28

CAUTION

It is hazardous to attempt drying out a transformer un·

less constant attention is given the job.

An

unattended

transformer could be destroyed if the coils are allowed to

overheat.

A recommended method of drying the windings and

insulation is by circulating current through the windings.

The LV winding should be short-circuited and sufficient

voltage impressed across the high voltage winding to cir

culate enough current through the coils to maintain the

coil temperature at 8 0°C to 9 0°C as measured by winding

resistance. About one-fifth of normal full-rated current is

generally sufficient to do this. The impressed voltage nec

essary to circulate this current varies within wide limits

among different transformers. This voltage will generally

be approximately

I

/2 percent to 1 - 1 /2 percent of the

normal voltage of the winding at normal frequency. The

cooling tubes or radiators should be blanketed to prevent

air circulation and thus heat loss. Otherwise , the power

requirements will be excessive .

The transformer should be placed in its case with the

liquid and with the handhole cover removed to allow free

circulation of the air in the gas space .

For complete information on determination of dryness

and additional methods of drying out, order Instruction

Leaflet 4 8 - 6 2 0-1.

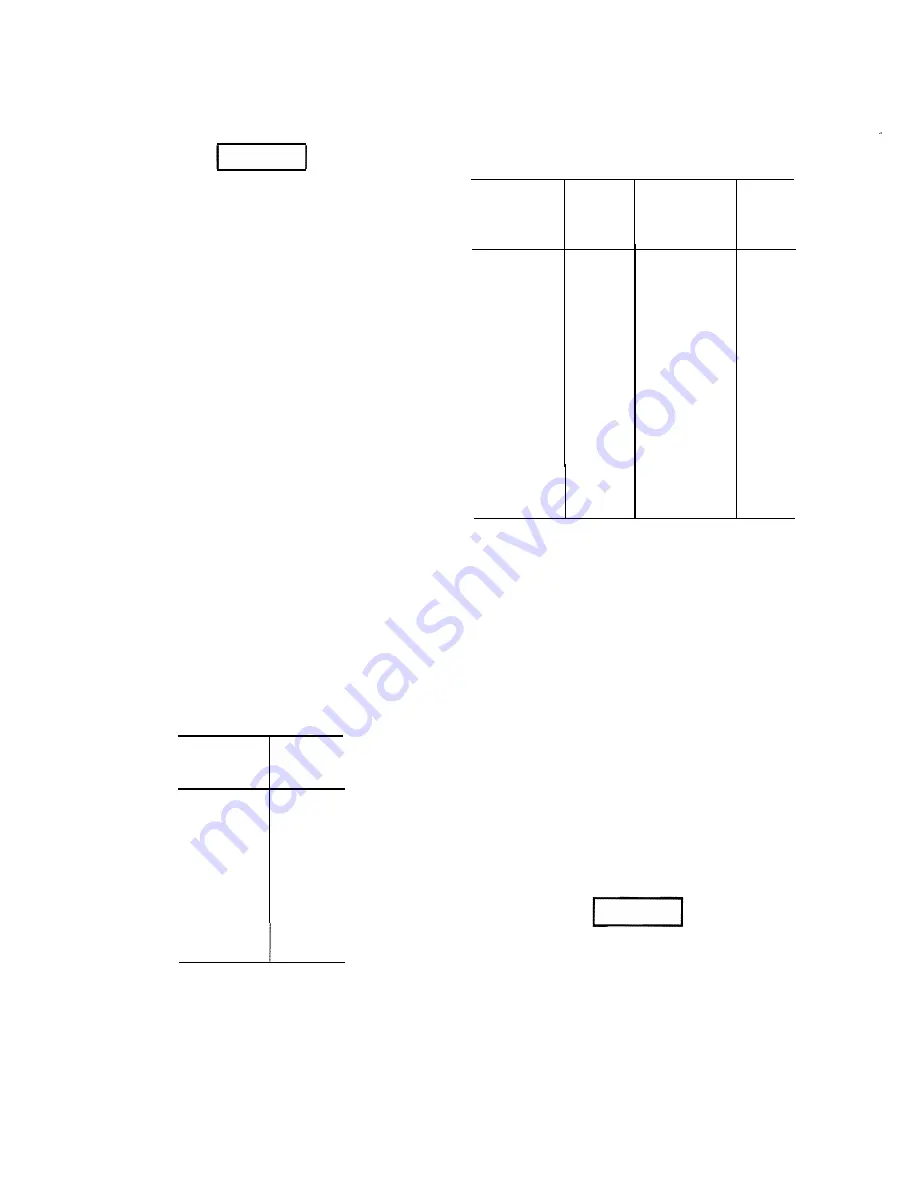

Minimum Insulation Resistance in Oil at 20°C

L-L Voltage

aass KV

Megohms

1 .2

3 2

2. 5

68

5

1 3 5

8 .66

2 3 0

15

4 1 0

2 5

6 7 0

34. 5

9 3 0

4 6

124 0

6 9

1 8 6 0

Fig.

1 8

8.4

Vacuum Filling of Transformer

The evacuation and liquid-filling operations specified in

the following are intended to be accomplished as contin

uous uninterrupted processes.

Insulation Resistance Temperature Correction

Transformer

Correc-

Transformer

Correc-

Tempera-

tion

Tempera-

tion

ture °C

Factor

ture °C

Factor

9 5

8 9 . 0

3 5

2.5

9 0

6 6.0

3 0

1.8

8 5

4 9.0

2 5

1.3

8 0

3 6 .2

2 0

1.0

7 5

2

6

. 8

1 5

0.7 3

7 0

2 0. 0

10

0.5 4

6 5

14. 8

5

0.4 0

6

0

1 1.0

0

0.3 0

5 5

8 . 1

- 5

0.22

s o

6

.

0

- 1 0

0. 1 6

4 5

4.5

- 1 5

0. 1 2

4 0

3.3

Fig.

1 9

During the vacuum and liquid -filling operations, the

temperature of the core and coils must be above 0°C

( 3 2°F). The temperature of the liquid when it is added to

the transformer during vacuum-filling, must be

I

0°C

(S 0°F) or higher.

When vacuum filling a transformer on which a Sudden

Pressure Relay is mounted , care must be taken that the

Relay is not filled with oil. Also pull vacuum and break

vacuum at 1 /4 psi/second maximum to avoid any possi

bility of straining the bellows. The Sudden Pressure Relay

must be correctly installed according to the instructions

in Section 5 . 1 0 to prevent failure during vacuum treat

ment. If the transformer is shipped with a dummy plate

mounted in place of the Sudden Pressure Relay , the

transformer should be filled with liquid before the Relay

is mounted.

CAUTION

Transformer oil should always be handled as a flammable

liquid. It should also be remembered that closed trans

former tanks may under some conditions accumulate ex

plosive gases, and that oil-handling procedures may gen

erate static electricity. Safety precautions should include

purging all gas spaces with nitrogen before oil-fdling or

ftltering and grounding the transformer, its bushings, and

all oil-handling equipment. Otherwise, static electricity

could ignite the oil.