English

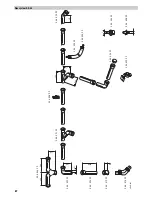

soldering bits, a Ø 7.0 mm hole must be tapped in the

required position, the push-on nipple must be screwed into it

and the vacuum hose from the FE soldering bits must then

be pushed onto the nipple.

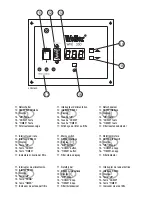

Electrical connection

The nominal voltage must be checked against the details

given on the nameplate prior to commissioning. If the mains

voltage is correct, connect the WFE 20D to the mains supply

(9) and switch on the equipment using the mains switch (11).

A green LED (filter is OK) indicates that the unit is running.

The percentage details for the turbine rotational speed are

shown on the display (13).

4. Operating the unit

Operating mode

The unit is in

mode 0

when it leaves the factory. Vacuum is

controlled to 8.000 Pa. This is the ideal setting for direct

extraction with WELLER FE soldering irons. Changes are not

possible in

mode 0.

However, if you require a different vacu-

um for control, this can be changed in setting mode 2 from

5.000 Pa to 8.000 Pa in steps of 100 Pa. (Display of 50 – 100)

Switching operating mode

Hold down the

UP

and

DOWN

(14/15) buttons simultaneous-

ly when switching on. The currently set operating mode is

shown in the display (ex works setting -0-). If the

TIMER

but-

ton (16) is additionally pressed, the unit can be switched to

mode 1 or mode 2. When the

UP

and

DOWN

button is

released, the unit starts in the set operating mode. In operat-

ing mode 1, the turbine is speed-controlled. The turbine

speed and thus the extraction power can be adjusted step-

lessly between 20% - 100% using the

UP/DOWN

button

(14/15). Setting mode 2 should only be used for modifying

the control setpoint. The unit should then be switched to

operating mode 0. Operating mode 0 now uses the modified

control setpoint.

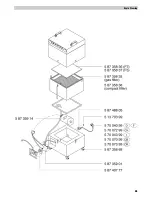

Filter checks

The filter status display (17) indicates when (through filter

differential pressure measurement) the permitted degree of

contamination has been exceeded and when the filter insert

has to be changed. The red filter control LED will illuminate

and the unit will be switched off. The sub-micron particle fil-

ter and wide-band gas filter are fitted one on the other, so

that they can be changed together as a compact filter.

The fine dust filter (8) (filter mat), is the pre-filter level of the

compact filter (7) and therefore has to be changed more

often. The pre-filter mat change is satisfactory, if the red LED

(17) is no longer illuminated when the equipment is switched

back on.

Displaying the filter operating hours

Press the

TIMER

button (16) and the current filter operating

hours will be displayed (display X 10). Flashing display. The

operating hours display must be manually reset after a filter

change. Keep the

TIMER

button (16) pressed down until the

display is reset to 000.

Filter operating hours default setting

The filter operating hours can be entered as a default setting

for better handling of the filter change intervals. When the

default operating hours setting has expired, the unit will be

switched off and “filter change required” will be indicated by

a flashing display (13) and the illumination of the red LED

(17).

Press the

TIMER

button (16) to enter the default operating

hours setting. The current filter operating hours will now

flash on the display. Press the

UP/DOWN

buttons (14/15)

simultaneously whilst the display is flashing. Release

UP/DOWN

buttons (14/15) and now use them to enter the

default operating hours.

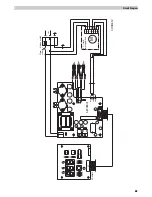

RS232 Interface

It is possible to control the WFE 20D via a PC using the inte-

grated standard RS232 interface (12). This enables the full

range of system functions to be used or remotely controlled.

Remote control

The remote control (which is available as an accessory) can

be operated via the RS232 interface (12). The unit’s main

functions can be transmitted using this remote control.

●

Switching the unit On/Off

●

Speed setting in mode - 1 -

●

Filter status display

Knowing that the WFE 20D can be operated via a remote

control is helpful when selecting the site for the unit.

Decommissioning

Attention!

A high concentration of pollutants will result in the

active carbon heating up. The equipment should be run

for several minutes in a pollutant free state before being

switched off in order to prevent unwanted heating up.

15

Summary of Contents for Zero-Smog WFE 20D

Page 3: ...WFE 20D...

Page 9: ...66 Explo Drawing...