5

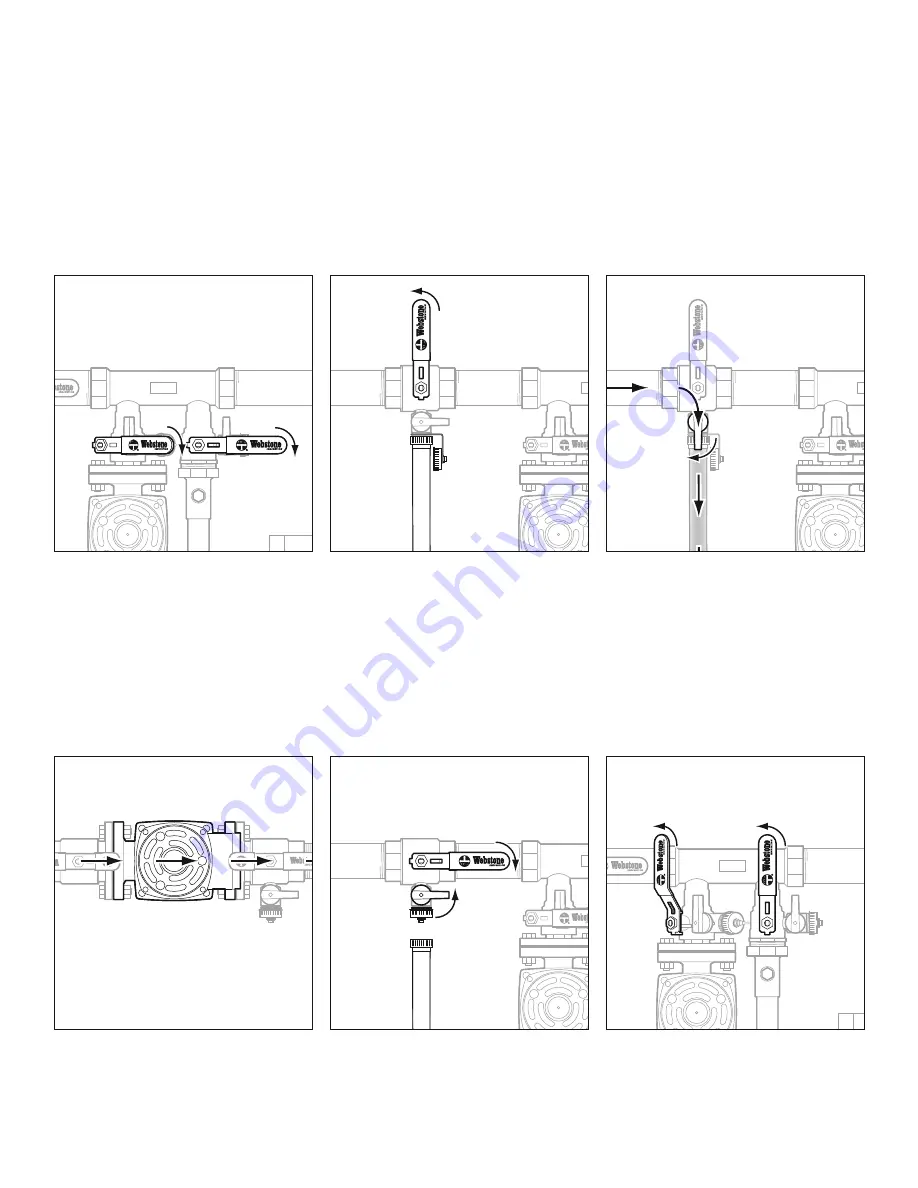

Secondary System Purging

Typically boiler manufacturers want to make sure that any foreign

matter (dirt, shavings, PTFE thread tape, etc.) is fl ushed out of the

Hydronic Piping System before fl uid begins to fl ow between the

boiler and the piping system.

To purge the secondary system the following is needed:

•

A hose w/ 3⁄4” hose thread connection

•

A water source

•

Power to the circulator pump in the secondary loop

1.

Turn the lever handles on both Hydro-

Core ball valves so that they are

parallel to the fl ange and the main

valves are in the closed position.

This will prevent any debris from

entering the near boiler loop during

fl ushing. If multiple circuits are

present, repeat for each circuit.

8.

Close the purging valve on the

drain in the secondary loop.

9.

Remove the hose and replace the cap.

10.

Open the main valve on the drain

valve in the secondary loop.

6.

Turn on the circulator pump in the

secondary system to purge the

entire loop with fresh water.

7.

Once the debris has been purged

out and the drainage from the hose

runs clear, turn off the circulator.

2.

Close the main valve and

remove the cap from the drain

valve in the secondary loop.

3.

Connect the hose to the

purging port on the drain valve

in the secondary loop.

4.

Direct the other end of the

hose into a bucket or drain.

5.

With the main water supply on

and fl owing into the system,

open the purging valve on the

drain in the secondary loop.

11.

Return the lever handled ball

valves on the Hydro-Core manifold

to their normal operating position

(handles perpendicular to the

fl ange). Repeat for each circuit.