3

Westward Operating Instructions and Parts Manual

6PAG3~ 6PAG9,

6PAH0~6PAH9, 6PAJ0~

6PAJ2, 10L414~10L424

Micrometer Torque

Wrench

General Safety Information

Your torque wrench was calibrated and tested before leaving the factory and is guaranteed

to meet or exceed ASME B107.14 standard.

Because your torque wrench is a precision measuring instrument, it should be serviced

only where skilled men and special tools and equipment are available.

Do not continue pulling on the wrench after pre-set torque has

been reached. Pressure must be taken off the handle and the wrench allowed to

automatically reset itself.

Ratchet mechanism may slip or break if dirty, mismatched or if

worn parts are used. Ratchets that slip or break can cause injury.

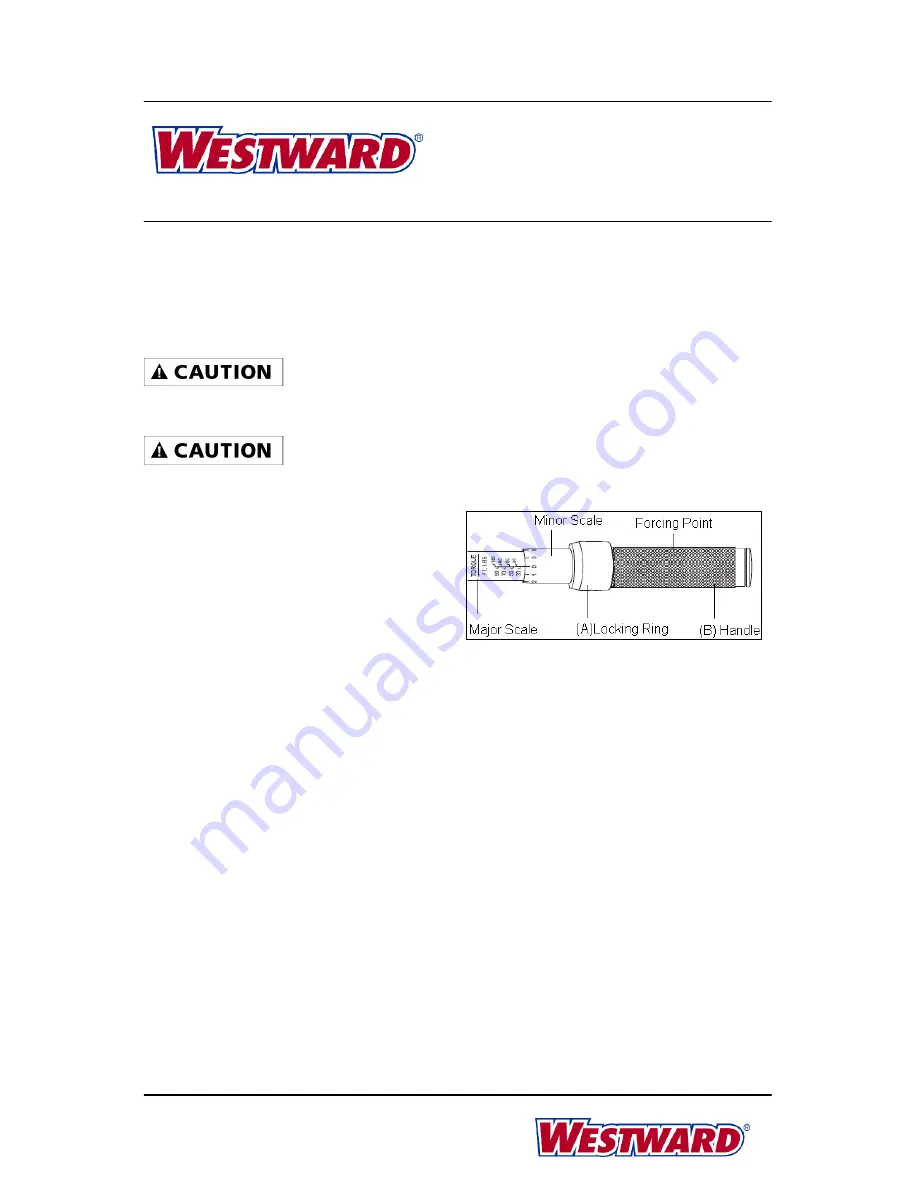

Operation

1.

To unlock the handle, hold the body

tube and pull the locking ring (A) back,

allowing the handle (B) to turn

clockwise or counterclockwise.

2.

Set the desired torque by turning the

handle. For example, 85 Ft-Lb.

a.

Pull the locking ring to adjust the torque.

b.

Turn the handle until the zero graduation on minor scale lined up with the vertical

line and is even with 80 Ft-Lb graduation.

c.

Turn the handle clockwise and set the minor scale to

“five (5)” on the vertical line.

Now the torque is set at 85 Ft-Lb.

3.

Release the locking ring to lock the handle.

4.

Install the proper socket or attachment to the square drive and apply to the object

being torqued. Applying a stead pull to the center of handle, and stop pulling until you

hear a

“Click” sound. The release is distinct and unmistakable. It can be felt as well

as heard. When pressure is removed from the handle, the torque wrench will

automatically reset itself.