11

FVD

FLOWZER VD - Transducer for automatic adjustment

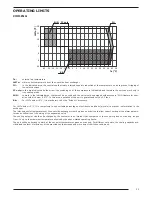

Flowzer VD requires a pressure transducer to be installed in the machine. Through this transducer, the inverter

can gauge the actual pressure at the ends of the system and automatically adapt the pump speed to obtain a

set available discharge head value. Flowzer VD must be combined with Flowzer VP.

This accessory therefore allows a constant pressure system to be achieved.

Q [l/s]

R

n’’’

n’’

n’

Q

min

n

Q

max

H

AV

[k

Pa

]

H

d

R’

R’’

R’’’

Q’’’

Q’’

Q’

Q

Pa

[k

W

]

Q’’’

Q’’

Q’

Q

n

n’

n’’

n’’’

Q [l/s]

With the Flowzer VD, the customer can set, directly on the inverter, the available discharge head value H

d

that

the unit must maintain.

As can be seen in the graph, as the system user points close, the resistance curve of the system shifts to the

left and therefore the inverter will be able to reduce the pump speed in order to keep the available discharge

head of the unit constant. By doing so, an immediate reduction in the power absorbed by the pump will be

obtained.

The customer will have to check that, in minimum flow rate conditions (that is, with the maximum number of

user points closed), this is always higher than or equal to the minimum flow rate allowed by the unit.

This accessory is useful when the total head losses of the circuit are slightly variable or when they change

depending on the seasons (for example, some user points are active only during summer operation and not

during winter operation).

The use of this accessory also allows the pump speed to be adapted to possible fouling of the filter on the

hydraulic circuit.

FLUS Flow switch (instead of the water differential pressure switch)

As an alternative to the differential pressure switch (standard flow sensor), it is possible to request the paddle

flow switch as accessory. This detects when there is no water flow to the user-side exchanger and sends a

signal to the control of the unit that will stop the compressors to prevent damage to the exchangers.

The flow switch is supplied loose (installation by the customer) and replaces the water differential pressure

switch (standard).

RA

Antifreeze heater …

These are electric heaters inserted on the user-side heat exchanger, on the pumps and in the tank (depending

on the configuration of the machine) to prevent damage to the hydraulic components due to ice formation

during periods when the machine is stopped.

The antifreeze heater is present as standard on the user-side heat exchanger alone.

VSIW Water-side safety valve (S)

With this accessory, a safety valve is inserted in the hydraulic circuit of the unit: when the calibration pressure

is reached, the valve opens and, by discharging (to be routed by the customer), prevents the system pressure

from reaching limits that are dangerous for the components present in the system. The valves have positive

action, that is, performance is guaranteed even if the diaphragm deteriorates or breaks.

The safety valve is inserted as standard on both hydraulic circuits.