5

■

Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

If you have questions about your water pressure, call a licensed,

qualified plumber.

Leveling

It is important for the ice maker to be level in order to work

properly. Depending upon where you install the ice maker, you

may need to make several adjustments to level it. You may also

use the leveling legs to lower the height of the ice maker for

undercounter installations.

Tools needed:

Gather the required tools and parts before starting installation.

■

9" level

■

Adjustable wrench

NOTE: It is easier to adjust the leveling legs if you have another

person to assist you.

1. Move the ice maker to its final location.

NOTE: If this is a built-in installation, move the ice maker as

close as possible to the final location.

2. Place a carpenter’s level on top of the product to see if the ice

maker is level from front to back and side to side.

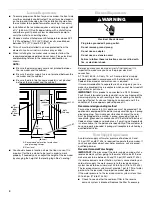

3. Push up on the top front of the ice maker, and then locate the

leveling screws that are on the bottom front of the ice maker.

4. Using an adjustable wrench, change the height of the legs as

follows:

■

Turn the leveling leg to the right to lower that side of the

ice maker.

■

Turn the leveling leg to the left to raise that side of the ice

maker.

NOTE: The ice maker should not wobble. Use shims to add

stability when needed.

5. Push up on the top rear of the ice maker and locate the

leveling legs that are on the bottom rear of the ice maker.

6. Follow the instructions in Step 4 to change the height of the

legs.

7. Use a carpenter’s level to recheck the ice maker to see that it

is even from front to back and side to side. If the ice maker is

not level, repeat steps 2 to 5. If the ice maker is level, go to

the “Connect Water Supply” section.

Connect Water Supply

Read all directions thoroughly before you begin.

IMPORTANT:

■

Plumbing shall be installed in accordance with the

International Plumbing Code and any local codes and

ordinances.

■

Use copper tubing and check for leaks.

■

Install copper tubing only in areas where temperatures will

remain above freezing.

Tools needed:

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

■

Flat-blade screwdriver

■

⁷⁄₁₆

" and

¹⁄₂

" open-end wrenches or two adjustable wrenches

■

¹⁄₄

" nut driver

■

¹⁄₄

" drill bit

■

Hand drill or electric drill properly grounded

NOTE: Your ice maker dealer has a kit available with a

¹⁄₄

"

(6.35 mm) saddle-type shutoff valve, a union, and copper tubing.

Before purchasing, make sure a saddle-type valve complies with

your local plumbing codes. Do not use a piercing-type or

³⁄₁₆

"

(4.76 mm) saddle valve which reduces water flow and clogs more

easily.

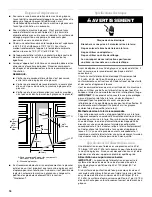

Connecting the water line

1. Turn off main water supply. Turn on nearest faucet long

enough to clear line of water.

2. Find a

¹⁄₂

" (12.70 mm) to 1

¹⁄₄

" (3.18 cm) vertical cold water

pipe near the ice maker.

NOTE: Horizontal pipe will work, but the following procedure

must be followed: Drill on the top side of the pipe, not the

bottom. This will help keep water away from the drill. This

also keeps normal sediment from collecting in the valve.

3. Using a grounded drill, drill a

¹⁄₄

" (6.35 mm) hole in the cold

water pipe you have selected.

4. Fasten shutoff valve to cold water pipe with pipe clamp. Be

sure outlet end is solidly in the

¹⁄₄

" (6.35 mm) drilled hole in the

water pipe and that the washer is under the pipe clamp.

Tighten packing nut. Tighten the pipe clamp screws carefully

and evenly so washer makes a watertight seal. Do not

overtighten the pipe clamp or you may crush cold water pipe

if it is soft copper tubing. Do not use a piercing-type or

³⁄₁₆

"

(4.76 mm) saddle-type valve which reduces water flow and

clogs more easily.

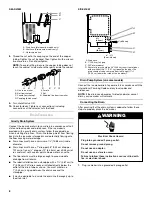

5. Now you are ready to connect the copper tubing. Use

¹⁄₄

"

(6.35 mm) OD soft copper tubing for the cold water supply.

■

Ensure that you have the proper length needed for the

job. Be sure both ends of the copper tubing are cut

square.

■

Slip compression sleeve and compression nut on copper

tubing as shown. Insert end of tubing into outlet end

squarely as far as it will go. Screw compression nut onto

outlet end with adjustable wrench. Do not overtighten.

6. Place the free end of the tubing into a container or sink, and

turn on main water supply and flush out tubing until water is

clear. Turn off shutoff valve on the water pipe.

NOTE: Always drain the water line before making the final

connection to the inlet of the water valve to avoid possible

water valve malfunction.

7. Bend the copper tubing to meet the water line inlet which is

located on the back of the ice maker cabinet as shown.

Leave a coil of copper tubing to allow the ice maker to be

pulled out of the cabinet or away from the wall for service.

A. Cold water pipe

B. Pipe clamp

C. Copper tubing

D. Coupling (purchased)

E. Compression nut

F. Compression sleeve

G. Shutoff valve

H. Packing nut

A

B

C

D

E

F

G

H