WARNING:

To prevent serious injury from accidental operation, make sure that the saw is turned off

and unplugged from power source before installation, cleaning and maintenance operations.

MAINTENANCE

1. After every use, empty the water from the water tank and clean the water tank.

2. Clean the dust off the surfaces of the tool with a clean cloth or soft brush. Do not use alcohol, petrol or other

similar cleaning agents. Regularly check the tool and remove accumulated dust. Wear safety goggles to protect your

eyes while cleaning.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum based products, penetrating oils,

etc., come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic parts which

could result in serious personal injury.

3. Keep discs in good condition. Worn discs or discs in poor condition should be replaced before operation.

4. Apart from installing and replacing the diamond discs, there are no other user serviceable parts inside this tile

saw. Refer to qualified service technician if internal maintenance is required. Any worn, or damaged parts should be

replaced immediately by a qualified service technician.

TROUBLESHOOTING GUIDE

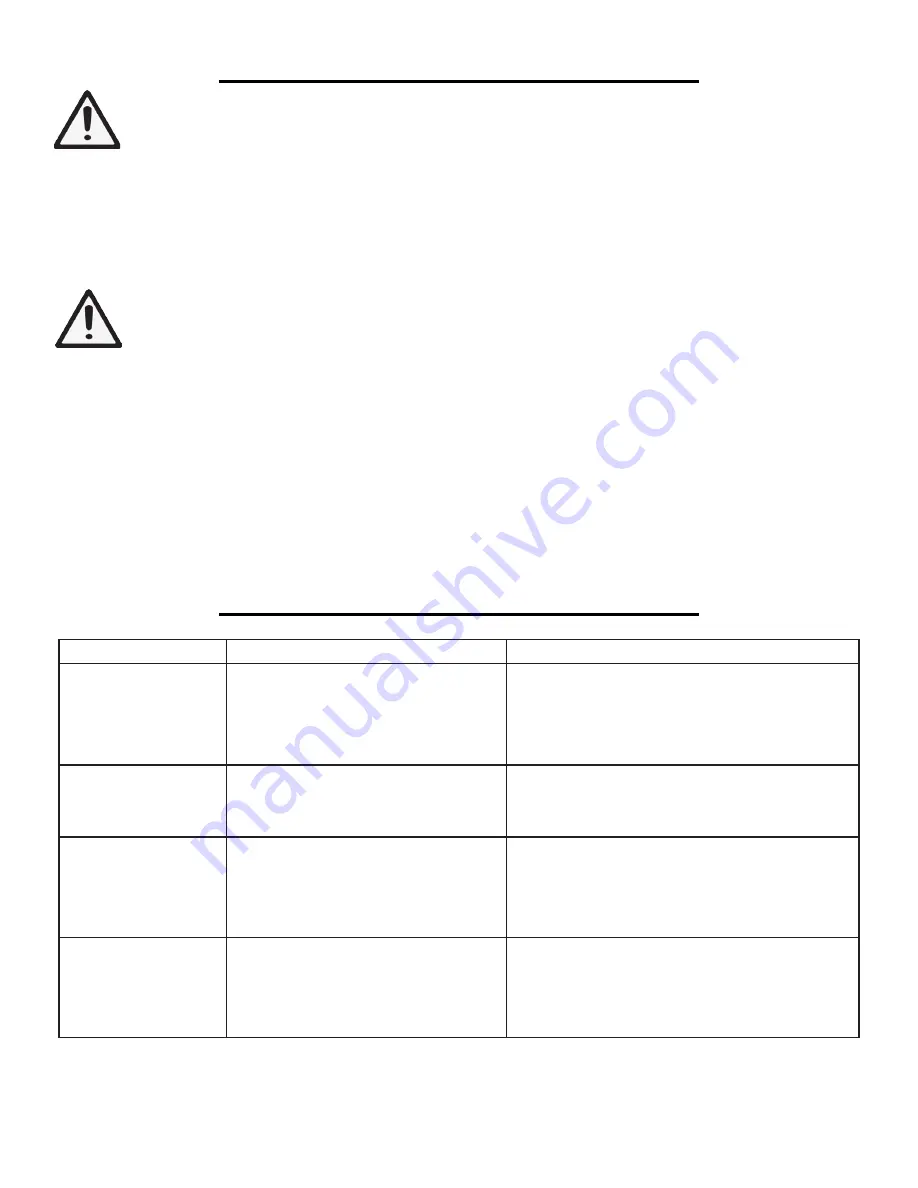

Problem

Possible Cause

Solution

Tool will not start

1. No power

2. Internal damage or wear (e.g. car-

bon brushes or switch)

1. Check power cord, power plug, power outlet

and fuse. Any damage in the power supply

should be service only by a qualified technician.

2. Have a qualified technician service the tool.

Motor runs, but cut-

ting disc remains still

when subject to load

Blade flange nut is loose

Check that the flange is seated correctly on

both sides of the blade and tighten if necessary.

Excessive vibration

1. Cutting disc warped or unbalanced

2. Cutting disc fitted incorrectly

1. Replace the cutting disc.

2. Fit the cutting disc correctly according to” In-

stalling the Diamond Disc And Metal Bracket”

on page 9.

Cutting disc is discol-

ored

1. Insufficient cooling water

2. Lateral friction caused by cut

runout

1. Fill the water tank with water up to the maxi-

mum fill line.

2. Guide the workpiece through the cutting disc

more slowly.

16

Summary of Contents for 71745

Page 20: ...THANKS FOR REMEMBERING ...