Operating Instructions and Parts Manual

6

ELECTRICAL

Risk of electrical shock. This pump is designed

for indoor installation unless housed and protected from the elements.

Risque de choc électrique! Cette pompe est

conçue pour une utilisation à l'intérieur, sauf si elle est à l'abri et

protégée contre les intempéries.

•

This installation must be in accordance with the National Electric

Code and all applicable local codes and ordinances.

•

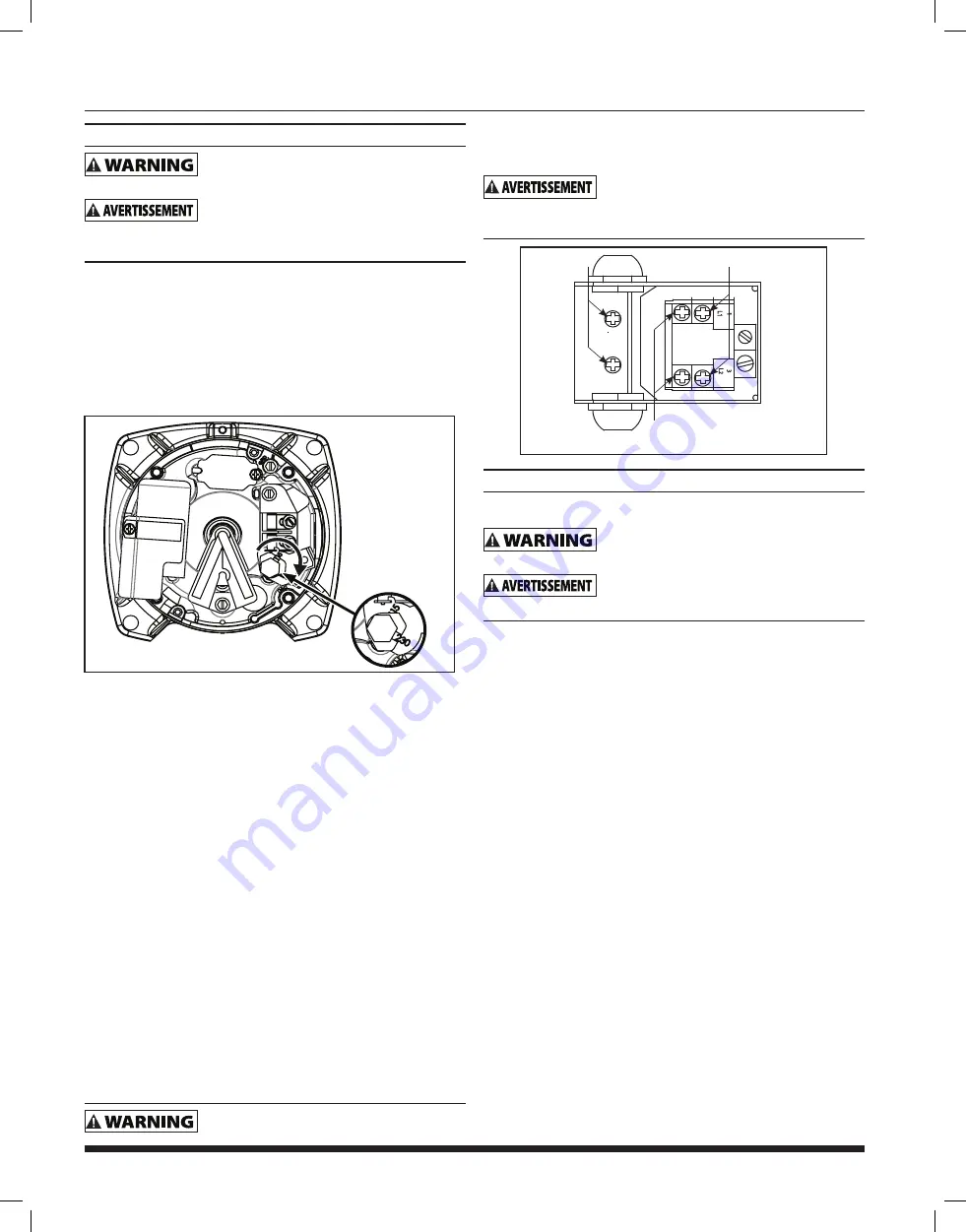

The voltage of power supply must match the voltage of the

pump. The motors can be converted to 115 or 230 volts by

changing the voltage selector to the desired voltage. Remove

rear cover of motor by unscrewing both screws to expose voltage

selector. Rotate dial so desired voltage is completely visible within

notch (Figure 4).

•

If wire run is a short distance, a cord/plug assembly may be used

as long as it meets the minimum wire gage size. Time delay fuses

are recommended over standard fuses for motor circuit protection.

All pump motors have built-in automatic overload protection that

will prevent damage to the motor due to overheating.

•

Do NOT connect to electric power supply until unit is

permanently grounded. Connect ground wire to approved ground

then connect terminal provided.

•

A metal underground water pipe or well casing at least 10 feet

long makes the best ground electrode. If plastic pipe or insulated

fittings are used, run a wire directly to the metal well casing or use a

ground electrode furnished by the power company.

•

There is only one proper ground terminal on the unit. The

terminal(s) is located under the pressure switch cover, is painted

green and is identified as GRD. The ground connection must be

made at this terminal (Figure 5). The ground conductor must not be

smaller than the circuit conductors supplying the motor.

Disconnect power and release all pressure from

the system before attempting to install, service, relocate or perform any

maintenance.

Débrancher de la source d’alimentation puis

dissiper toute la pression du système avant d’essayer d’installer, de

réparer, de déplacer ou de procéder à l’entretien.

L2 3

L1

1

Figure 5 - Electrical Connections

MOTOR

LINE

GROUND SCREW

OPERATION

PRIMING THE SHALLOW WELL PUMP

To prevent damage to the pump, do NOT start

motor until pump has been filled with water.

Pour éviter d'endommager la pompe, ne pas

démarrer le moteur tant que la pompe n'a pas été remplie d'eau.

1. Remove prime plug (Figure 3).

2. Fill pump and piping completely full of water.

3. Replace the prime plug.

4. Open a faucet to vent the system.

5. Start the motor. Water will pump in a few minutes. If pump fails

to prime in 5 minutes, stop motor and refill pump with water.

Priming time is proportional to the amount of air in inlet pipe.

6. Let the system operate for several minutes to flush all pipes.

7. Close faucet and allow pump to build pressure in tank. When

the pressure reaches the cut-out setting, the motor will stop.

The system is now in operation and will automatically cycle on

demand.

Figure 4 - Voltage Selector