2/2012

15019

r3

Please

Recycle

2800 De La Cruz Blvd.

Santa Clara, CA 95050

Phone: 800.879.8585

www.wattstopper.com

Sensor Parameters

Time Delay

20 minutes

Passive Infrared

Sensitivty

90%

Walk Through

OFF

TROUBLESHOOTING

Loads do not operate as expected.

LEDs don’t light, display is off

1. Check to see that the sensor is connected to the DLM local Network.

2. Check for 24VDC input to the sensor: Plug in a different DLM device at the sensor location. If the device does

not power up, 24VDC is not present.

• Check the high voltage connections to the room controller.

• If high voltage connections are good and high voltage is present, recheck DLM local Network connections

between the sensor and the room controller.

The wrong lights are controlled

1. Configure the sensor to control the desired lights using the Push n’ Learn adjustment procedure.

LEDs turn ON and OFF but load

doesn’t switch

1. Make sure device is not in PnL.

2. Check load connections to room controller.

WARNING:

TO CONNECT A COMPUTER TO THE DLM LOCAL NETWORK USE THE

LMCI-100.

NEVER CONNECT THE DLM LOCAL NETWORK TO AN ETHERNET PORT

– DOING SO MAY DAMAGE COMPUTERS AND OTHER CONNECTED EQUIPMENT.

Mounting plate

back view

European

3.5”

Octagon

4” Octagon

4” Square

2 Gang

2 Gang

1 Gang

European

3.5”

Octagon

4” Octagon

4” Square

2 Gang

2 Gang

1 Gang

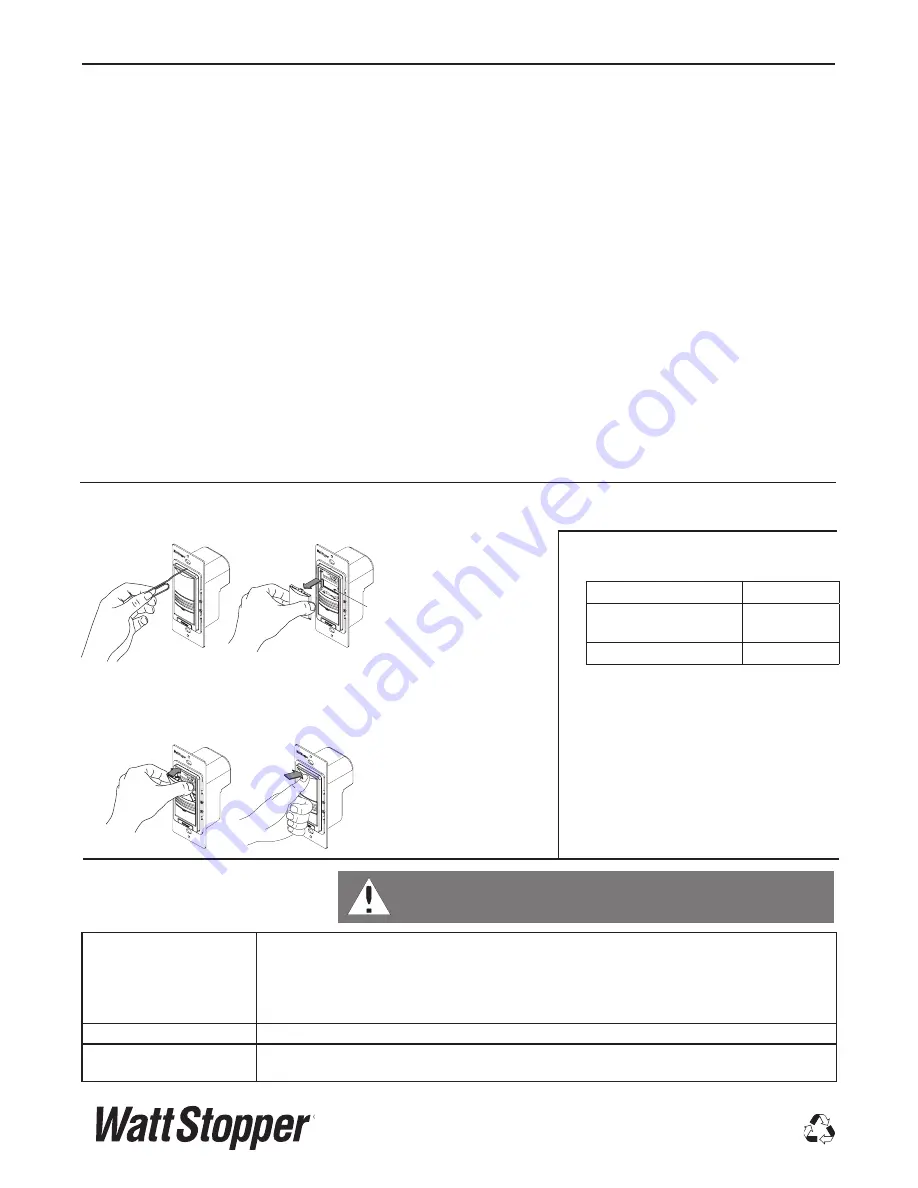

Using a screwdriver, punch out the

holes for the corresponding junction box.

J-box

Wall

Mounting plate

and base

LMRJ-C8 coupler

(included, LMRJ-S8 splitter optional)

Occupancy

Sensor

Snug

Ring

Wall

Snug

Ring

Secure

Snug

Ring

Loose

Screw

PLUG n’ GO OPERATION (PnG)

Each load is automatically assigned to a switch button.

•

If there is only one load it will default to Manual ON/Auto OFF. If there is more than one load then the first load

will default to Auto ON/Auto OFF and the rest of the loads will default to Manual ON/Auto OFF.

•

If there are

more buttons

than there are loads, the extra button(s) do nothing and blink when pressed.

• If there are

fewer buttons

than there are loads, the last button controls all remaining loads.

UNIT ADJUSTMENT - PUSH n’ LEARN (PnL)

Load Selection Procedure

A configuration button allows access to our patented Push n’ Learn™ technology to change the binding relationship between buttons and loads.

Step 1: Enter Push n’ Learn

Using a pointed tool, press and hold the configuration button for 3 seconds, until the Red LED on the switch begins to blink.

When you release the configuration button, the red LED on other communicating DLM Local Network devices begins to blink.

The DLM Local Network is now in PnL mode. The Red LEDs continue to blink until you exit PnL mode.

All loads in the room turn OFF after entering PnL. After one second, one load turns ON. This is Load #1, which is bound to button #1 as part of the

Plug n’ Go factory default setting.

The Blue LED will be ON for all buttons and sensors that are bound to this load.

Step 2: Load selection

Press and release the configuration button to step through the loads connected to the DLM Local Network. As each load turns ON note which

buttons and sensors are showing the blue LED. These devices are currently bound to the load that is ON.

To

unbind

a button from a load, press the button while its blue LED is ON. The blue LED turns OFF to indicate the button no longer controls the load

that is currently ON. Use the up and down arrow to bind and unbind the sensor.

Pressing the button again while the load is ON

rebinds

the load to the button and the blue LED illuminates.

Step 3: Exit Push n’ Learn

Press and hold the configuration button until the red LED turns off, approximately 3 seconds.

RELEASING LENS

Insert a small paper clip into the small hole at the top of the trim ring. Press in firmly until the lens is released and springs forward. Grab the lens and

remove it completely to expose the screen.

LCD

Screen

REINSERTING LENS

Reinsert the lens in the proper orientation: place the two posts at the bottom at a 30 degree

angle with the chamfered edge facing up. Gently press the top of the lens until it locks in

place.