5 - SET-UP FOR OPERATION

0803_GB_42

- GAS KITCHENS WITH PILOT

04/2008

tool. Rinse and dry.

When reassembling the parts, make sure you place them back in the

right position.

If it is necessary to clean the oven burner (pos. 18 fig. 3) proceed as

follows:

• Remove the lower panel as described previously. Unscrew the

screw fixing the hanger (pos. 2 fig. 3) of the injector-holder (pos.

3 fig. 2), unscrew the screw (pos.5 fig. 2) fixing the burner to the

injector-holder and xtract the injector-holder from its housing;

•

Unscrew the fastening screw (pos. 19 fig. 3) of the burner and

remove it;

• Carefully clean all the holes of the burner with the aid of a tip of

a suitable size;

• Check that the smoke discharge is clear;

• Reinstall everything in reverse order.

After the replacement check the seal using a leack detector spray.

5.3 Replacing parts

All parts must be replaced by authorized technicians

only!

To replace the following parts first remove all the control knobs and

control panel (after loosening the fixing screws), then extract the

ignition wire.

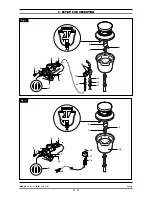

5.3.1 Open flame gas cock

Loosen the fitting of the pipes (pos. 6 and 9 fig. 1) of the gas and of

thermocouple (pos. 8 fig. 1), loosen the fitting (pos. 7 fig. 1) fixing

the cock on the gas piping and replace the piece (pos. 4 fig. 1) install

in reverse order. After the replacement check the seal using a leack

detector spray.

5.3.2 Open flame thermocouple

Loosen the nut (pos. 8 fig. 1) for fastening the thermocouple on the

valve and on the burner (pos. 17 fig. 1) and replace the piece (pos.

14 fig. 1) install in reverse order.

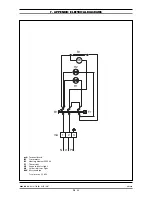

5.3.3 Gas valve gas oven GN 2/1

Loosen the fittings (pos. 1,2,3 and 4 fig. 4) which are for the connec-

tion for the gas pipe and the thermocouple, remove the coil of the

thermostat from its place in the cooking chamber and put in a new

piece in the reverse order. After the replacement check the seal

using a leack detector spray.

5.3.4 Plug gas oven GN 2/1

Unscrew the fastening screws and remove the lower panel, extract

the ignition wire and unscrew the screws (pos. 15 fig. 3), unscrew

the screw (pos. 20 fig. 3) fixing the pilot on the support, pull down

the pilot to a more convenient position and put in a new piece (pos.

16 fig. 3) install in reverse order.

5.3.5 Thermocouple gas oven GN 2/1

Unscrew the screws (pos. 15 fig. 3), the nut (pos. 4 fig. 4) fixing the

thermocouple on the valve and put in a new piece (pos. 14 fig. 3)

install in reverse order.

5.3.6 Main burner gas oven GN 2/1

Remove the front/lower panel by removing the fastening screws.

Unscrew the screws fixing the hanger (pos. 2 fig. 3) of the injector-

holder (pos. 3 fig. 3), unscrew the screw (pos.5 fig. 3) and extract

the injector-holder from its housing, unscrew the screws rear fixing

(pos. 19 fig. 3) of the burner and put in a new piece in the reverse

order. After the replacement check the seal using a leack detector

spray.

5.3.7 Cock solid top

Loosen the fitting of the pipes (pos. 6 fig. 2) of the gas and of ther-

mocouple (pos. 8 fig. 2), loosen the fitting (pos. 7 fig. 2) fixing the

cock on the gas piping and replace the piece (pos. 4 fig. 2) install in

reverse order. After the replacement check the seal using a leack

detector spray.

5.3.8 Plug solid top

Remove the solid top, the flame spreader and the burner body,

unscrew the screw (pos. 18 fig. 2), lift up the support (pos. 17 fig. 2)

pull out the spring using a pointed tool, remove the ignition plug

from the bottom, disconnect the ignition lead and insert a new

plug.

5.3.9 Thermocouple solid top

Loosen the nut (pos. 8 fig. 2) for fastening the thermocouple on the

valve and the screw (pos. 18 fig. 2) of the support (pos. 17 fig. 2)

and replace the piece (pos. 14 fig. 2).

After any maintenance or repair work, replace the con-

trol panel and the lower panel.

After replacing gas input components, check operation

again and test for leakage.

13

· 20

15

14

11

12

13

16

18

19

3

4

2

5

20

Fig. 3