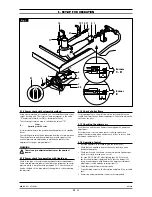

5 - SET-UP FOR OPERATION

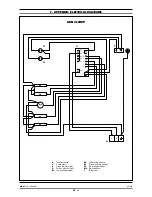

5.1.4 Power check with volumetric method

Using a gas meter and a stopwatch, you can read the volume of gas

output per time unit. The correct volume corresponds to the value

"E" expressed in litres/hour (l/h) or litre/minute (l/min).

The following formula is used to calculate the value of “E”:

It is important measure the power when the appliance is in standby

status.

The calorific power value can be requested from the local gas company.

The nominal power and the minimum power with respect to the

nominal pressure are obtained by consulting the table for the

adjustment of the gas passage (table 1).

WARNING

There is no pre-adjustment device for the nominal

power.

5.1.5 Power check for operation with liquid gas

Check if the type of nozzles used meet manufacturer requirements.

Check that the pressure reducer installed in the system has an outlet

pressure which is compliant with paragraph 5.1.2 "Check of power"

(can be checked on the data plate of the appliance or by measuring

the pressure).

E =

Power

Operating calorific value

5.1.6 Check of pilot flame

For proper regulation, the pilot flame must surround the thermo-

couple and it must have a perfect appearance. Otherwise, adjust the

air flow to the pilot.

5.1.7 Checking the primary air

Both the oven and the open flames are equipped with primary air

adjustment.

Air volume flow is correct when there is sufficient protection

against the flame rising when the burner is cold or in case of flash-

back when the burner is hot.

5.1.8 Operation Control

• Start the appliance in accordance with the instructions;

• Check that the appliance does not have any leaks by using a

leak-detecting spray.

• Check ignition and that flame on the main burner lights proper-

ly and is correctly formed, even on low;

• For oven GN 1/1 (fig. 3B), after lighting (par. 6.3.3), turn the

knob to the minimum (spark) and check that the burner is lit

along its entire length with flames at the lowest possible level.

Adjustments can be made by turning screw (7).

• Check that the pilot flames work properly.

• Copy the setup values on the data plate and place it in a suitable

spot.

• A servicing and maintenance contract is recommended.

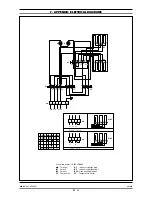

020_03

- GAS KITCHENS

12

· 23

03/2006

6

8

7

9

22

5

A

14

17

27

12 13 11

2 1

3

A

C - D

E

4

0

21

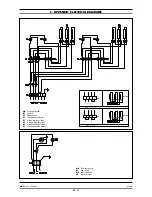

Fig. 1

Burners

Burner