5

INSTALLATION

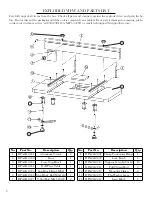

1. Unpack and assemble the drill press table according

to the Exploded View and Parts List on page 4. Refer to

the dimensions listed above to determine the space and

arrangements needed for your drill press table.

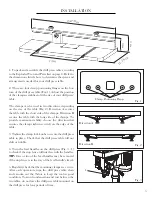

2. There are four clamp positioning flanges on the bot-

tom of the drill press table (Fig. 1). Adjust the position

of the clamp assemblies to fit the size of your drill press’

table.

The clamps can be used in two directions, depending

on the size of the table (Fig. 2). Direction A secures

the table with the short side of the clamps. Direction B

secures the table with the long side of the clamps. To

provide maximum stability, choose the direction that

ensures the clamps tighten securely on the edge of the

table.

3. Tighten the clamp lock knobs to secure the drill press

table in place. Check that the drill press table will not

shift or wobble.

4. Turn the feed handles on the drill press (Fig. 3 - 1)

to check if the stop fence will interfere with the handles.

TIP:

One or two of the feed handles may be removed

if the stop fence is in the way of the feed handle’s travel.

5. Regularly check that the mounting clamps are secure.

After each operation, wipe the drill press table clean

and vacuum out the T-slots to keep the tool in good

condition. To avoid condensation and rust between the

two tables, do not leave the drill press table mounted on

the drill press for long periods of time.

Fig. 1

Fig. 2

Fig. 3

Direction A

Direction B

Clamp Positioning Flange

1

11-7/8 in

.

23-7/8 in.

13 in.

4 in

.

5 in

.

Summary of Contents for DPA2412

Page 7: ...THANKS FOR REMEMBERING ...