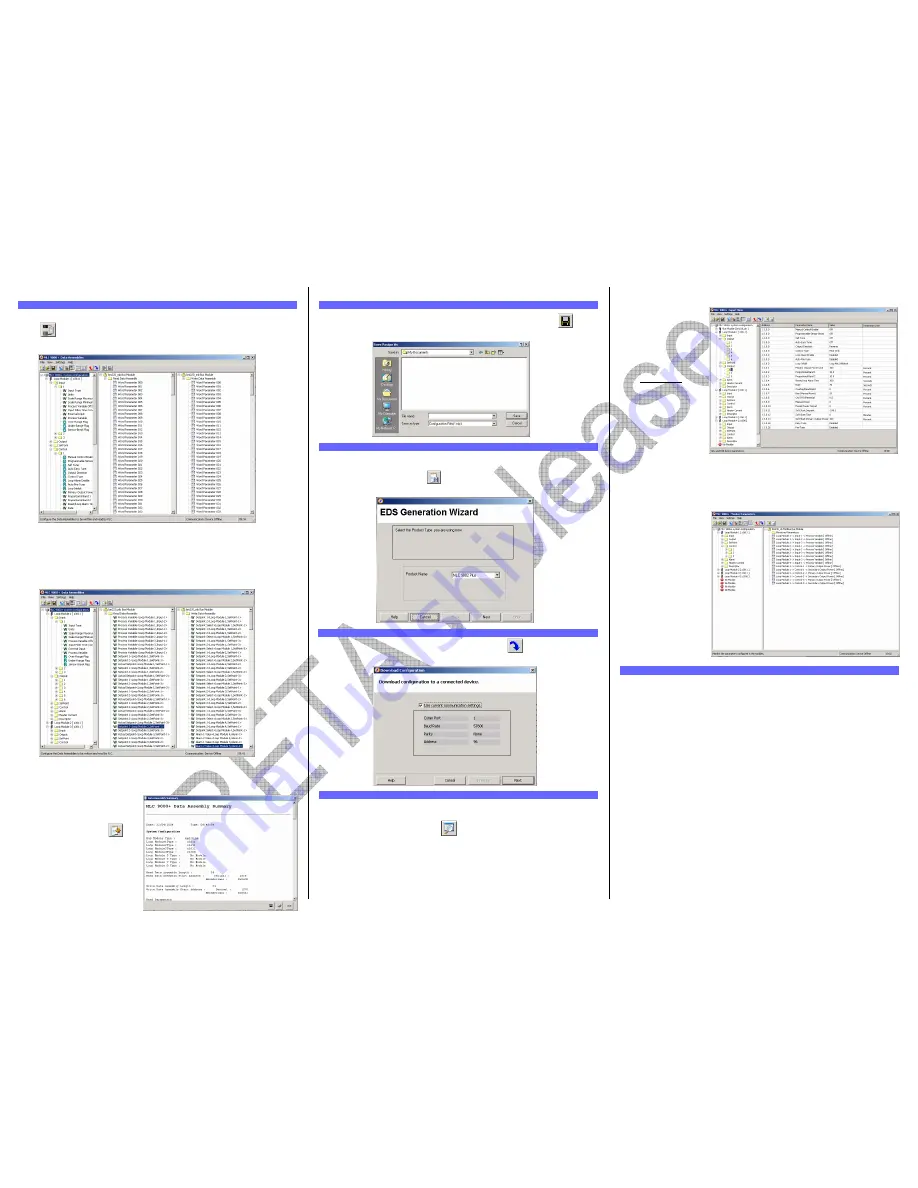

Select the Data Assemblies screen using View | Data Assemblies or the Data Assemblies

button.

A Data Assembly is a user-defined collection of parameters that the Bus

Module collects from its Loop Modules so that the master device (PLC, SCADA or HMI)

can collect the required parameter data in one message transaction.

There are two user definable data assemblies. These are 1)

Read

-

parameters that are to

be transferred from the MLC 9000+ to the supervisory system

and 2)

Write

-

parameters

that are to be transferred from the supervisory system to the MLC 9000+.

In the left hand column are all the parameters that can be mapped to the data assemblies

for transfer to or from the supervisory system and on the right are the two data assemblies.

To populate the data assemblies select a parameter from the list then drag and drop it into

the read or write tables. MLC 9000+ will not allow read only parameters to be placed into

the write data assembly.

Word parameters are shown with a

W

and bit parameters are shown with a

B

. If a bit

parameter is dragged onto a word register the register is converted into 16 bits. The full 16

bits can then be filled with any combination of bit parameters. If a word parameter is placed

into that bit register then it is then converted back to a word register and the bit

configuration is lost.

A summary of the data assembly

information can be created by

selecting the ‘summary’ icon

in

the tool bar

Once the system has been configured it can be saved by clicking on the save

icon in

the tool bar or navigate to File | Save as.

Some Fieldbus protocols require a GSD/EDS file for configuration of the master device.

MLC 9000+ Workshop generates this file once the data assemblies have been populated.

Click on the create GSD/EDS icon

in the tool bar this will activate the create

GSD/EDS wizard that will guide you through the creation of the GSD/EDS file.

To download the configuration to the MLC 9000+ click on the

icon in the tool bar, this

will activate the download wizard which will guide you through the download process.

The MLC 9000+ system can be adjusted using the expert view and monitored using the

Monitoring view.

Adjusting Parameters in Expert view

The expert view contains all the parameters that can be edited in a full system.

In the left hand column are the modules as configured in the system configuration, by

clicking on the + sign next to the module the tree view is expanded and all the parameter

classes are displayed.

When a class is selected all the parameters for that class are displayed on the right.

Clicking on the value of a parameter enables that parameter to be edited. When all

required parameter changes have been made the configuration can be download to the

MLC 9000+ by clicking on the Download configuration icon.

To work online select

Settings | Work Online.

This will then make the

expert view live so that

any changes made will be

downloaded to the MLC

9000+

immediately

.

WARNING:

Care must be taken when working online as changing certain parameters may

cause others to change automatically (i.e. when the input range is changed the scaling is

defaulted)

CAUTION:

When working online it is advised that steps are taken to ensure damaging

conditions can not be caused.

Monitoring View

In the left hand column are

all the parameters that can

be viewed, organised by

module and class. To

monitor a variable double

click the parameter name.

It will then appear in the

right hand column.

.

Your PC should meet the following minimum requirements for satisfactory operation of the

software:

Windows 2000

PC with 400 megahertz (MHz) or higher processor clock speed recommended; 133-MHz

minimum required;*

128 megabytes (MB) of RAM or higher recommended (64 MB minimum supported)

64 megabytes (MB) of available hard disk space.*

Super VGA (800 × 600) or higher resolution video adapter and monitor

CD-ROM or DVD drive

Keyboard and Mouse or compatible pointing device

Windows XP

PC with 800 megahertz (MHz) or higher processor clock speed recommended; 233-MHz

minimum required;*

256 megabytes (MB) of RAM or higher recommended (64 MB minimum supported)

64 megabytes (MB) of available hard disk space.*

Super VGA (800 × 600) or higher resolution video adapter and monitor

CD-ROM or DVD drive

Keyboard and Mouse or compatible pointing device

* Actual requirements will vary based on your system configuration and the applications

and features you choose to install. Additional available hard disk space may be required if

you are installing over a network.

6. CONFIGURING THE FIELDBUS COMMUNICATIONS (DATA ASSEMBLIES)

8. GENERATING THE GSD/EDS FILE

9. DOWNLOADING THE CONFIGURATION TO THE MLC 9000+

7. SAVING A SYSTEM CONFIGURATION

10. ADJUSTING AND MONITORING A LIVE SYSTEM

11. MLC 9000+ WORKSHOP SYSTEM REQUIREMENTS