 8minutes.

The number window LED display

abnormal code: and begin blinking

on and off at the same time and the

electric buzzer sounds to indicate a

problem.

Note: In draining, the water level sensor can

not reset in 8minutes.

Four of the course lamp (NORMAL

、

DELICATE

、

BLANKET

、

ECO-SPEEDY) begin blinking on and

off at the same time and the electric

buzzer sounds to indicate a problem.

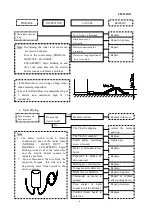

• If the Drain Hose is too long or high, it may

make draining impossible.

• The extend Drain Hose to a maximum long of

3 meters and maximum high of 10

centimeters.

Spin drying cycle

does not work.

INSPECTION

Does safety

device work?

Machine inclines.

Replace with lever.

The V-belt is slipping.

The V-belt is snapped.

Small pulley mounting

screw is loosed.

Motor is disconnected or

burnt.

Capacitor is broken or

disconnected.

Bearing ass

’

y is defective.

Torque motor is defective.

Brake lever is defective.

Thermostat on motor is

opened.

Poor contact of 6-pin

connectors (blue &white).

Control circuit board is

defective.

Adjust the motor

position.

Replace.

Tighten up.

Replace.

Replace.

Replace.

Replace.

Repair or replace.

Repair or replace

after cooling down.

Repair or replace.

Replace.

Note:

1.

The safety switch works 3 times

continuously. Four of the course lamp

(NORMAL

、

HEAVY

DUTY

、

BLANKET

、

ECO-SPEEDY) begin

blinking on and off at the same time

and the electric buzzer sounds to

indicate a problem.

2. Do not disconnect the wire from the

capacitor, because this wire acts as

de-pressing noise from outside to the

micro-computer.

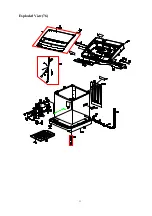

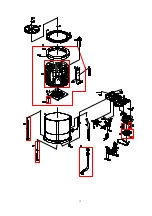

Summary of Contents for LFP580GR

Page 11: ...11 Exploded View 76 ...

Page 12: ...12 ...