5

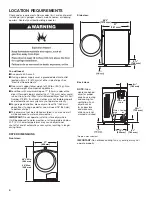

Installation spacing for recessed area or closet

installation:

All dimensions show recommended and minimum spacing allowed.

■

Additional spacing should be considered for ease of

installation and servicing.

■

Additional clearances might be required for wall, door, floor,

moldings, and drain system.

■

Additional spacing should be considered on all sides of the dryer

to reduce noise transfer.

■

For closet installation, with a door, minimum ventilation openings

in the top and bottom of the door are required. Louvered doors

with equivalent ventilation openings are acceptable.

■

Companion appliance spacing should also be considered.

Recommended installation clearances (dryer only):

Mobile home – Additional installation requirements:

This dryer is suitable for mobile home installations. The

installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile

home construction and Safety, Title 24, HUD Part 280)

or Standard CAN/CSA-Z240 MH.

18" min.

(457 mm)

1"

(25 mm)

5"

(127 mm)

24 in.

2

min.

(155 cm

2

)

48 in.

2

min.

(310 cm

2

)

3"

(76 mm)

3"

(76 mm)

1"

(25 mm)

*NOTE:

0" (0 mm)

spacing is allowed

behind dryer, providing

drain hose is not kinked

or pinched.

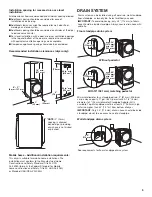

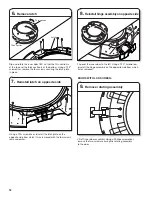

DRAIN SYSTEM

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum

carry-away capacity: 17 gal. (64 L) per minute. A 1/4" (6 mm)

diameter to 1" (25 mm) diameter Standpipe Adapter Kit is

available. Top of standpipe must be at least 30" (762 mm) high;

install no higher than 54" (1.37 m) from bottom of dryer.

IMPORTANT:

Only 4.5" (114 mm) of drain hose should be inside

standpipe; do not force excess hose into standpipe.

Wall standpipe drain system

4.5"

(114 mm)

Floor standpipe drain system

See requirements for floor standpipe drain system.

Drain system can be installed using a floor drain, wall standpipe,

floor standpipe, or laundry tub. Select method you need.

IMPORTANT:

To avoid siphoning, only 4.5" (114 mm) of drain

hose should be inside standpipe. Always secure drain hose with

cable tie.

4.5"

(114 mm)

4.5"

(114 mm)

max. 54"

(1372 mm)

min. 30"

(762 mm)

4.5"

(114 mm)

4.5"

(114 mm)

max. 69"

(1753 mm)

min. 30"

(762 mm)

With 15" (381 mm) matching pedestal

Without pedestal

0" – 5"*

(0 mm – 127 mm)