WP13 Diesel Engine Series Operating Manual

7

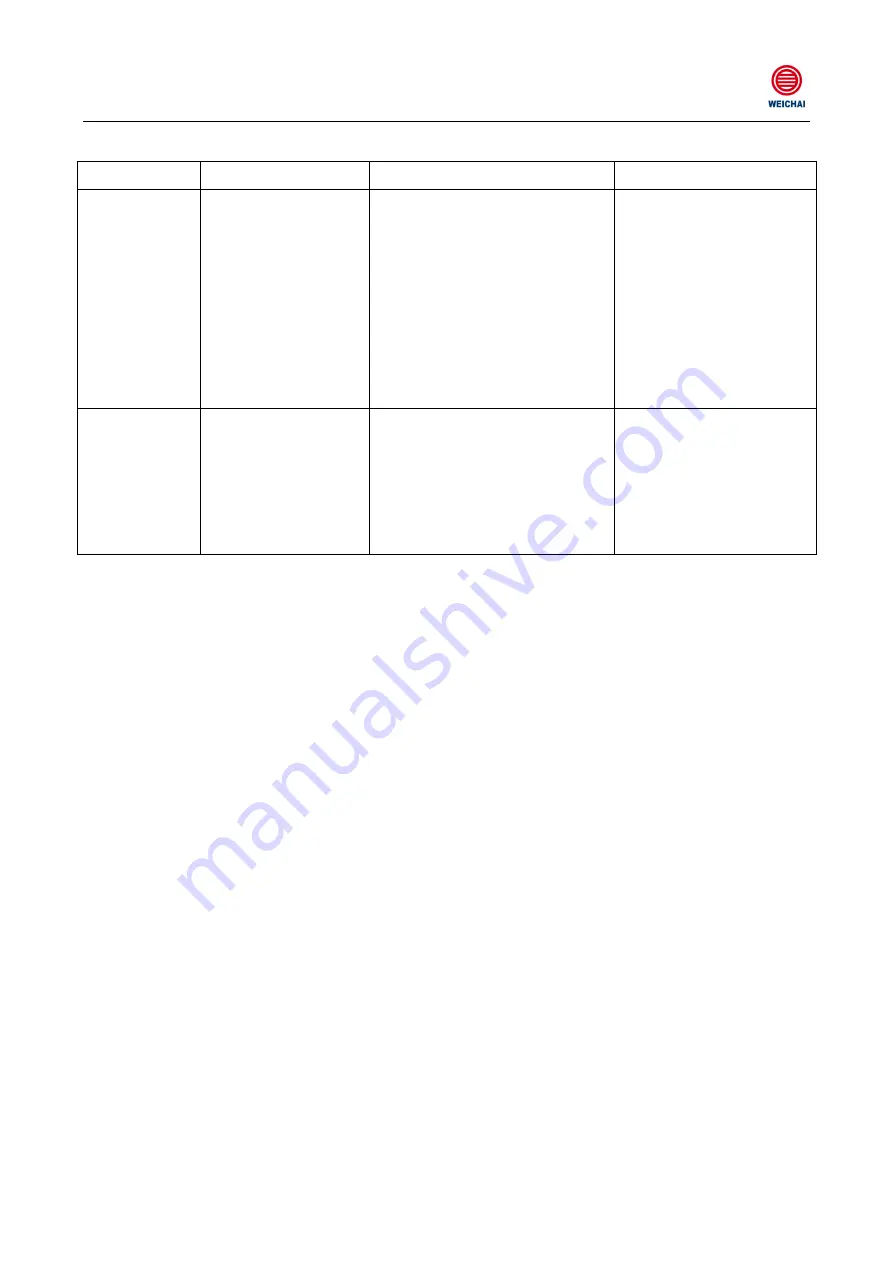

Table 3-3 References for Diesel Engine Sizing

Brand

Main uses

List for sizing parts

Additional remarks

Loctite 242

Coated on the thread

surface for fixing to

prevent looseness due

to shaking, medium

strength

Bolts of the oil filter base

Bolts of the oil cooler

Plug screws of the oil cooler

regulating valve

Bolts of the fixing device for the oil

pump return pipe

Compressor shaft end thread

Oil strainer bolts

Bolts of the fixing device for the

sensor and its wire harness

As an option, DriLoc204

thread pre-coating glue can

be used for precoating.

Loctite 518

(updated

product of 510)

Coated on polished

metal surface for

sealing

Joint surface between the oil filter

base and the crankcase

Joint surface between the cylinder

body and the engine oil cooler

cover

Joint surface between the cylinder

body and the oil filler cover plate

Chapter IV Use and Operation of Diesel Engine

4.1 Unsealing of the Diesel Engine

After the packing box of diesel engine is opened, the user should first make an inventory of the

diesel engine and its accessories according to the delivery packing list, and check whether the

engine has any visual damage, check whether there is any connector loose, and then complete the

following work:

◆

Wipe off the antirust coat of the exposed parts, as well as corrosion inhibitor, etc.;

◆

Drain the sealing oil in the fuel filter and the fuel system components (possibly, the engine can

be started before the sealing oil is drained, but only when the sealing oil in the fuel system has

been used up with normal fuel already available can you have the engine loaded for working).

Note: The diesel engine has its sealing effective period of one year, once longer than one year,

any engine should be checked, and additional measures should be taken when necessary.

◆

Rotate the flywheel and spray solvent into the intake manifold until the sealing oil in cylinder

is exhausted.

◆

Spray solvent into the turbocharger inlet and exhaust vent until the sealing oil is exhausted.

◆

According to the agreement between the manufacturer and the user, the oil sump shall be filled

with engine oil as required if there is no oil in it; if the oil sump has been filled with engine oil

containing running-in accelerant before delivery, it is recommended that the old oil should be

replaced after 2000 kilometers’ or 50 hours’ running.