Operating position

C

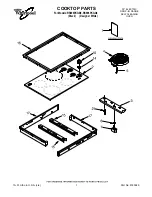

5.

Remove cardboard shipping base from

under range. Open broiler drawer. Use a 3/8”

drive ratchet to lower rear leveling legs one-

half turn. Use channel lock pliers to lower front

leveling legs one-half turn.

7.

If installing the range in a mobile

home, you MUST secure the range to the floor.

Any method of securing the range is adequate as

long as it conforms to the “Manufactured Home

Construction and Safety Standard,” Page 2.

8.

Place rack in oven. Place level on rack,

first side to side; then front to back.

If range is not level, pull range forward until

rear leveling leg is removed from the anti-tip

bracket. Use 3/8" drive ratchet and channel lock

pliers to adjust leveling legs up or down until

range is level. Push range back into position.

Check that rear leveling leg is engaged in anti-

tip bracket.

Note: Oven must be level for satisfactory

baking conditions.

Page 5

Before moving range across floor, check that

range is still on cardboard shipping base to

protect floor covering.

Gas and electrical connections

D

13.

Place burner grates over surface

burner.

14.

Plug power supply cord into

grounded electrical outlet.

12.

Use a brush and liquid detergent

to test all gas connections. Bubbles around

connections will indicate a leak. If a leak

appears, shut off gas valve controls and

tighten connections. Then check connections

again.

Never test for gas leaks with a match or

other flame.

Clean all detergent from range.

Replace storage drawer/close storage drawer.

rear leveling leg

front leveling leg

11.

Check that range regulator shutoff

valve is in the “on” position.

Open the manual

shutoff valve in the gas supply line.

manual shutoff valve

“open” position

gas supply

to range

6.

Making sure the

anti-tip bracket is

installed:

• Look for the

anti-tip bracket

securely attached to

floor.

• Slide range back so rear range foot is under

anti-tip bracket.

anti-tip

bracket

range foot

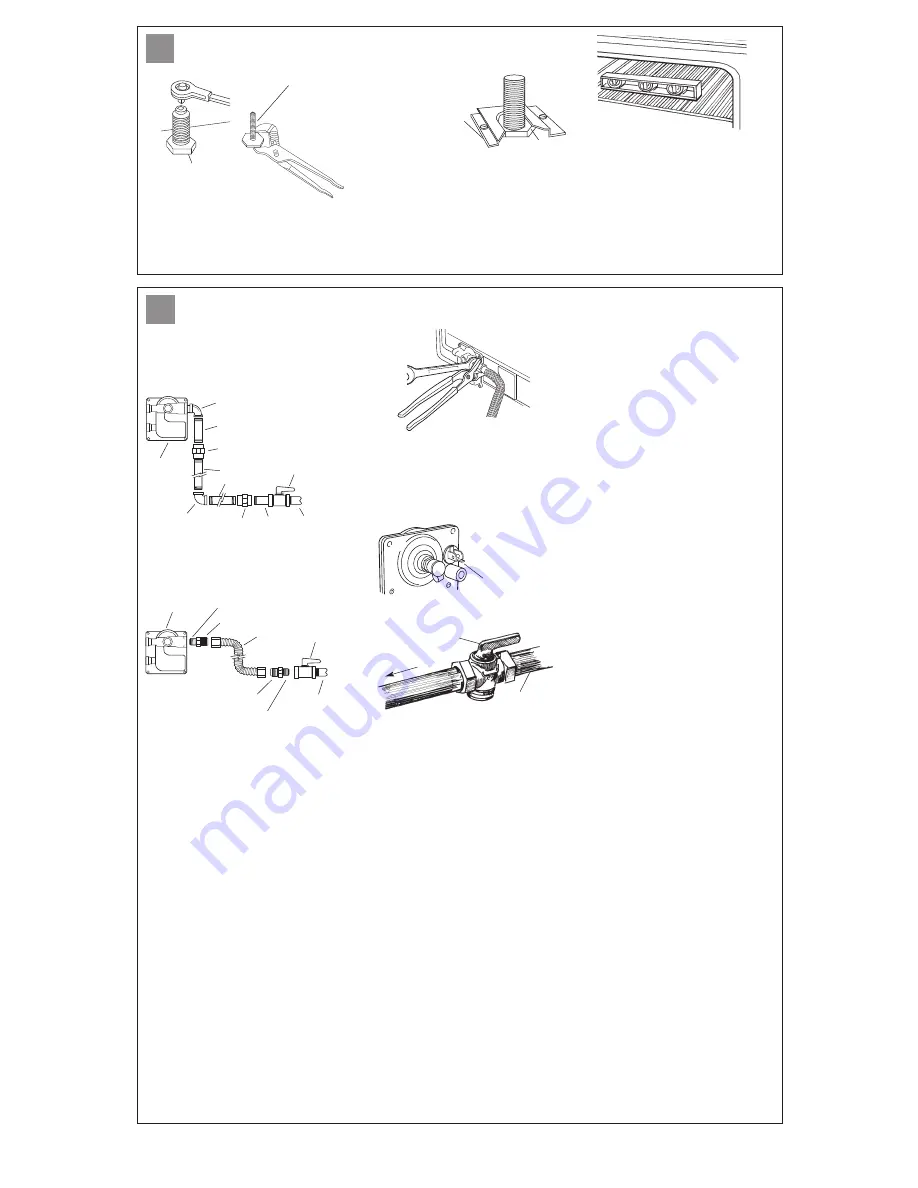

9.

Apply pipe-joint compound made for

use with L. P. gas to the smaller thread ends of

the flexible connector adapters. Attach one

adapter to the pressure regulator elbow and

the other adapter to the gas shutoff valve.

Tighten both adapters.

All connections must be wrench-tightened.

10.

Use 15/16" combination wrench and

channel lock pliers to attach the flexible

connector to the adapters. Check that connector

is not kinked.

90˚elbow

1/2" to 3/4"

gas pipe

nipple

nipple

adapter

adapter

manual

gas

shutoff

valve

manual

gas

shutoff

valve

black iron

pipe

A 1/2" male pipe thread is needed for connection to

pressure regulator female pipe threads.

union

union

pressure

regulator

90˚elbow

1/2" to 3/4"

gas pipe

pressure

regulator

Typical rigid pipe connection

Typical flexible connection

flexible

connector

use pipe-joint

compound

use pipe-joint

compound

regulator shutoff

valve in “on”

position