Slide the heat exchanger through the front hole to the back hole. So that it protrudes

front

and

back.

Ideally the core of the heat exchanger will be entirely within the plenum. (Item B)

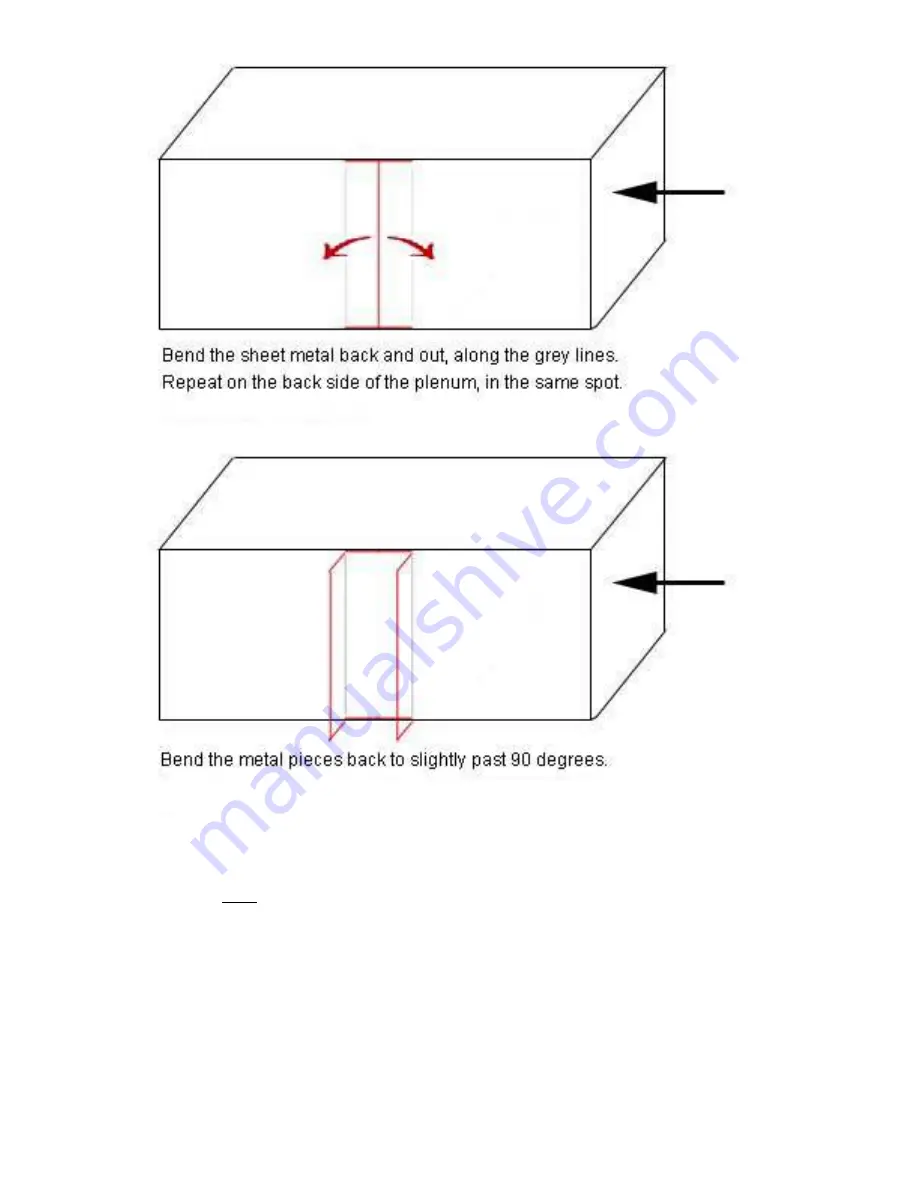

Crimp the sheet metal to the edge of the heat exchanger. This is item G in the diagram

above (Page 23). Using channel-lock pliers to crimp it, it makes a very nice professional

looking installation. Input lines should be at the bottom inlet unless otherwise marked.

This not only forms a virtually airtight seal, but it also supports the heat exchanger as

well.

27