Section BXB-19D-20A

030-100689 Rev. A

R

7

1009IARA

installed is at the bottom of the side car cabinet, the second

bolt installed is in the rear wall of the side car cabinet, then

repeat this alternating patterning by installing another

bolt at the bottom, then another at the rear wall, until all

bolts are installed). Tighten all bolts and nuts.

3.5.3

Mounting Conjoined Units on a Concrete Pad

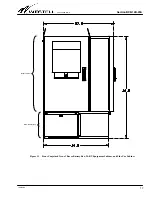

Follow the steps below to mount the conjoined Boxer cabinets

and battery box and on a concrete pad. Order and use the op-

tional A90-BXA-19PT2 Pad Mount Template Kit for mounting

on a concrete pad. Use the numbered steps below and the in-

structions in Figure 9 to mount the conjoined Boxer cabinets

and battery box on a concrete pad.

These instructions are guide-

lines; you must design, dig, mix, pour, and install the concrete pad

per local building codes and practices.

Note the following addi-

tional concerns for concrete pad installations:

S

Verify all required floor, ceiling, and wall cabinet knock-

outs have been removed (see the

KNOCK-OUT NOTE

and

Paragraph 3.5.1

)

, in all cabinets.

S

Select a mounting location that is dry, grade level or high-

er, and will support a 63" X 52" concrete pad (min). These

dimensions include 1 foot of concrete to extend out from

each side of the conjoined units.

S

If placing the concrete pad next to an adjacent structure,

Westell suggests a 24" distance between the cable access

door panel and any structure to allow for easy cable access.

Verify the cabinet doors can be fully opened.

- CONCRETE PAD MOUNT NOTE -

For concrete pad mounting, prepare and pour the concrete pad

(and install the accompanying conduit or ductwork) per local

codes and company practices, insert anchors in the wet concrete

precisely where holes at the bottom of the battery box are located

(holes are 0.344" in diameter), and allow the concrete to dry,

prior to mounting the Boxer units. Westell recommends using the

pad mount kit to facilitate precise anchor placement.

- CONCRETE PAD HEIGHT NOTE -

The pad location must be grade-level or above - it must not be be-

low grade-level. The location must be able to support the com-

bined weight of the conjoined Boxer cabinets/box and all internal

equipment, including batteries. Always follow local installation

codes, procedures, and practices.

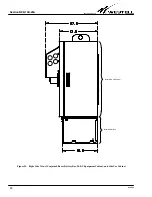

Concrete Pad Mounting Steps

1.

Determine exact concrete pad location.

Select and prepare

the location for the concrete pad, per company practice

and local codes. When determining the size of the pad, al-

low for 12" of concrete to extend out from

each

side of the

battery box (so the overall pad length and width measure-

ments are 2 feet wider than the battery box).

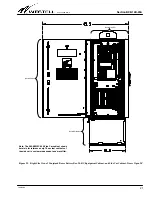

2.

Prepare template.

Perform Steps 1-3 of Figure 9.

3.

Prepare the pad for conduit or ductwork.

Dig and frame

the pad location per company practice. Once the pad is

framed for concrete, but before pouring gravel or con-

crete, install any cable conduit or ductwork that is desired

to be routed through the concrete and which will enter the

battery box from the bottom.

4.

Prepare the pad for concrete (add gravel).

Fill and com-

pact the pad site with gravel, per company practice.

5.

Prepare and join all Boxer units.

If not already done, per-

form the steps in Paragraph 3.5.2 to open all Boxer units,

to locate the bag of hardware in the battery box, to remove

knock-outs, and to join the units.

6.

Pour concrete, place the template, then set insulator gas-

ket and battery box on dry concrete.

Perform Steps 4-7 of

Figure 9 to pour the concrete, to place the template (with

anchors attached) on the wet concrete, and once the con-

crete dries, to place the insulator gasket and conjoined

Boxer units on the dry cured concrete.

7.

Test installation firmness.

Test the installation by attempt-

ing to move the conjoined units. Correct any looseness.

8.

Determine next step.

Proceed to Paragraph 3.6, 3.7, or 3.8

to make ground connections, to install conduit, ductwork,

fittings, and or cables, and make battery connections.

- GROUNDING NOTE -

Always follow local safety precautions and standard operating

procedures for grounding the equipment when installing, up-

grading, repairing or maintaining equipment. Any instructions or

information contained herein is subordinate to local codes, oper-

ating procedures or practices.

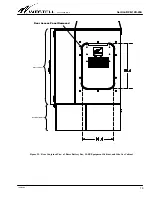

3.6

Making Ground Connections

As the battery box is designed to be mounted with a Boxer

equipment cabinet and side car cabinet, ground lugs and post

are not provided in the battery box itself, but instead provided

in the cabinets mounted above it. However, earth ground pro-

visions and connections must be considered when installing the

conjoined units, and earth ground should be brought up

through the bottom of the battery box similar to all other cable-

type access (such as electrical and signaling). Copper ground

lugs that accommodate #6 to #14 gauge wire are provided on

a ground plate on the interior floor of the Boxer equipment

cabinet (see Figure 10). Also on the plate are eight sets of bond

posts. One set of posts should be populated with a ground strap

to the side car cabinet.

To ground the battery box to the equipment cabinet’s ground

plate, two bonds straps (provided) must be installed, as ex-

plained in the steps that follow.

1.

Locate the bond straps.

Find the bond straps that are pro-

vided in the kit shipped with the battery box. One bond

strap is to be installed inside the battery box, and one is

installed in the cabinet, at the bottom. Note that each ring

end of each strap has a hole in it, and also note that one

hole is larger than the other.

2.

Install small end of the cabinet bond strap.

Install the ring

end with the smaller hole around a post on the Boxer

equipment cabinet’s ground plate.